Have you ever wondered what diacetyl rest is in beer brewing and why it is so important?

Diacetyl, a compound that can affect the flavor of beer, needs to be carefully managed during the brewing process. In order to reduce it, brewers perform a so-called “diacetyl rest” after fermentation is completed.

We will explore what diacetyl is, how it affects beer, the ideal temperature for diacetyl rest, when to perform diacetyl rest, and how to do it successfully.

We will also discuss the risks of skipping diacetyl rest and provide tips for a successful diacetyl rest process.

Stay tuned to learn all about diacetyl rest in beer brewing!

What Is Diacetyl Rest in Beer Brewing?

Diacetyl rest in beer brewing is a crucial process that involves a resting period to reduce diacetyl levels and enhance the beer’s flavor profile.

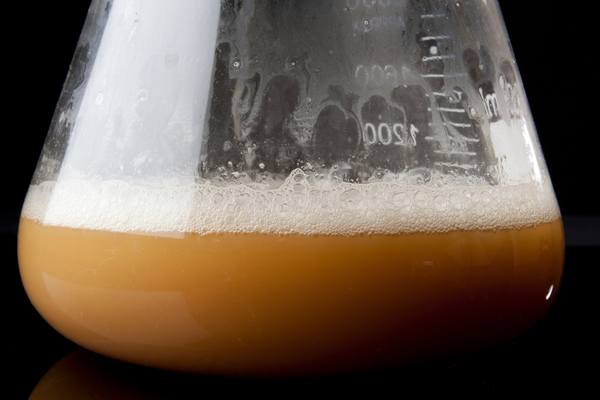

During fermentation, yeast produces diacetyl, which can impart a buttery or butterscotch flavor to the beer if not managed properly. By allowing the beer to rest at slightly higher temperatures post-fermentation, typically between 60-70°F for a few days, the yeast can clean up any remaining diacetyl in the beer.

This process is essential for lagers and some ales to ensure a clean and crisp finish, improving the overall quality and drinkability of the final product.

What Is Diacetyl and How Does It Affect Beer?

Diacetyl is a chemical compound that can impart a buttery flavor to beer, produced as a yeast byproduct during fermentation.

.jpg)

During the fermentation process, diacetyl is formed when certain yeast strains metabolize alpha-acetolactate, which is a precursor compound. This conversion of alpha-acetolactate to diacetyl can happen during the primary fermentation phase.

If not properly managed, diacetyl levels can rise, leading to undesirable buttery off-flavors in the beer. The presence of diacetyl is often more noticeable in lager-style beers due to the lower fermentation temperatures, which can slow down the reabsorption or reduction of diacetyl by the yeast.

Brewers need to carefully monitor the levels of diacetyl in the beer to ensure a clean and balanced flavor profile.

Why Is Diacetyl Rest Important in Beer Brewing?

Diacetyl rest is essential in beer brewing to ensure a clean beer with a well-developed flavor profile, avoiding off-flavors and maintaining quality control.

During fermentation, yeast produces diacetyl, which, if not properly controlled, can lead to buttery or butterscotch off-flavors in the final beer. The diacetyl rest is a crucial step where the beer is allowed to rest at a slightly elevated temperature after primary fermentation to encourage the yeast to reabsorb and reduce diacetyl levels. This process plays a significant role in ensuring that the beer reaches its full potential in terms of flavor and quality.

Quality control measures, such as regular tasting panels and sensory analysis, help brewers detect any off-flavors early on, allowing for timely adjustments to be made in the brewing process.

What Is the Ideal Temperature for Diacetyl Rest?

The ideal temperature for diacetyl rest varies but typically involves a slight increase in temperature post-fermentation for lagering or maturation at a controlled cellar temperature.

Maintaining proper temperature control is crucial during this phase as it allows for the yeast to continue its activity without being too stressed or becoming inactive. Lagering conditions require a steady and gradual decrease in temperature to promote clarity and smooth flavor development. Cellar temperatures should ideally be kept stable to ensure the desired outcomes of the diacetyl rest process.

Fluctuations in temperature can impact the overall quality of the beer, so monitoring and adjusting temperatures diligently is key to achieving optimal results.

When Should Diacetyl Rest Be Performed?

Diacetyl rest should be performed towards the end of fermentation or during secondary fermentation to facilitate diacetyl reduction and create a clean beer profile.

This crucial stage in the brewing process typically occurs when the yeast is still active but approaching the end of its fermentation activity. Allowing the beer to rest at a slightly elevated temperature, usually around 65-70°F, for a specified period is essential for the yeast to absorb and metabolize any diacetyl present. The ideal timing for a diacetyl rest can vary depending on the particular yeast strain and beer style, but typically lasts around 1-3 days. This resting period is instrumental in ensuring that diacetyl levels are reduced, resulting in a smoother, better-tasting final product.

What Are the Signs That Diacetyl Rest Is Needed?

Signs that diacetyl rest is needed include the detection of diacetyl syndrome through sensory evaluation, indicating the presence of buttery off-flavors in the beer.

This syndrome is often recognized by a slick, oily mouthfeel coupled with a pervasive butter-like aroma. Another key indicator is the lingering aftertaste that leaves a butterscotch-like sensation on the palate. Brewers can also look out for an increase in the slickness or oiliness of the beer during sensory analysis, as this could be a clear sign that diacetyl rest is required. By honing in on these sensory cues, brewers can take proactive measures to address any diacetyl-related off-flavors and ensure a clean, high-quality final product.

What Are the Risks of Skipping Diacetyl Rest?

Skipping diacetyl rest can lead to the persistence of off-flavors in the beer, compromising quality control and resulting in an undesirable flavor profile.

During the fermentation process, yeast produces diacetyl, a compound that imparts buttery or butterscotch-like flavors to the beer. Without a proper diacetyl rest, these off-flavors may not have the chance to dissipate, leading to a final product that falls short of the intended taste.

Quality control measures in beer brewing are crucial to ensure that each batch meets the desired standards. Neglecting the diacetyl rest step can throw off this balance, resulting in inconsistency and potentially disappointing outcomes for both brewers and consumers alike.

How to Perform Diacetyl Rest (Step by step)?

Performing diacetyl rest involves specific steps such as raising the temperature, monitoring diacetyl levels, conducting a diacetyl test, and then lowering the temperature for continued fermentation.

- During the diacetyl rest process, the key is to gradually increase the temperature in the fermenter to around 65-70°F (18-21°C) to encourage the yeast to metabolize any remaining diacetyl. This temperature adjustment is crucial for the reduction of buttery off-flavors in the beer.

- After reaching the desired temperature, it is essential to let the beer sit for a period of time, typically a couple of days, to allow the yeast to do its work effectively. During this time, some brewers may also conduct a diacetyl test to ensure that the levels have decreased to acceptable thresholds.

- Once the diacetyl levels have been confirmed to be within range, the next step is to slowly lower the temperature back to the fermentation range, usually between 50-55°F (10-13°C). This cooling phase helps the yeast settle and clean up any byproducts, contributing to a smoother and cleaner final beer product.

The fermenter plays a critical role during this cooling phase as it provides the controlled environment needed for the yeast to complete its final tasks before the beer is ready for packaging or conditioning.

Step 1: Raise the Temperature

- The first step in diacetyl rest is to raise the temperature gradually to promote yeast health and prevent autolysis, facilitating the reduction of diacetyl levels.

- By gradually increasing the temperature, yeast metabolism is boosted, leading to improved yeast health and activity. This process encourages yeast to clean up any remaining diacetyl, reducing the risk of off-flavors. A carefully controlled temperature increase helps prevent autolysis, a phenomenon where yeast cells break down and release undesirable compounds that can impact the beer’s flavor and aroma negatively.

- Taking these steps ensures a smoother, cleaner fermentation process and enhances the overall quality of the final beer product.

Step 2: Monitor the Diacetyl Levels

Monitoring diacetyl levels involves tracking volatile diacetyl compounds (VDKs) and diacetyl precursors to assess the progress of diacetyl reduction during the resting period.

VDKs are crucial indicators in this process as they represent the compounds responsible for the buttery or butterscotch off-flavors that can develop in beer if diacetyl levels are not adequately controlled.

By monitoring the levels of VDKs present in the beer, brewers can gauge the effectiveness of the diacetyl rest and determine if additional time is needed for the yeast to metabolize diacetyl precursors.

Understanding the relationship between VDKs and diacetyl precursors is essential for ensuring the final product meets quality standards and delivers a smooth, clean taste.

Step 3: Perform a Diacetyl Test

Conducting a diacetyl test, including forced diacetyl testing and VDK assessments, is essential to verify the success of diacetyl rest and ensure the reduction of buttery off-flavors.

- Forced diacetyl testing involves increasing the temperature of the beer sample to accelerate the diacetyl reduction process.

- During this test, the presence of diacetyl in the sample is monitored over a specific period.

VDK assessments focus on evaluating other volatile compounds such as pentanedione. By conducting these assessments, brewers can confirm the elimination of buttery off-flavors, ensuring that the final product meets quality standards and provides a pleasant drinking experience for consumers.

Step 4: Lower the Temperature

Lowering the temperature post-diactyl rest facilitates maturation and cold conditioning, further enhancing the beer’s flavor profile and promoting clarity.

During this phase, the beer is given time to undergo chemical reactions that help smooth out any harsh flavors and aromas, resulting in a more balanced and refined beverage. Cold conditioning also plays a crucial role in dropping out unwanted haze-causing proteins and yeast, leading to a crystal-clear appearance.

By slowing down the fermentation and aging process, the beer can develop complex flavors and aromas, contributing to a richer drinking experience for enthusiasts.

Step 5: Continue Fermentation

After diacetyl rest, allowing the fermentation process to continue assists in the mitigation of diacetyl byproducts through enzymatic activity and yeast metabolism.

During this extended fermentation period, enzymes produced by the yeast further break down diacetyl into compounds that are less pronounced in flavor and aroma, contributing to a smoother finish in the final product. The yeast’s metabolic pathways actively work to metabolize other undesirable compounds, such as acetaldehyde, enhancing the overall quality and complexity of the beer. This continued fermentation post diacetyl rest plays a crucial role in achieving a well-balanced and refined taste profile.

How Long Should Diacetyl Rest Last?

The duration of diacetyl rest can vary but typically lasts a few days to a week, with sensory evaluation guiding the decision on when to conclude the resting period.

During this crucial phase in beer brewing, factors such as the yeast strain used, fermentation temperature, and specific gravity play significant roles in determining the ideal length of the rest.

Yeast strains vary in their ability to reabsorb diacetyl, and higher fermentation temperatures can accelerate this process, shortening the required resting time.

Sensory evaluation, including taste and aroma assessments, is indispensable in detecting the presence of diacetyl and its levels, ensuring that the beer reaches optimal flavor profiles before moving to the next stage of production.

What Are Some Tips for Successful Diacetyl Rest?

To ensure a successful diacetyl rest, consider tips such as proper yeast propagation, effective wort oxygenation, and maintaining optimal temperature control throughout the process.

- When it comes to yeast propagation, starting with a healthy yeast population is crucial. Begin by using fresh yeast and follow recommended procedures for propagation to ensure robust yeast cells ready to ferment.

- Oxygenating the wort adequately before pitching the yeast can significantly impact fermentation. Proper aeration promotes yeast health and metabolism, aiding in the reduction of off-flavors like diacetyl.

- Consistent temperature control is equally vital; fluctuations can lead to stressed yeast and unwanted flavors. Utilize temperature-controlled fermentation chambers or systems to maintain a steady environment for optimal results.

What Are Some Common Mistakes in Diacetyl Rest?

Common mistakes in diacetyl rest include issues related to yeast viability, the presence of sulphur compounds, and inadequate temperature management, leading to off-flavors and quality issues.

When yeast viability is compromised during diacetyl rest, it can result in incomplete fermentation and an increased risk of off-flavors such as diacetyl remaining in the beer. Insufficient temperature control during this critical stage may lead to the production of unwanted sulfur compounds, contributing to off-aromas and impacting the overall beer quality.

Maintaining proper temperature levels not only aids in reducing diacetyl levels but also ensures that yeast activity remains optimal for the desired flavor profile in the final product.

Frequently Asked Questions

What is a diacetyl rest in beer brewing?

A diacetyl rest is a process in beer brewing where the temperature of the beer is raised towards the end of fermentation in order to reduce the presence of diacetyl, a byproduct of fermentation that can create an undesirable buttery or butterscotch flavor in beer.

Why is a diacetyl rest necessary in beer brewing?

A diacetyl rest is necessary to ensure that the beer has a clean and desirable flavor profile. Diacetyl can be produced during fermentation and if not taken care of, it can leave a negative taste in the finished beer. A diacetyl rest helps to reduce and eliminate this off-flavor.

When should I perform a diacetyl rest in my beer brewing process?

A diacetyl rest should be performed towards the end of fermentation, typically when the beer is about 75-80% of the way through fermentation. This usually occurs after the main fermentation stage is complete and the yeast is starting to settle at the bottom of the fermenter.

How long should a diacetyl rest last?

The length of a diacetyl rest can vary depending on the beer style and temperature. On average, it lasts for about 1-3 days, but it can be longer for lagers or if the temperature is lower. It’s important to monitor the beer and perform a diacetyl taste test to determine when the rest is complete.

What is the ideal temperature for a diacetyl rest?

The ideal temperature for a diacetyl rest is usually around 65-70°F (18-21°C). However, this can vary depending on the type of yeast and beer style being brewed. It’s important to follow the specific instructions for the yeast strain being used to ensure a successful diacetyl rest.

Do I need to perform a diacetyl rest for all beer styles?

No, not all beer styles require a diacetyl rest. Some strains of yeast are known for producing very low levels of diacetyl and some beer styles, such as Belgian ales, can actually benefit from a small amount of diacetyl flavor. It’s important to research the specific yeast and beer style being used to determine if a diacetyl rest is necessary.

Leave a Reply

You must be logged in to post a comment.