As a brewer and microbiologist with years of experience under my belt, I have often been asked the question about substrates for fermentation (yeast food, that is!). And This one is not different: So can you ferment high fructose corn syrup?

The short answer is yes, you can ferment high fructose corn syrup. But not on its own of course, there are certain factors to consider, such as water and additional nutrients, to ensure a successful fermentation.

In this post, I will dive into the process of fermenting high fructose corn syrup and the various factors that play a role in ensuring a successful outcome. So, grab your brewing equipment and let’s get started!

What is High Fructose Corn Syrup (HFCS)?

Before we jump into the fermentation process, let’s first understand what high fructose corn syrup is. High fructose corn syrup (HFCS) is a sweetener derived from corn starch.

It is commonly used in the food and beverage industry as a cheaper alternative to sugar, thanks to its high sweetness and low cost.

HFCS is made up of two simple sugars: fructose and glucose, which are naturally occurring in fruits and honey.

The ratio of fructose to glucose varies depending on the type of HFCS used. The most common types are HFCS-42, which contains 42% fructose and 58% glucose, and HFCS-55, which contains 55% fructose and 45% glucose.

Yeast Loves Sugar, But Treats Them Differently!

Yeast metabolism can vary depending on the type of sugar present in the fermentation process. Let’s examine the difference in yeast metabolism for various sugars commonly found in the fermentation of fruit juice (cider and wine), mead (honey), and mashed grains (beer).

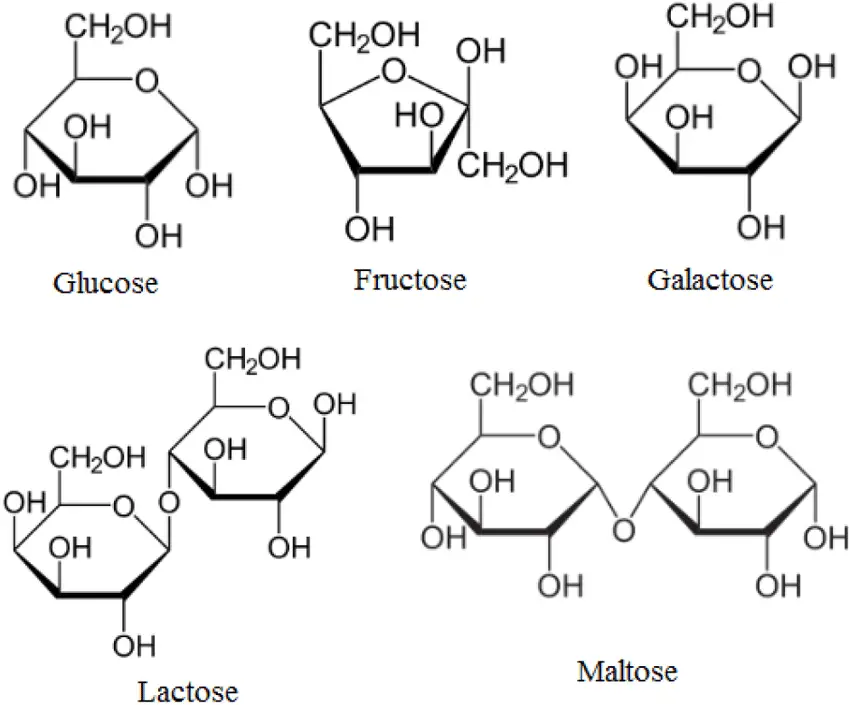

- Glucose: Glucose is a simple sugar that yeast can readily metabolize. Yeast cells convert glucose into ethanol and carbon dioxide through a process called alcoholic fermentation. Glucose is efficiently metabolized by yeast, and it is a common sugar found in fruit juice, honey, and mashed grains.

- Fructose: Fructose is another simple sugar commonly found in fruit juice. Yeast can metabolize fructose, but the efficiency is slightly lower compared to glucose. The fermentation of fructose produces ethanol and carbon dioxide, similar to glucose fermentation.

- Sucrose: Sucrose is a disaccharide composed of glucose and fructose molecules. Yeast cells must first break down sucrose into its component sugars using the enzyme invertase before they can metabolize it. Once broken down, yeast can metabolize glucose and fructose separately through their respective pathways. However, the metabolism of sucrose is slightly less efficient than that of glucose alone.

- Maltose: Maltose is a disaccharide formed from two glucose molecules. Yeast can efficiently metabolize maltose by producing the enzyme maltase, which breaks maltose into its glucose components. The glucose is then metabolized through the yeast’s glucose fermentation pathway. Maltose is commonly found in mashed grains and is an important sugar in beer production.

- Galactose: Galactose is a monosaccharide that yeast can metabolize, but it is not as efficient as glucose or maltose. Yeast cells convert galactose into ethanol and carbon dioxide through the galactose fermentation pathway. However, the rate of fermentation for galactose is slower compared to other sugars.

- Lactose: Lactose is a disaccharide consisting of glucose and galactose molecules. Yeast cells used in brewing cannot natively break down lactose and it is therefore often used as a non-fermentable sweetener in brewing.

In terms of efficiency, glucose and maltose are the most efficiently metabolized sugars by yeast. These sugars are readily broken down and utilized by yeast cells in the fermentation process. However, it’s important to note that the specific yeast strain being used and the fermentation conditions can also influence the overall efficiency of sugar metabolism.

The Fermentation Process

Fermentation is the process of converting sugars into alcohol and carbon dioxide through the action of yeast. In the case of fermenting high fructose corn syrup, the yeast consumes the glucose and fructose, producing ethanol and carbon dioxide as by-products.

To begin the fermentation process, you will need to mix the high fructose corn syrup with water and additional nutrients, as well as the yeast.

The water will help to dilute the syrup, making it easier for the yeast to ferment the sugars. The additional nutrients, such as yeast nutrient or yeast energizer, provide essential elements for the yeast to thrive and complete the fermentation process.

Choosing the Right Yeast

When it comes to fermenting high fructose corn syrup, the choice of yeast is crucial. You want to select a yeast strain that is capable of fermenting both glucose and fructose, as well as being able to tolerate the high sugar concentration present in the corn syrup.

Some popular yeast strains for fermenting high fructose corn syrup include champagne yeast, wine yeast, and certain strains of ale yeast. These yeasts are known for their ability to ferment a wide range of sugars and their high alcohol tolerance, making them ideal for this process.

The Role of Water in Fermentation

As mentioned earlier, water plays a significant role in the fermentation of high fructose corn syrup. The water serves to dilute the syrup, making it easier for the yeast to access and ferment the sugars present.

Without the addition of water, the high sugar concentration in the corn syrup could inhibit the yeast, leading to stuck fermentation or incomplete fermentation.

It is essential to use clean, filtered water to avoid introducing any unwanted bacteria or contaminants into the fermentation process.

The ratio of water to corn syrup will depend on the desired alcohol content and flavor profile of the final product.

A good starting point is a 4:1 ratio of water to syrup, and you can adjust from there based on your preferences.

Adding Nutrients for a Healthy Fermentation

In addition to water, it is important to add nutrients to the fermentation process to ensure the yeast has everything it needs to thrive and complete the fermentation process. The high fructose corn syrup lacks certain essential nutrients, such as nitrogen, which the yeast requires.

Yeast nutrient and yeast energizer are commonly used to provide these essential elements. Yeast nutrient typically contains a blend of inorganic nitrogen, organic nitrogen, and trace minerals, while yeast energizer contains additional components such as vitamin B and amino acids.

Adding these nutrients to the fermentation process will help ensure a healthy environment for the yeast and increase the likelihood of a successful fermentation.

Monitoring the Fermentation Process

As with any fermentation, it is essential to monitor the progress of the high fructose corn syrup fermentation. This includes taking regular gravity readings using a hydrometer or refractometer to track the sugar consumption by the yeast and the production of alcohol.

You should also pay attention to the fermentation temperature, as this can have a significant impact on the yeast’s activity and the final flavor profile of the product. Most yeast strains will have an ideal temperature range for fermentation, which can typically be found on the yeast packaging or manufacturer’s website.

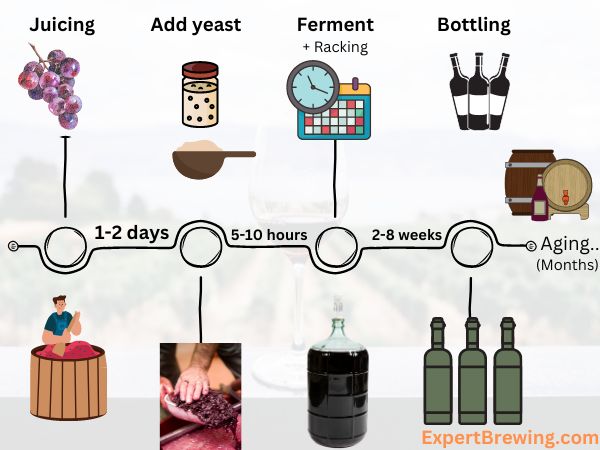

The Role of Time in Fermentation

The length of time required for fermenting high fructose corn syrup will depend on several factors, such as the yeast strain, temperature, and the initial sugar concentration in the syrup. Generally, fermentation can take anywhere from a few days to several weeks.

It is important to be patient and allow the yeast to complete the fermentation process. Rushing the process or bottling the product too soon can result in off-flavors or even bottle bombs due to residual sugar being fermented in the bottle.

Finishing and Bottling the Fermented Product

Once the fermentation process is complete, it is time to finish and bottle the fermented high fructose corn syrup product. This may involve additional steps such as clarifying the product, aging it to improve the flavor profile, or carbonating it if desired.

After completing these steps, the fermented product can be bottled and stored for consumption. Remember to sanitize all bottling equipment and use proper storage techniques to ensure the quality and safety of your final product.

In Conclusion: Fermenting High Fructose Corn Syrup

In conclusion, yes, high fructose corn syrup can be fermented, but it requires the addition of water and essential nutrients for a successful fermentation. To summarize, here are ten key facts about fermenting high fructose corn syrup:

1. High fructose corn syrup is a sweetener derived from corn starch, composed of glucose and fructose.

2. Fermentation is the process of converting sugars into alcohol and carbon dioxide through the action of yeast.

3. Water is crucial for diluting the corn syrup and making it more accessible for the yeast to ferment.

4. Additional nutrients, such as yeast nutrient and yeast energizer, are necessary to provide the yeast with essential elements.

5. Choose a yeast strain that can ferment both glucose and fructose and has a high alcohol tolerance.

6. Monitor the fermentation process, including gravity readings and temperature, for a successful outcome.

7. The length of time required for fermentation can vary depending on several factors, such as yeast strain and temperature.

8. Be patient and allow the yeast to complete the fermentation process before bottling.

9. Finishing and bottling the fermented product may involve additional steps, such as clarifying, aging, or carbonating.

10. Proper sanitization and storage techniques are essential for ensuring the quality and safety of the final product.

So, while fermenting high fructose corn syrup may be slightly more involved than fermenting simple sugars like table sugar, it is entirely possible with the right approach and attention to detail. Happy fermenting!

FAQs

Does high fructose corn syrup dissolve in water?

Yes, high fructose corn syrup dissolves in water.

How long does it take to make high fructose corn syrup?

It takes about 45 minutes to make high fructose corn syrup.

How is corn syrup made in a factory?

Corn syrup is made in a factory by first milling corn kernels to extract the starch. The starch is then mixed with water and enzymes to break it down into glucose. This glucose solution is then filtered and purified to remove impurities and color. Finally, the syrup is evaporated to the desired concentration and packaged for distribution.

Is corn syrup made from corn stalks?

No, corn syrup is made from the kernels of corn, not the stalks.

What does fructose do to water?

Fructose dissolves in water and does make a thick solution.

How much water does it take to make high fructose corn syrup?

It takes about 3.1 gallons of water to make 1 pound of high fructose corn syrup.