As an experienced homebrewer, I’ve always been intrigued by the science behind brewing and the various methods and techniques that can be used to achieve different results.

One such technique that has gained popularity in recent years is cold crashing, a process where beer is rapidly chilled to near-freezing temperatures for a short period of time, usually 24-48 hours, before bottling or kegging.

The main purpose of cold crashing is to clarify the beer by encouraging yeast and other particulate matter to settle at the bottom of the fermenter.

This can result in a clearer and cleaner final product. But what does this process do to the yeast?

Does cold crashing kill yeast? Let’s dive into the topic and explore what really happens to yeast during cold crashing, as well as the pros and cons of this technique.

Yeast Biology and Cold Temperatures

To understand how cold crashing affects yeast, it’s essential to look at the biology of yeast and how it responds to temperature changes. Yeast is a single-celled organism that reproduces by budding, and it’s responsible for converting sugars in wort into alcohol and carbon dioxide during fermentation.

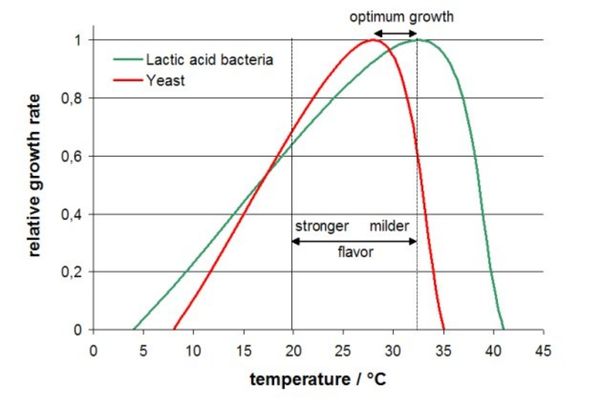

Yeast is a very temperature-sensitive organism. It thrives in a specific temperature range, which varies depending on the strain of yeast being used. For ale yeasts, the ideal fermentation temperature is typically between 60-75°F (15-24°C), while lager yeasts prefer temperatures between 45-55°F (7-13°C).

When yeast is exposed to temperatures outside of its preferred range, it can become stressed, leading to various problems in the fermentation process. On the higher end of the temperature spectrum, yeast can produce off-flavors due to increased ester and fusel alcohol production.

When the temperature drops too low, yeast can become dormant and slow down or even stop fermentation altogether. However, it’s important to note that cold temperatures do not kill yeast, but rather cause it to enter a state of dormancy.

Cold Crashing and Dormancy

When beer is cold crashed, the temperature drop shocks the yeast, causing it to enter a state of dormancy. In this dormant state, yeast cells stop reproducing and consuming sugars, and they become less buoyant.

This means that they are more likely to settle out of suspension and fall to the bottom of the fermenter.

It’s worth noting that while cold crashing does not kill yeast, it does reduce their overall activity. This means that if you plan to bottle condition your beer, you may need to add additional yeast at bottling time to ensure proper carbonation.

However, this is not always necessary, as there is often still enough viable yeast in suspension to carbonate the beer.

The Benefits of Cold Crashing

There are several advantages to cold crashing your beer before packaging. These include:

1. Improved clarity: Cold crashing encourages yeast and other particulate matter to settle out of suspension, resulting in a clearer final product.

2. Reduced sediment in bottles: By encouraging yeast to settle at the bottom of the fermenter, cold crashing can help reduce the amount of sediment in your bottles or kegs.

3. Faster maturation: Cold crashing can help speed up the maturation process of your beer, as the yeast has already settled out, and the beer has been exposed to cold temperatures.

4. Stabilization of flavors: Cold crashing can help stabilize the flavors in your beer, as it reduces the chance of further fermentation or changes in the beer’s composition due to yeast activity.

The Drawbacks of Cold Crashing

While cold crashing has its benefits, there are also some potential drawbacks to consider:

1. Risk of oxidation: When beer is exposed to cold temperatures, it can absorb more oxygen, which can lead to oxidation and off-flavors in the finished beer.

2. Potential for contamination: Cold crashing requires opening the fermenter and potentially exposing your beer to contaminants, such as bacteria or wild yeast, which can spoil your beer.

3. Additional equipment needed: To cold crash your beer effectively, you’ll need a temperature-controlled environment, such as a refrigerator or temperature-controlled fermentation chamber. This can be an additional expense and take up valuable space in your home brewery.

4. Potential impact on yeast health: While cold crashing does not kill yeast, it does cause them to become dormant, which may impact their overall health and vitality. This can be a concern if you plan to harvest and reuse your yeast for future batches.

Cold Crashing and Bottle Conditioning

One common concern among homebrewers is whether cold crashing will negatively impact bottle conditioning. As mentioned earlier, cold crashing does cause yeast to become dormant and settle out of suspension.

This can lead to concerns that there won’t be enough viable yeast left in the beer to properly carbonate it during bottle conditioning.

In most cases, there is still enough viable yeast in suspension to carbonate the beer, even after cold crashing. However, if you’re concerned about this, you can always add a small amount of fresh yeast at bottling time to ensure proper carbonation.

Cold Crashing and Reusing Yeast

Many homebrewers like to harvest and reuse yeast from previous batches to save money and maintain consistency in their brewing. Cold crashing can impact the health and vitality of the yeast, as they become dormant and settle at the bottom of the fermenter.

If you plan to reuse your yeast after cold crashing, it’s essential to ensure that you’re harvesting healthy, viable yeast. This can be done by collecting the yeast cake from the bottom of the fermenter and storing it in a sanitized container in the refrigerator. Before using the harvested yeast in a new batch, it’s a good idea to create a yeast starter to ensure that the yeast is still healthy and active.

Cold Crashing Alternatives

If you’re concerned about the potential drawbacks of cold crashing, there are alternative methods to clarify your beer and improve its appearance. These include:

1. Finings: Fining agents, such as gelatin or isinglass, can be added to your beer to help encourage yeast and other particulate matter to settle out of suspension.

2. Time: Simply allowing your beer to age and settle for an extended period can also help improve its clarity.

3. Filtration: Some homebrewers choose to filter their beer to remove yeast and other particulate matter, resulting in a clear final product.

Conclusion

In conclusion, cold crashing does not kill yeast but causes them to become dormant and settle at the bottom of the fermenter. While there are some potential drawbacks to cold crashing, such as the risk of oxidation and potential impact on yeast health, the benefits of improved clarity, reduced sediment, and faster maturation can make it an attractive option for many homebrewers.

As with any brewing technique, it’s essential to weigh the pros and cons and consider how cold crashing fits into your overall brewing process and goals. With proper care and attention to detail, cold crashing can be a valuable tool in creating high-quality, great-tasting beer.

FAQs

Does dry hopping affect fermentation?

No, dry hopping does not affect fermentation as it is done after primary fermentation is complete.

Can you reuse yeast after cold crashing?

Yes, you can reuse yeast after cold crashing. Cold crashing is a process of lowering the temperature of the beer to encourage yeast and other particles to settle at the bottom of the fermenter. Once the beer has been cold crashed, the yeast can be harvested and reused for future batches of beer. However, it is important to ensure that the yeast is healthy and free from contamination before reusing it.

Should you cold crash a yeast starter?

Yes, cold crashing a yeast starter can help to settle out the yeast and improve the clarity of the final product. It can also help to remove any unwanted flavors or aromas that may have developed during the fermentation process. However, it is important to ensure that the yeast has reached its desired level of activity before cold crashing, as this can slow or halt the fermentation process.

Should I dump yeast before dry hopping?

No, there is no need to dump yeast before dry hopping as the yeast can help to biotransform hop compounds and enhance the aroma and flavor of the beer.

How does dry hopping affect yeast?

Dry hopping does not directly affect yeast. However, it can indirectly impact yeast by altering the flavor and aroma of the beer, which can affect the yeast’s ability to perform its fermentation and attenuation functions.

Do you dump yeast before or after cold crash?

It is recommended to cold crash the beer first and then dump the yeast. This helps to settle any remaining yeast and other particles in the beer, allowing for a clearer final product.