Today, I want to share with you my love for 6-row barley beer and all the wonderful nuances that come with brewing this style. 6-row barley beer is a classic style that has a rich history and unique characteristics that make it stand out among other brews.

A Brief History Lesson

The use of 6-row barley in brewing can be traced back to ancient civilizations, particularly in Mesopotamia and Egypt. It was one of the first cultivated grains and was highly valued for its ability to grow in a variety of climates. Over time, it spread throughout Europe and eventually made its way to North America.

In the early days of brewing, 6-row barley was the primary grain used due to its higher protein content and enzymatic power. However, as brewing techniques evolved, 2-row barley became the preferred choice for many brewers. Despite this shift, 6-row barley beer continued to be brewed by those who appreciated its unique flavor profile and characteristics.

Key Characteristics of 6-Row Barley Beer

Now, let’s dive into what makes 6-row barley beer so special. One of the key characteristics of this style is its full-bodied and robust flavor. The higher protein content in 6-row barley contributes to a thicker mouthfeel and a more pronounced malt profile. This can result in a beer that is slightly sweeter and maltier compared to beers brewed with 2-row barley.

Another characteristic of 6-row barley beer is its higher enzymatic power. The extra enzymes present in 6-row barley can help break down complex sugars more efficiently during the mashing process. This can lead to a more complete fermentation and a beer with a higher alcohol content.

Additionally, 6-row barley has a slightly higher diastatic power compared to 2-row barley. This means that it has a greater ability to convert starches into fermentable sugars. This can be advantageous for brewers who want to experiment with different adjuncts or higher gravity beers.

Brewing a 6-Row Barley Beer

Now that we understand the history and characteristics of 6-row barley beer, let’s dive into the brewing process. As with any beer style, it’s important to start with high-quality ingredients and maintain a clean and sanitary brewing environment.

Here’s a step-by-step guide to brewing your very own 6-row barley beer:

Ingredients:

- 10 lbs 6-row barley malt

- 1 lb specialty malt (optional, for added complexity)

- 1 oz hops (bittering)

- 1 oz hops (aroma)

- Yeast of your choice

- Priming sugar (if bottling)

Step 1: Mashing

Begin by crushing the 6-row barley malt. This will help expose the inner starches and enzymes, allowing for better extraction during the mashing process. You can use a grain mill or your local homebrew shop can crush the grains for you.

Heat your brewing water to around 152°F (67°C) and add the crushed grains to your mash tun. Aim for a mash thickness of around 1.25-1.5 quarts of water per pound of grain. This will help maintain a good balance between enzymatic activity and sugar extraction.

Allow the grains to steep in the hot water for about 60 minutes, stirring occasionally to ensure even temperature distribution. This will allow the enzymes to convert the starches into fermentable sugars.

Step 2: Lautering and Sparging

After the mash is complete, it’s time to separate the liquid wort from the spent grain. This process is known as lautering. Slowly drain the wort from the bottom of the mash tun, being careful not to disturb the grain bed.

Once the wort is separated, you can begin the sparging process. This involves rinsing the grain bed with hot water to extract any remaining sugars. The sparge water should be heated to around 170°F (77°C) to help dissolve and rinse away the sugars.

Step 3: Boiling and Hops

Transfer the wort to your brew kettle and bring it to a rolling boil. This is where the magic happens! Add the bittering hops and start a timer for the desired length of the boil, typically 60 minutes.

After about 45 minutes, add the aroma hops to infuse the beer with their delightful fragrance. This will give your 6-row barley beer an extra layer of complexity and aroma.

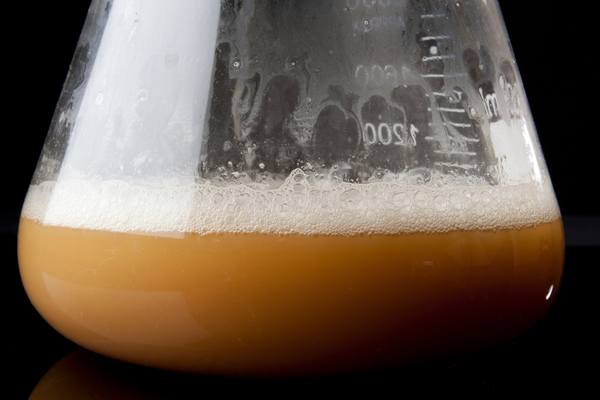

Step 4: Fermentation

Once the boil is complete, it’s time to cool the wort and transfer it to your fermentation vessel. Use a wort chiller or an ice bath to rapidly cool the wort to a temperature appropriate for your chosen yeast strain.

Pitch the yeast into the cooled wort and seal the fermenter with an airlock. Place the fermenter in a cool, dark place and allow the yeast to work its magic. Fermentation times can vary depending on the yeast strain and desired outcome, but typically range from one to two weeks.

Step 5: Bottling or Kegging

Once fermentation is complete, it’s time to package your 6-row barley beer. If you’re bottling, dissolve the appropriate amount of priming sugar in a small amount of boiling water and add it to the beer. This will create carbonation during the bottle conditioning process.

Transfer the beer to clean, sanitized bottles and cap them securely. Allow the bottles to condition at room temperature for two to three weeks before enjoying the fruits of your labor.

If you’re kegging, transfer the beer to a sanitized keg and carbonate using your preferred method. This will allow you to enjoy your 6-row barley beer on draft, with the added benefit of being able to adjust carbonation levels to your liking.

Conclusion

Brewing a 6-row barley beer is a rewarding experience that allows you to explore the unique characteristics of this classic style. The full-bodied flavor, higher enzymatic power, and robust malt profile make 6-row barley beer a standout choice for brewers who appreciate complexity and depth.

When brewing a 6-row barley beer, pay attention to the quality of your ingredients, maintain a clean and sanitary brewing environment, and follow the steps outlined above. With a little patience and attention to detail, you’ll be rewarded with a delicious brew that highlights the best qualities of 6-row barley.

So, gather your brewing equipment, select your favorite 6-row barley malt, and embark on a brewing journey that is sure to leave you with a beer that is rich in flavor and history. Cheers, my friends, and happy brewing!

FAQs

Which is better 2 row or 6 row barley?

The choice between 2 row and 6 row barley depends on the specific needs and preferences of the brewer. 2 row barley generally has larger kernels and higher starch content, which can result in better extract efficiency and higher alcohol potential. It also tends to have a more uniform and consistent flavor profile.

On the other hand, 6 row barley has smaller kernels and higher protein content, which can be advantageous for brewers who want to enhance the body and head retention of their beer. Ultimately, it is important for brewers to experiment and determine which type of barley best suits their desired brewing outcomes.

How much barley is needed for beer?

The amount of barley needed for beer production varies depending on the specific recipe and desired characteristics of the beer. On average, a standard beer recipe typically requires around 3-5 pounds (1.4-2.3 kilograms) of barley per gallon (3.8 liters) of beer. However, this can vary significantly depending on factors such as the beer style, desired strength, and other ingredients used in the brewing process.

Why do brewers typically prefer 2 row barley instead of 6 row?

Brewers typically prefer 2 row barley instead of 6 row because 2 row barley has larger kernels, lower protein content, and a higher starch-to-protein ratio, which leads to better fermentation and higher extract potential, resulting in a cleaner and more efficient brewing process.

What is the ratio of barley to water for beer?

The ratio of barley to water for brewing beer varies depending on the specific recipe and desired beer style. However, a common ratio is typically around 1 pound of barley to 1.5-2 gallons of water.

What is the difference between two row barley and six-row barley?

The main difference between two-row barley and six-row barley lies in the arrangement of the grains on the barley spike. Two-row barley has two rows of grains on each spike, while six-row barley has six rows of grains. Additionally, two-row barley tends to have larger grains and a higher starch content, making it more desirable for brewing and malting purposes. On the other hand, six-row barley has smaller grains and a higher protein content, making it preferable for animal feed and certain food products.

What are the benefits of 6 row barley?

One of the benefits of 6 row barley is that it tends to have higher protein content compared to 2 row barley. This makes it a preferred choice for brewers who want to achieve higher levels of protein in their beer. Additionally, 6 row barley has a higher enzyme content, which can aid in the conversion of starches to sugars during the mashing process. This can result in improved fermentability and higher alcohol content in the final product.

-recipe.jpg)

Leave a Reply

You must be logged in to post a comment.