Ah, Krausen, one of the most fascinating and dynamic stages in the brewing process! As an experienced brewer, I’ve had the pleasure of witnessing the beauty and complexity of Krausen many times. It’s a phase that occurs during fermentation and holds great significance in determining the quality and character of the final beer.

Krausen is the thick, foamy head that forms on top of the fermenting beer. It is composed of proteins, hop compounds, and yeast cells that rise to the surface as the yeast ferments the sugars present in the wort. This bubbling, frothy layer is a visual indicator that fermentation is in full swing.

The Krausen stage typically begins a few hours after pitching the yeast and lasts for several days, although the exact duration can vary depending on the yeast strain, fermentation temperature, and the specific beer style being brewed.

It’s during this time that the yeast actively consumes the sugars and produces alcohol, carbon dioxide, and various flavor compounds.

One of the fascinating aspects of Krausen is its ever-changing nature. Initially, the Krausen appears as a thin layer of foam, but as the fermentation progresses, it thickens and becomes more pronounced.

The aroma emanating from the Krausen is intense and distinct, often described as fruity, spicy, or even slightly sulfurous, depending on the yeast strain used.

As a brewer, monitoring the Krausen provides valuable insights into the fermentation process. A healthy and vigorous Krausen indicates that the yeast is actively converting the sugars and producing the desired flavors and aromas.

It’s a sign of a well-balanced fermentation and gives me reassurance that the beer will turn out great.

However, it’s important to keep a watchful eye on the Krausen, as excessive foaming can pose challenges. If the Krausen rises too high, it may overflow from the fermenter and create a messy situation. To prevent this, brewers often employ various techniques like using a blow-off tube or employing a larger fermentation vessel with ample headspace.

Once the Krausen begins to subside and the bubbling activity slows down, it indicates that the primary fermentation is nearing completion. At this point, I’m careful not to disturb the beer unnecessarily, as any oxygen exposure could negatively impact the final product.

In summary, Krausen is a captivating stage in the brewing process that showcases the vitality of the yeast and the magical transformation of wort into beer.

It’s a testament to the art and science of brewing, and each Krausen I’ve witnessed has left an indelible mark on my brewing journey, reminding me of the wonders and complexities of this craft.

5 Facts About Krausen in Beer:

- ✅ Krausen is a foamy head that forms on the surface of beer during fermentation.

- ✅ The term “high krausen” refers to the peak phase of fermentation when the beer is at its maximum foamy head.

- ✅ Krausen is composed of living and dead yeast cells, proteins, hop particles, and carbon dioxide.

- ✅ Krausen can vary in color, including brown, off-white, or white, depending on the ingredients used in the beer.

- ✅ Krausen typically falls and clarifies the beer as yeast flocculates and settles to the bottom of the fermenter.

Understanding krausen in beer brewing is essential for any beer enthusiast. In this section, we will explore the definition of krausen and highlight the importance of comprehending its role in the brewing process.

By digging into the details, we can uncover fascinating insights about this frothy phenomenon and gain a deeper appreciation for how it contributes to the creation of a perfect pint.

What is Krausening in Beer Brewing?

Krausen is a key element in the process of beer brewing. It refers to the foaming that occurs on top of fermenting beer due to the active fermentation of yeast and the release of carbon dioxide.

This foam is formed by a combination of proteins, hop compounds, and yeast cells, creating a thick layer on top of the beer.

During fermentation, the active yeast plays a vital role in krausen formation. As the yeast consumes sugars in the wort, it produces alcohol and carbon dioxide. The release of carbon dioxide causes bubbles to form within the liquid, eventually rising to the surface and creating krausen.

The presence of active yeast is essential for this process as it ensures proper fermentation and contributes to the overall quality of the beer.

In addition to yeast activity, unisomerized hop bitter compounds also influence krausen formation. These compounds are present in hops before they undergo heat treatment during brewing.

When added to the wort during boiling or dry hopping, these compounds can contribute to the stability and longevity of krausen. Their interaction with proteins in the liquid enhances foam formation and creates a more robust krausen layer.

It is worth noting that different stages can be observed during krausen development. The high krausen stage is characterized by an intense foaming activity at its peak, indicating active yeast metabolism.

This stage typically lasts for several days before transitioning into a low krausen stage where foam activity begins to subside. Finally, during the crashing krausen stage, which may last for several weeks, any remaining foam collapses as fermentation nears completion.

Understanding and managing krausen throughout the brewing process is crucial for producing high-quality beer. Krausen plays a significant role in metabolizing yeast cells, ensuring their health and vitality during fermentation.

Additionally, it contributes to natural carbonation by producing carbon dioxide gas as a byproduct of fermentation.

To manage krausen height, brewers employ techniques such as adjusting fermentation temperature, using specialized yeast strains, and employing proper yeast nutrient levels.

Additionally, blow-off tubes can be used to prevent krausen blowouts, where excessive foaming can lead to loss of beer and potential contamination.

The impact of krausen on beer quality extends beyond fermentation. Krausen has a direct influence on the flavor and aroma profile of the finished beer. The compounds found in krausen contribute to the overall complexity and character of the brew.

Furthermore, a uniform head of foam is highly desired in beer as it enhances the drinking experience by releasing aromatic compounds and improving mouthfeel.

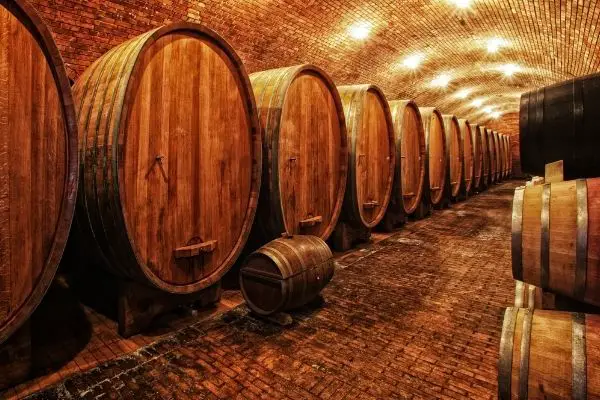

Traditionally, krausen has been significant in various brewing practices. In Bavaria, beer purity laws enforced the use of fresh krausen from a previous batch for carbonation and attenuation purposes. This helped maintain consistency and ensured that only quality ingredients were used in brewing.

Similarly, traditional fermentation cellars provided an ideal environment for krausen development due to their cool temperatures and natural carbonation capabilities.

Importance of understanding krausen in beer brewing

Krausen, a foamy substance that forms during the fermentation process in beer brewing, holds significant importance. Understanding krausen allows brewers to make informed decisions throughout the brewing process, resulting in better quality beer.

The formation of krausen is influenced by active yeast and unisomerized hop bitter compounds. It goes through different stages – high krausen, low krausen, and crashing krausen. Krausen plays a vital role in metabolizing yeast cells and producing carbon dioxide.

Managing krausen height is crucial, as it can affect the flavor and aroma of the final product. Traditional techniques like Bavarian beer purity laws and fermentation cellars have long recognized the importance of krausen in achieving superior beer quality.

The Formation of Krausen: Where yeast and hops join forces to create a frothy spectacle that even Shakespeare would raise his pint to.

The Formation of Krausen

During the brewing process, krausen forms on top of the fermenting beer, playing a crucial role in its development. In this section, we will explore the formation of krausen and its significance.

Discover how active yeast contributes to krausen formation and learn about the influence of unisomerized hop bitter compounds on this frothy layer.

These insights shed light on the intricate processes occurring within our favorite brews. (Reference Data: The Formation of Krausen)

Role of active yeast in krausen formation

Active yeast plays a crucial role in the formation of krausen during beer brewing. As the fermentation process begins, the active yeast cells metabolize the sugars in the wort and produce alcohol and carbon dioxide.

This production of carbon dioxide leads to the formation of a foamy layer on top of the beer known as krausen. The active yeast cells are responsible for creating this foam through their metabolic activity.

During fermentation, the active yeast cells consume sugars and produce alcohol as well as various flavor compounds that contribute to the overall character and quality of the beer. As these yeast cells multiply and metabolize, they release carbon dioxide gas into the beer.

The accumulation of carbon dioxide causes bubbles to form and rise to the surface, creating a thick layer of foam known as krausen.

The role of active yeast in krausen formation goes beyond just creating foam on top of the beer. The metabolic activity of yeast during this stage is vital for its health and viability throughout the fermentation process.

The presence of krausen indicates that the yeast is actively fermenting and converting sugars into alcohol, ensuring proper attenuation and flavor development in the final product.

Notably, understanding this role can help brewers manage fermentation more effectively by monitoring krausen height and adjusting temperature or nutrient levels if necessary.

By controlling krausen formation, brewers can optimize yeast performance, promote healthy fermentation, and ultimately achieve desired flavors and aromas in their beers.

Throughout history, brewers have recognized the significance of active yeast in krausen formation for producing high-quality beers. This understanding has been incorporated into traditional brewing techniques such as Bavarian beer purity laws which regulate ingredients used specifically during fermentation stages.

Additionally, traditional fermentation cellars were designed to accommodate krausen formation by providing ample headspace for foam expansion during fermentation.

Influence of unisomerized hop bitter compounds on krausen formation

In beer brewing, the formation of krausen is significantly influenced by unisomerized hop bitter compounds. These compounds, which are present in hops, play a crucial role in creating the foamy layer of krausen that develops on top of the fermenting beer.

The presence of these compounds contributes to the stability and height of krausen during the fermentation process.

Throughout the brewing process, active yeast interacts with these compounds and releases enzymes that break down the hop bitterness. This interaction leads to the production of chemical reactions that contribute to the formation and stability of krausen.

The characteristics and composition of unisomerized hop bitter compounds can have different effects on krausen formation, resulting in variations in the aroma, flavor, and appearance of the final beer product.

One unique aspect of unisomerized hop bitter compounds is their ability to enhance carbon dioxide production during fermentation. As yeast cells metabolize sugars in the wort, they generate carbon dioxide as a byproduct.

The presence of these compounds stimulates yeast activity and increases carbon dioxide production, leading to a more vigorous fermentation process and a higher krausen level.

The understanding of how unisomerized hop bitter compounds influence krausen formation is essential for brewers aiming to produce high-quality beer. The precise management of krausen height can affect both the flavor and aroma profiles, while also ensuring proper fermentation conditions.

By effectively managing these compounds, brewers can manipulate characteristics such as bitterness, aroma intensity, and foam stability to create unique and desired flavors that meet consumer expectations for quality craft beverages.

Understanding the Different Stages of Krausen

During the brewing process, understanding the different stages of krausen plays a crucial role in achieving the desired outcome. From the high krausen stage to the low krausen stage and finally the crashing krausen stage, each phase brings distinct characteristics to the beer.

By unraveling these stages, we can appreciate the fascinating transformations that occur and how they contribute to the overall quality and flavor profiles.

High krausen stage

During the high krausen stage, which occurs in the early fermentation process of beer brewing, the active yeast plays a significant role in creating a foamy layer known as krausen.

The presence of unisomerized hop bitter compounds also influences the formation of krausen.

- Active yeast is responsible for the formation of krausen during the high krausen stage.

- Krausen is created due to the influence of unisomerized hop bitter compounds.

- The high krausen stage is characterized by a thick and frothy layer of foam on top of the fermenting beer.

- This stage is crucial for metabolizing yeast cells and producing carbon dioxide, which contributes to the bubbling activity seen during fermentation.

Now, let’s delve into unique details pertaining to this stage. It’s important to note that managing krausen height becomes essential during this stage. Techniques can be employed to control or manipulate the height of krausen, ensuring optimal conditions for fermentation. Additionally, blow-off tubes can be used to prevent excessive pressure build-up and potential krausen blowouts that may occur during this vigorous fermentation phase.

Prepare for the beer to mellow out as we enter the low krausen stage, like a calm after the explosive yeast party.

Low krausen stage

The low krausen stage is an important phase in the fermentation process of beer brewing. It is characterized by a reduction in foaming and bubbling activity, as the foam or krausen on top of the fermenting beer begins to subside and settle down. This indicates a transition from the high krausen stage, where vigorous fermentation activity is observed.

During the low krausen stage, yeast cells start to settle at the bottom of the fermentation vessel. This settling of yeast cells contributes to the beer becoming clearer, as suspended particles begin to settle, leading to visual clarity. Additionally, carbonation levels stabilize during this stage, resulting in a more balanced flavor profile of the beer.

It is important to note that even during this stage, there is still active fermentation taking place, although at a slower pace compared to earlier stages. The settling of yeast cells and reduction in foam indicate that most of the primary fermentation has occurred, but secondary fermentation processes may still be ongoing.

A unique detail about the low krausen stage is that it sets the foundation for further maturation and conditioning of the beer. As yeast cells continue their metabolic activities, they contribute to the development of desired flavors and aromas in the beer.

Furthermore, proper management of krausen during brewing plays a crucial role in achieving consistent and high-quality beers. Brewers employ various techniques such as controlling krausen height and using blow-off tubes to prevent krausen blowouts, ensuring optimal fermentation conditions throughout all stages of krausen development.

Crashing krausen stage

The crashing krausen stage is a critical phase in the beer brewing process. It occurs after the high krausen stage and is characterized by the gradual settling and dissipation of the foam on top of the fermenting beer.

During this stage, the intense activity of yeast begins to subside, and the beer starts to clarify.

Here is a 6-step guide to understanding the crashing krausen stage:

- At this stage, the active yeast cells have consumed most of the fermentable sugars, resulting in a reduction in their metabolic activity.

- As a result, carbon dioxide production decreases significantly compared to the previous stages.

- The foam that formed during high krausen starts to collapse and settle as yeast cells fall out of suspension.

- This settling process aids in clarifying the beer by removing any remaining suspended solids and yeast cells.

- Temperature control during this stage is crucial as it helps facilitate yeast flocculation, which refers to yeast cells clumping together and then sinking to the bottom of the fermentation vessel.

- The length of this stage can vary depending on factors such as yeast strain, fermentation temperature, and desired flavor profile.

It’s important to note that during the crashing krausen stage, cold crashing or fining agents can be employed to further enhance beer clarity before packaging or transferring it to secondary fermentation vessels.

Significance of Krausen in Fermentation

Krausen, a crucial element in the fermentation process of beer, plays a significant role in metabolizing yeast cells and the production of carbon dioxide. Its presence during fermentation is essential for achieving the desired flavor and carbonation in the final product.

Understanding the importance and functions of krausen sheds light on the intricate process of brewing and helps brewers create high-quality, flavorful beers.

Krausen reflect yeast activity and health

Krausen plays a vital role in the process of metabolizing yeast cells during beer fermentation. The role of the active yeast in krausen formation aids in the breakdown and utilization of sugars, ultimately promoting the growth and multiplication of yeast cells.

This metabolic activity is crucial for achieving optimal fermentation and the desired flavor profile of the beer. Additionally, krausen also assists in maintaining a healthy yeast population by providing necessary nutrients for their survival and growth.

During the high krausen stage, when krausen is at its peak height, the metabolizing yeast cells are most active. They convert fermentable sugars into alcohol and carbon dioxide, producing characteristic flavors and aromas in the beer.

As krausen subsides into the low krausen stage, which is marked by a gradual reduction in foam volume, yeast cells continue to metabolize at a slower pace but remain an important contributor to flavor development.

As fermentation progresses to the crashing krausen stage, where foam dissipates completely, yeast cells undergo a more controlled metabolic process to complete fermentation. At this point, they clean up any undesirable compounds created during earlier stages and further develop nuanced flavors.

Pro Tip: To promote healthy yeast metabolism during krausen formation, it is recommended to provide proper oxygenation and nutrient conditions for yeast growth before pitching them into wort.

A so called “yeast starter culture”.This will enhance their ability to effectively metabolize sugars during fermentation.

During krausen, beer bubbles like a bottle of carbonated laughter, thanks to the yeasts’ fart-like expertise in producing carbon dioxide.

Production of carbon dioxide during krausen

During krausen, the fermentation process in beer brewing leads to the production of carbon dioxide (CO2). Active yeast plays a crucial role in this process, as it metabolizes the sugars present in the wort and produces both alcohol and CO2.

The CO2 generated cause krausen and contributes to the characteristic carbonation and effervescence of beer.

As the yeast cells consume the sugars, they produce not only alcohol but also CO2 as a byproduct. This release of CO2 creates pressure within the fermentation vessel, causing it to build up gradually.

The formation of krausen acts as an indicator of active fermentation and is characterized by a dense foamy layer on top of the fermenting beer. This layer consists mainly of yeast cells, hop compounds, proteins, and other substances.

The production of carbon dioxide during krausen has several important implications for beer brewing. Firstly, it helps to purge oxygen from the fermentation vessel, creating an anaerobic environment that is favorable for yeast activity and minimizing oxidation of the beer.

Additionally, the release of CO2 helps to drive off unwanted flavors or volatile compounds that can affect the taste and aroma of the final product.

In addition to its role in carbonation and flavor development, krausen also serves as a visual indicator for brewers during fermentation.

By observing changes in height or thickness of krausen over time, brewers can monitor the progress of fermentation and make adjustments if necessary. Furthermore, managing krausen height is essential to prevent overflows or blowouts during active fermentation.

Keep your krausen under control or risk being foamed out of brewing existence.

Managing Krausen During the Brewing Process

During the brewing process, one crucial aspect to manage is krausen. In this section, we’ll discuss effective techniques for controlling krausen height and preventing krausen blowouts using blow-off tubes. These methods ensure a smoother brewing experience and maintain the quality of the beer.

Let’s explore how brewers can tackle the challenges of krausen management with precision and expertise.

Techniques to control krausen height

To ensure optimum control over krausen height during the brewing process, several techniques can be employed. These techniques aim to prevent excessive foam formation and minimize the risk of blowouts.

One effective technique is the implementation of a controlled fermentation temperature. By maintaining a stable and lower temperature, the activity of the yeast can be regulated, resulting in a more controlled production of krausen.

Step-by-step guide to controlling krausen height:

- Fermentation Temperature Control: Maintain a stable and lower fermentation temperature to regulate yeast activity.

- Proper Pitching Rate: Ensure an appropriate amount of yeast is pitched into the wort to avoid excessive yeast growth and subsequent krausen formation.

- Use Anti-Foaming Agents: Add anti-foaming agents during the brewing process to help reduce foam formation and control krausen height.

- Vigorous Wort Aeration: Properly aerate the wort before pitching the yeast to promote healthy fermentation without excessive krausen buildup.

By following these techniques, brewers can effectively manage and control the height of krausen during fermentation, resulting in improved brewing efficiency and reduced risk of blowouts.

It is important to note that each step plays a significant role in controlling krausen height; however, additional factors such as choice of yeast strain and wort composition may also impact krausen formation.

Brewers should carefully consider these factors alongside implementing these techniques for optimal results in managing krausen levels during the brewing process.

No one wants a krausen catastrophe, so use blow-off tubes to keep your beer from exploding.

Use of blow-off tubes to prevent krausen blowouts

The use of blow-off tubes is an effective technique in preventing krausen blowouts during the beer brewing process.

Krausen blowouts can occur when the foam produced by the fermentation process exceeds the capacity of the fermenter, leading to messy and potentially dangerous situations. By utilizing blow-off tubes, brewers can safely redirect and control the excessive krausen foam.

To effectively prevent krausen blowouts using blow-off tubes, follow these six steps:

- Select a suitable blow-off tube: Choose a tube with an appropriate diameter and length to accommodate the level of krausen expected during fermentation.

- Attach the blow-off tube to a fermenter: Connect one end of the tube securely to a dedicated fitting on your fermenter or airlock system.

- Position the other end of the tube: Place the open end of the tube in a container filled with sanitized liquid, such as water or sanitizer solution. This allows for continuous gas release while preventing any potential contamination.

- Monitor and adjust: Regularly check and monitor the krausen level in your fermenter. If it reaches near or above capacity, adjust or replace your blow-off tube as necessary to prevent blockages and overflows.

- Ensure proper seal: Verify that all connections between your fermenter, airlock system, and blow-off tube are tightly sealed to maintain pressure control during fermentation.

- Clean and sanitize: After fermentation is complete, promptly clean and sanitize all components used in the blow-off system to prevent bacterial growth or contamination for future batches.

It is worth noting that while using blow-off tubes effectively prevents krausen blowouts, brewers should also consider factors such as temperature control and yeast strain selection to ensure optimal fermentation conditions.

Understanding how to avoid krausen blowouts is essential in maintaining a smooth brewing process and avoiding unnecessary messes and potential hazards that may arise from excessive foam buildup during fermentation. By implementing these techniques, brewers can better manage the krausen stage and improve overall brewing efficiency.

The foam on a beer may be fleeting, but the krausen’s impact on flavor and aroma lasts long after the glass is empty.

The Role of Krausen in Beer Quality

Krausen plays a vital role in ensuring the quality of beer, impacting both its flavor and aroma. Additionally, the presence of a consistent and uniform head of foam is of utmost importance.

Let’s explore the significance of krausen in beer production and how these factors contribute to the overall beer drinking experience.

Influence of krausen on beer flavor and aroma

In beer brewing, the formation of krausen plays a crucial role in influencing the flavor and aroma of the final product. Krausen refers to the foamy layer that forms on top of the fermenting beer during fermentation. It is formed due to the active yeast cells metabolizing sugars and producing carbon dioxide gas. This process not only helps in creating a uniform head of foam but also contributes to the release of aromatic compounds that enhance the overall flavor profile of the beer.

During the high krausen stage, which is typically observed within the first few days of fermentation, the krausen layer is at its peak height and activity. It is during this stage that significant ester production occurs, leading to fruity and floral aromas in the beer. The presence of volatiles released from hop bitter compounds also adds complexity to the aroma profile.

As fermentation progresses and reaches the low krausen stage, which usually occurs after about a week, the krausen layer starts to subside, resulting in a decrease in active yeast activity. However, important flavor compounds continue to be developed during this stage as residual yeast continues to metabolize byproducts produced earlier, such as diacetyl. This stage is essential for ensuring a clean and balanced flavor profile in the final beer.

In addition to its impact on flavor and aroma development, krausen also plays a vital role in promoting healthy yeast cell metabolism. The dense foam structure provides protection for yeast cells against potential contaminants present in the environment.

Furthermore, as carbon dioxide is released during krausen formation, it helps purge excess oxygen from the fermentation vessel, which is beneficial for maintaining optimal yeast performance throughout the brewing process.

To manage krausen effectively during brewing, various techniques can be employed. Controlling krausen height can be achieved by adjusting fermentation temperature or using specific yeast strains with desired flocculation characteristics.

Additionally, blow-off tubes can be used to prevent krausen blowouts, where excess foam can overflow from the fermenter and cause mess and potential loss of beer.

Traditional brewing techniques also recognize the significance of krausen. For example, Bavarian beer purity laws specify that only traditional ingredients must be used in brewing, including allowing the use of a portion of actively fermenting beer (krausen) for fermentation. This practice not only contributes to maintaining the authenticity of certain beer styles but also aids in achieving desired flavor profiles.

Importance of a uniform head of foam in beer

A uniform head of foam in beer is of utmost importance. It not only enhances the visual appeal of the beer but also entices and invites consumers.

This distinct and desirable aesthetic is associated with high-quality beer. In addition, the foam acts as a natural barrier, retaining the aroma and volatile compounds within the beer.

This ensures that the drinker can fully experience the intended flavors and aromas. Moreover, a uniform head of foam contributes to the mouthfeel of the beer, providing a creamy and smooth texture that enhances the overall drinking experience.

During the brewing process, krausen formation directly affects the development of a uniform head of foam. Krausen is formed by active yeast during fermentation and comprises yeast cells, hop compounds, proteins, and other components.

It is during this stage that carbon dioxide is produced and released by the yeast cells. Krausen plays a crucial role in creating and maintaining a stable head of foam on top of the beer. Various factors, such as yeast activity, hop bitter compounds, temperature control, and management techniques, influence the height and stability of krausen.

To achieve a uniform head of foam, brewers need to carefully manage krausen. Techniques such as controlling krausen height through proper pitching rates or using anti-foaming agents can assist in achieving desired results.

Another commonly employed method is the use of blow-off tubes to prevent excessive foaming during fermentation. By effectively managing krausen formation, brewers can ensure an appealing appearance with a consistent head of foam in their beers.

Traditional brewing techniques have long recognized the significance of krausen in achieving a uniform head of foam. Bavarian beer purity laws, for instance, have strict regulations regarding brewing ingredients and fermentation conditions.

These laws emphasize the importance of maintaining the quality and consistency of beer, including its appearance and foam characteristics. Furthermore, traditional fermentation cellars are designed to provide ideal conditions for krausen formation, enabling brewers to produce beers with a uniform head of foam that meets their high standards.

Traditional Techniques Involving Krausen

Traditional Techniques Involving Krausen: Explore how Bavarian beer purity laws and traditional fermentation cellars utilize krausen, adding depth and flavor to beer production.

Bavarian beer purity laws and krausen

Bavarian beer purity laws and krausen have a long-standing relationship that has shaped the brewing process for centuries. These laws, known as Reinheitsgebot, were put in place to regulate the production of Bavarian beer and maintain its quality. One important aspect of these laws is the utilization of krausen as a natural method for controlling fermentation.

Krausen plays a crucial role in the traditional brewing practices of Bavaria. It forms during fermentation as the yeast cells actively consume sugars, resulting in the release of carbon dioxide and alcohol.

The presence of krausen is a positive indication that fermentation is progressing smoothly, and the yeast is actively converting sugars into alcohol.

In the context of Bavarian beer purity laws, krausen serves as a key indicator of the beer’s quality and adherence to brewing standards. Brewers meticulously monitor the formation and development of krausen throughout the fermentation process to ensure that the beer meets the stringent requirements established by these laws.

As krausen forms and gradually subsides during different stages of fermentation, it undergoes changes that directly influence the flavor and aroma profiles of the final product. This highlights the importance of brewers effectively managing the height of krausen.

In accordance with Bavarian beer purity laws, maintaining a consistent head of foam, which is closely associated with krausen when pouring, significantly contributes to the overall sensory experience of enjoying a properly brewed Bavarian beer.

The relationship between Bavarian beer purity laws and krausen exemplifies how historical brewing practices have not only shaped quality standards but also influenced the sensory aspects associated with Bavarian beers. These laws continue to play a vital role in preserving traditional brewing techniques while ensuring a consistently delightful taste experience for beer enthusiasts worldwide.

Unleash the power of krausen in traditional fermentation cellars for the tastiest beer experience.

Traditional fermentation cellars and krausen

Traditional fermentation cellars and krausen have a long and storied history in the world of beer brewing. These cellars, which have been in use for centuries, play a vital role in the formation and management of krausen during the fermentation process.

The controlled temperature and humidity levels found in these traditional cellars create the perfect conditions for the krausen to develop, ultimately contributing to the overall quality and flavor of the beer.

Within these traditional fermentation cellars, brewers employ various techniques to ensure optimal krausen formation. One popular method is the use of open fermentation vessels, which allow for increased yeast activity and the interaction of the yeast with hop compounds.

By promoting this interaction, brewers can enhance the flavors and aromas present in the final product. Furthermore, brewers in these cellars often utilize special fermentation vessels or adjust the yeast pitching rate to control the height of the krausen, ensuring it remains within the desired range.

It is also important to note that traditional fermentation cellars serve a dual purpose: they are not only used for fermentation but also for the storage and aging of beer. The extended aging period in these cellars allows the krausen to gradually settle, further enhancing the flavor profile of the beer. Through this aging process, the beer becomes more refined and complex, offering a truly unique drinking experience.

One fascinating example of traditional fermentation cellars can be found in Bavaria. In this region, strict beer purity laws specify the ingredients that can be used in brewing. These laws state that only malted grains, hops, water, and yeast are permitted.

Because of these regulations, Bavarian breweries heavily rely on their fermentation cellars to cultivate and nurture the specific characteristics of krausen that are desired in German-style beers. It is through these traditional methods that exceptional Bavarian beers are created.

In conclusion, traditional fermentation cellars and krausen are essential components of the beer brewing process. From their important role in krausen formation to their use in beer aging and storage, these cellars contribute to the production of high-quality, flavorful beers.

Whether it’s through techniques like open fermentation or adherence to strict brewing laws, the tradition of fermentation cellars and krausen continues to shape and define the world of beer.

Conclusion

Krausen in beer plays a significant role in the fermentation process, serving as a foamy substance consisting of yeast, hops, and proteins. It acts as a sign that fermentation is active and contributes to the overall quality of the final product.

One of its primary functions is the release of carbon dioxide, which is trapped within the krausen, creating a protective layer of foam that prevents oxygen exposure. This protective barrier is crucial in maintaining the quality of the beer and preventing off-flavors and spoilage.

Additionally, krausen contributes to the sensory characteristics of the beer. As the yeast and hops release various compounds during fermentation, these compounds become trapped within the foam of the krausen, giving it a unique and distinct aroma and flavor.

Depending on the specific yeast strain and hop varieties used, these aromas and flavors can range from fruity and estery to spicy and herbal. As fermentation progresses and the krausen subsides, these aromatic and flavor compounds integrate into the beer, enhancing its overall complexity and depth.

Understanding the historical significance of krausen in beer provides insight into the long-standing tradition of brewing and its evolution over time. In the past, brewers utilized krausen as a natural carbonation method, using it to provide the necessary yeast and carbonation to a new batch of beer.

This method, known as krausening, ensured consistent carbonation levels and balanced flavors in the beer, without the need for added sugars or artificial carbonation techniques.

While modern brewing techniques have provided alternative methods for carbonation, krausen remains appreciated for its role in fermentation and flavor development. Today, it continues to be a vital sign of a healthy and active fermentation process, valued by both brewers and beer enthusiasts.

Key Takeaways:

- Krausen in beer refers to the foamy layer that forms on top of the fermenting beer or cider. It is important for brewers to understand krausen as it plays a crucial role in the fermentation process.

- Krausen formation is mainly influenced by active yeast and unisomerized hop bitter compounds. The interaction between these elements leads to the development of krausen during beer brewing.

- Understanding the different stages of krausen, such as high krausen, low krausen, and crashing krausen, helps brewers monitor and control the fermentation process more effectively.

- Krausen reflects multiple effects of fermentation, including metabolizing yeast cells and producing carbon dioxide, which is essential for carbonation in beer.

- Brewers can manage krausen during the brewing process by employing techniques to control krausen height and using blow-off tubes to prevent krausen blowouts, which can cause a messy and potentially dangerous situation.

- Krausen influences the flavor and aroma of beer, and a uniform head of foam is considered important for the overall quality of the beer.

- Traditional techniques involving krausen include Bavarian beer purity laws, which require the use of krausen to naturally carbonate beer, and the use of fermentation cellars, where krausen plays a crucial role in temperature control and fermentation stability.

FAQs

What does krausen indicate during fermentation?

Krausen indicates that fermentation is actively taking place in the beer. It is a visual sign that the yeast is converting sugars into alcohol and producing carbon dioxide.

Can krausen affect the taste of beer?

Krausen can contain intensely bitter compounds and other residues. While some brewers believe it adds flavor complexity, the material found in krausen is typically not reintroduced back into the beer as it can be bitter.

How can krausen blowouts be prevented?

To prevent krausen blowouts, where the foam pushes its way up through the airlock, a blow-off tube or an anti-foaming agent like FermCap-S can be used. A blow-off tube allows carbon dioxide to escape while preventing oxygen and bacteria from entering the fermenter.

What is the difference between low krausen and high krausen?

Low krausen refers to the early stages of fermentation when a thin layer of foam forms on the surface of the wort. High krausen is the peak stage of fermentation when the foamy layer becomes thicker and more unruly.