Welcome fellow brewers! Today, I am excited to share with you my personal recipe for a 3-gallon beer that is sure to impress your friends and family.

Brewing beer is not just a hobby for me; it’s a passion that has been passed down through generations in my family. I truly believe that brewing beer is an art form, and every batch is an opportunity to create something unique and special.

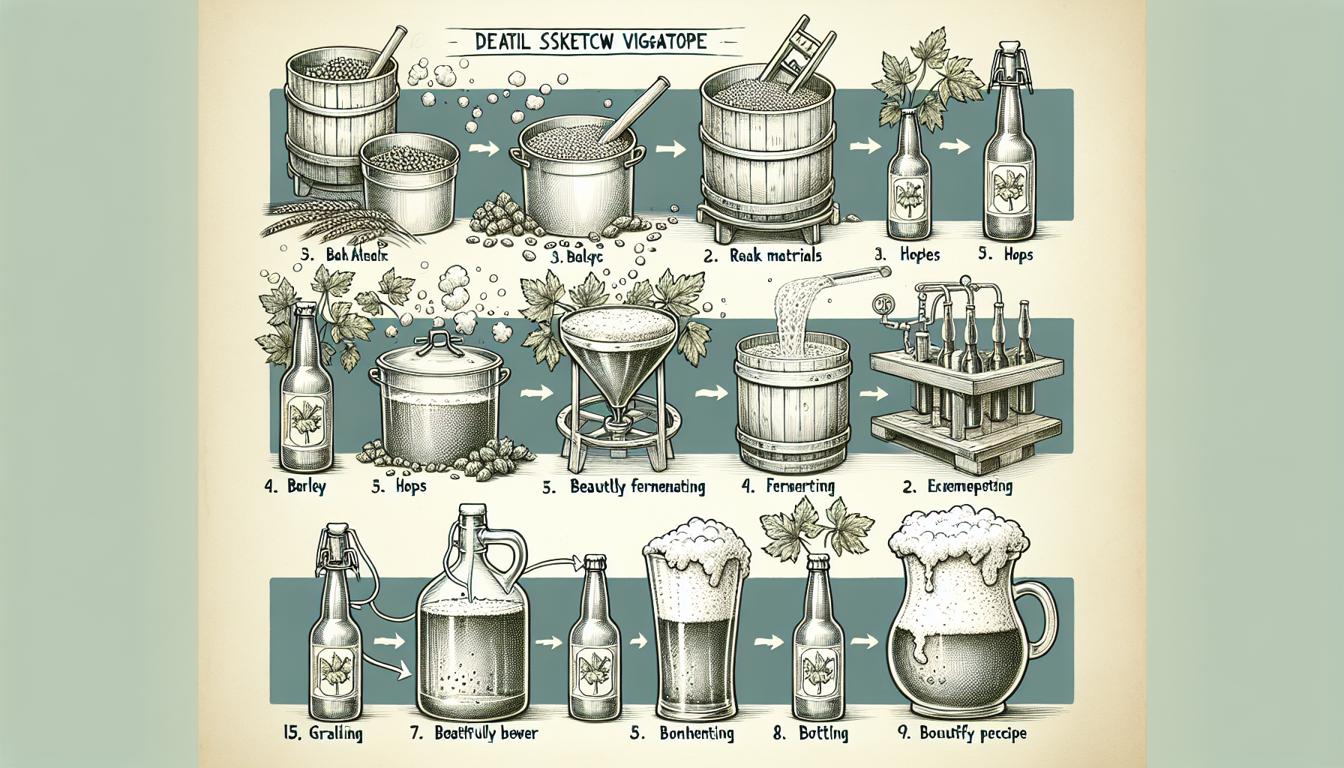

In this recipe, I will guide you through the entire brewing process, from selecting the right ingredients to the fermentation and bottling stages. So grab a pen and paper, because you’re about to embark on a brewing adventure!

Ingredients

Before we dive into the brewing process, let’s gather all the necessary ingredients. For this 3-gallon beer recipe, you will need:

– Grains: 6 pounds of a high-quality base malt, such as 2-row or Pilsner malt. This will provide the foundation for your beer and give it a nice malty flavor.

– Specialty Malts: 1 pound of specialty malts, such as caramel or chocolate malt. These malts will add depth and complexity to your beer, giving it a unique character.

– Hops: 1 ounce of bittering hops, such as Magnum or Chinook, for a nice hoppy bite. Additionally, 1 ounce of aroma hops, such as Cascade or Centennial, for a pleasant aroma. Feel free to experiment with different hop varieties to suit your taste.

– Yeast: 1 package of a high-quality yeast strain that complements the style of beer you’re brewing. Yeast plays a crucial role in fermentation and can greatly influence the flavor profile of your beer.

– Water: 4 gallons of clean, filtered water. Water quality is often overlooked in brewing, but it can have a significant impact on the final taste of your beer. If your tap water is not suitable for brewing, consider using bottled or distilled water.

– Optional Additions: Depending on the style of beer you’re brewing, you may want to add additional ingredients such as spices, fruits, or even oak chips. These additions can take your beer to the next level and add a unique twist.

Equipment

Now that we have our ingredients ready, let’s gather the necessary equipment for brewing a 3-gallon beer. Here’s what you’ll need:

– Brewing Kettle: A large kettle that can comfortably hold at least 4 gallons of liquid. Stainless steel is the preferred material for its durability and ease of cleaning.

– Mash Tun: A vessel that can hold the grains and hot water during the mashing process. A 5-gallon cooler with a false bottom or a stainless steel mash tun will work perfectly.

– Fermenter: A 5-gallon glass carboy or a food-grade plastic bucket with an airlock. Make sure it’s sanitized before use to prevent any unwanted bacteria or wild yeast from contaminating your beer.

– Siphoning Equipment: A racking cane or an auto-siphon to transfer the beer from the fermenter to the bottling bucket without disturbing the sediment.

– Bottling Equipment: A bottling bucket with a spigot, bottle filler, and enough bottles to hold your 3 gallons of beer. Don’t forget the bottle caps and a capper!

– Thermometer: A reliable thermometer to monitor the temperature throughout the brewing process. Accuracy is key when it comes to mashing and fermentation.

– Hydrometer: This tool measures the specific gravity of your beer and allows you to track the progress of fermentation. It’s a great way to ensure that your beer is fermenting properly.

– Sanitization Solution: A food-grade sanitizer, such as Star San or iodophor, to sanitize all your equipment. Sanitization is crucial in brewing to prevent any off-flavors or infections.

– Grain Mill: If you’re using whole grains, a grain mill will come in handy to crush them right before brewing. Freshly crushed grains will improve the efficiency of your mash.

Brewing Process

Now that we have all our ingredients and equipment ready, it’s time to start brewing! Brewing beer is a labor of love, and the process can be divided into several distinct stages. Let’s dive into each of them:

1. Crushing the Grains

If you’re using whole grains, it’s time to crush them. Crushing the grains right before brewing ensures maximum freshness and flavor extraction. Adjust your grain mill to achieve a medium crush, allowing for good water penetration during mashing without turning the grains into flour.

2. Mashing

The mashing process involves combining the crushed grains with hot water to extract the sugars and flavors. Here’s how to do it:

1. Heat 3.5 gallons of water to 160°F (71°C) in your brewing kettle.

2. Transfer the crushed grains to your mash tun and add the hot water. Stir well to ensure all the grains are evenly hydrated.

3. Check the temperature of the mash. It should be around 152°F (67°C) for most beer styles. If it’s too high, add a small amount of cold water to bring it down, or if it’s too low, add some hot water.

4. Close the lid of your mash tun and let it sit for 60 minutes. This is the time when the enzymes in the malt will convert the starches into fermentable sugars.

5. After 60 minutes, check the gravity of the wort using your hydrometer. It should be around 1.050 for most beer styles. If it’s too low, you may need to extend the mash time to extract more sugars.

6. Once the mash is complete, it’s time to sparge. Slowly pour 1 gallon of hot water over the grains to rinse off any remaining sugars. Collect the runoff in your brewing kettle.

3. Boiling and Hopping

Now that we have our sweet wort, it’s time to boil it and add the hops for bitterness and aroma. Here’s what to do:

1. Bring the wort to a rolling boil. This is an exciting moment in the brewing process, as the aroma of the malt fills the air. Keep an eye on the kettle to prevent any boil-overs.

2. Once the wort is boiling, add the bittering hops. This is where the magic happens. The bittering hops will add a pleasant hoppy bite to your beer and balance out the sweetness of the malt. Let them boil for 60 minutes.

3. After 60 minutes, add the aroma hops. These hops will contribute to the delightful aroma of your beer. Let them boil for an additional 10 minutes.

4. At the end of the boil, turn off the heat and cool the wort as quickly as possible. Rapid cooling is essential to prevent any off-flavors and to promote clarity in your beer. Use an immersion chiller or an ice bath to bring the temperature down to around 70°F (21°C).

4. Fermentation

Now that the wort is cooled, it’s time to transfer it to the fermenter and add the yeast. Follow these steps:

1. Sanitize your fermenter and all the equipment that will come in contact with the wort. Sanitation is crucial at this stage to prevent any unwanted bacteria or wild yeast from ruining your beer.

2. Transfer the cooled wort to the fermenter, leaving behind any trub or sediment at the bottom of the brewing kettle. A siphoning setup will make this process easier and minimize oxygen exposure.

3. Pitch the yeast into the fermenter. Follow the instructions provided by the yeast manufacturer for best results. Yeast is the workhorse of fermentation, converting the sugars into alcohol and carbon dioxide. Choose a yeast strain that complements the style of beer you’re brewing.

4. Attach an airlock to the fermenter to allow the carbon dioxide to escape while preventing any oxygen or contaminants from entering. Place the fermenter in a cool, dark place with a stable temperature.

5. Fermentation typically takes 1-2 weeks, depending on the style of beer and the yeast strain used. During fermentation, the yeast will produce alcohol, carbon dioxide, and various flavor compounds that give your beer its unique character.

5. Bottling

Once fermentation is complete, it’s time to bottle your beer. Follow these steps:

1. Sanitize all your bottling equipment, including the bottles, bottle filler, and bottling bucket. The last thing you want is to spend weeks brewing a delicious beer only to have it ruined by unsanitary bottling equipment.

2. Transfer the beer from the fermenter to the bottling bucket using a siphoning setup. Be careful not to disturb the sediment at the bottom of the fermenter.

3. Add the desired amount of priming sugar to the bottling bucket. Priming sugar is essential for carbonation in the bottle. Follow a priming sugar calculator to determine the correct amount for your beer style.

4. Attach the bottle filler to the spigot of the bottling bucket and fill each bottle, leaving about an inch of headspace. Cap the bottles using a capper.

5. Store the bottles in a cool, dark place for at least two weeks to allow for carbonation. Carbonation is a magical process that transforms your still beer into a lively, effervescent beverage.

6. After two weeks, it’s time to crack open a bottle and enjoy the fruits of your labor. Share it with friends and family, and don’t forget to take notes on the flavor, aroma, and appearance. Brewing is an iterative process, and feedback from others will help you improve with each batch.

Conclusion

Congratulations, you have successfully brewed a 3-gallon beer! I hope you enjoyed this recipe and found it informative. Brewing beer is an art form that requires practice, patience, and a touch of creativity. Remember to have fun along the way and embrace the learning process.

Feel free to experiment with different ingredients, hop varieties, and yeast strains to create your own unique recipes. Brewing beer is a journey, and there’s always something new to discover. Cheers to your brewing success, and may your beers always be tasty and satisfying!

Leave a Reply

You must be logged in to post a comment.