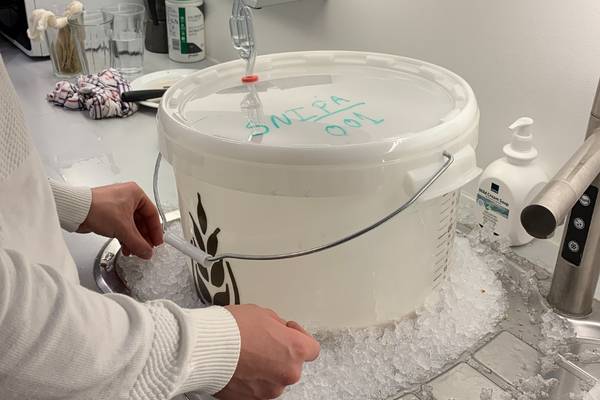

Cold crashing is a technique used by homebrewers and professional brewers alike to clarify beer before packaging.

The process involves rapidly chilling the fermented beer to near freezing temperatures (typically around 32-40°F or 0-4°C) for a short period (usually 24-72 hours).

This rapid temperature drop encourages yeast, proteins, and other particulates to flocculate and settle out of suspension, resulting in a clearer, cleaner-tasting beer.

Why should we worry about oxidation?

Oxidation is a chemical reaction that occurs when beer comes into contact with oxygen. While small amounts of oxygen are necessary for proper fermentation, excessive exposure can lead to off-flavors and a shorter shelf life for the finished product. Oxidation can cause stale, cardboard-like flavors, a decrease in hop aroma and bitterness, and a darkening of the beer’s color.

How does cold crashing cause oxidation?

The primary culprit for oxidation during cold crashing is the temperature change itself.

As the temperature of the beer decreases, the solubility of gases (including oxygen) in the liquid increases.

This means that any oxygen present in the headspace of the fermenter is more likely to dissolve into the beer when it is cold crashed.

Additionally, the act of cold crashing can cause a vacuum effect in the fermenter.

As the temperature drops, the air in the headspace contracts, which can draw oxygen into the fermenter through airlocks or other openings.

This introduces even more oxygen into the beer, increasing the risk of oxidation.

How to minimize oxidation during cold crashing

Thankfully, there are several steps homebrewers can take to minimize the risk of oxidation during cold crashing:

1. Limit headspace: The less headspace you have in your fermenter, the less oxygen is available to dissolve into your beer. Using a fermenter that is appropriately sized for your batch or transferring to a secondary fermenter with less headspace can help minimize this risk.

2. Purge with CO₂: Before cold crashing, purge the headspace of your fermenter with CO₂ to displace any oxygen. This can be done with a CO₂ tank and regulator or by using a CO₂-producing method such as dry ice.

3. Use an airlock with a one-way valve: Using an airlock with a one-way valve or a specialized cold crashing device can help prevent oxygen from being sucked back into the fermenter during the vacuum effect.

4. Seal the fermenter: Ensure that your fermenter is properly sealed and that there are no leaks where oxygen can enter.

5. Shorten the cold crashing duration: The longer the beer is exposed to cold temperatures, the more opportunity there is for oxidation to occur. Limiting the duration of cold crashing can help minimize this risk.

The impact of oxidation on different beer styles

The susceptibility of different beer styles to oxidation varies. Hop-forward beers, such as IPAs and pale ales, are particularly sensitive to oxidation, as it can significantly reduce the hop aroma and bitterness that defines these styles. Darker, maltier beers, such as stouts and porters, are generally more resistant to oxidation, although they can still develop stale flavors if exposed to excessive oxygen.

Balancing the benefits and risks of cold crashing

Cold crashing offers many benefits, such as improved clarity, cleaner flavor profiles, and reduced sediment in the finished product. However, it also carries a risk of oxidation. As a homebrewer, you must weigh the advantages against the potential downsides and decide whether cold crashing is worth it for your particular beer.

Alternative methods to achieve clarity

If you’re concerned about the risk of oxidation during cold crashing, there are alternative methods to achieve clarity in your beer:

1. Time: Allowing your beer to age and condition for an extended period can encourage the natural settling of particulates.

2. Fining agents: Adding fining agents, such as gelatin, isinglass, or biofine clear, can help to promote flocculation and sedimentation.

3. Filtering: Physically filtering your beer through a filtration system can remove particulates and improve clarity.

Conclusion

In conclusion, cold crashing does cause oxidation, but the extent and impact of oxidation can be managed with proper precautions. To minimize the risk of oxidation during cold crashing, consider the following:

1. Limit headspace in your fermenter.

2. Purge with CO₂ before cold crashing.

3. Use an airlock with a one-way valve.

4. Seal the fermenter properly.

5. Shorten the cold crashing duration.

6. Be aware of the impact of oxidation on different beer styles.

7. Balance the benefits and risks of cold crashing for your specific beer.

8. Consider alternative methods to achieve clarity if the risk of oxidation is too high.

By taking these measures, you can enjoy the benefits of cold crashing while minimizing the risk of oxidation, ensuring that your beer remains fresh and flavorful.

FAQs

Is cold crashing necessary?

Cold crashing is not necessary, but it can be a useful technique for improving the clarity and flavor of certain types of beer. It involves lowering the temperature of the beer to near-freezing levels for a period of time, which causes suspended particles to settle to the bottom of the fermenter. This can result in a clearer beer with less sediment and a crisper taste. However, not all beer styles benefit from cold crashing, and some brewers prefer to skip this step altogether. Ultimately, whether or not to cold crash is a matter of personal preference and the specific requirements of the beer being brewed.

What does cold crashing mead do?

Cold crashing mead is a process that involves lowering the temperature of the mead to near-freezing temperatures in order to encourage yeast and other sediment to settle to the bottom of the container. This results in a clearer and more stable mead with less sediment and haze.

Does cold crashing affect carbonation?

Cold crashing can affect carbonation by causing dissolved CO2 to come out of solution and form bubbles, which can lead to a loss of carbonation. However, if done correctly, cold crashing can help to clarify the beer and improve its overall quality. It is important to carefully control the temperature and duration of the cold crash to minimize any negative effects on carbonation.

Do you need to cold crash cider?

Cold crashing cider is not necessary but it can improve the clarity of the final product. It involves cooling the cider to near freezing temperatures for a few days to allow any suspended particles to settle to the bottom. However, some people prefer the natural cloudiness of unfiltered cider and choose not to cold crash.

Does temperature affect carbonation in beer?

Yes, temperature does affect carbonation in beer. Carbon dioxide is more soluble in colder liquids, meaning that colder beer will hold more carbon dioxide in solution, resulting in higher carbonation levels. Conversely, warmer beer will release carbon dioxide, resulting in lower carbonation levels. Therefore, it is important to store and serve beer at the appropriate temperature to achieve the desired level of carbonation.

What does cold crashing do?

Cold crashing is a process used in brewing where the temperature of the beer is lowered rapidly to near-freezing temperatures to encourage yeast and other particles to settle to the bottom of the fermentation vessel. This results in clearer beer with less sediment and a smoother taste.