You’ve probably experienced it: the unexpected buttery taste in your freshly brewed beer, an ABV that doesn’t quite align with your calculations, or even that dreaded overpressurization resulting in a messy bottle eruption.

Welcome to the world of “Hop Creep”, the uninvited guest in the brewing process. It’s not a game, nor is it the name of an elusive character from a mystery novel. But it can be equally enigmatic and surprising, especially if you aren’t familiar with how to handle it.

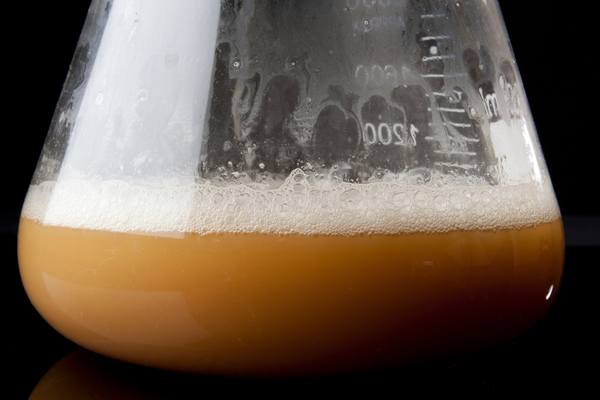

In essence, Hop Creep refers to the overattenuation of dry-hopped beer, leading to unwanted secondary fermentation which can alter the final gravity, introduce a diacetyl surge, and adjust the alcohol and CO2 content.

Understanding the Origin of Hop Creep

The phenomenon of Hop Creep has historical roots. Surprisingly, the first study on it was published way back in 1893. The brewing community had momentarily pushed it to the backdrop until the rise of dry-hopped IPAs in the mid-2010s.

Today’s research aligns with ancient brewing wisdom: the re-fermentation appears to happen when enzymes in hops, specifically diastase, interact with unfermentable carbs amidst active yeast.

To provide more clarity: hops carry starch-degrading enzymes called amylolytic enzymes. These enzymes play a crucial role in converting non-fermentable dextrins into fermentable sugars.

When you’re boiling your brew, these enzymes usually become inactive. However, when introduced to an unpasteurized, cold beer, they might trigger a secondary fermentation process, especially if there’s active yeast in suspension.

Are All Hops Susceptible to Creep?

This is a pivotal question, isn’t it? After all, if certain hop varieties are more prone to this phenomenon, one could simply avoid them.

While it’s true that some hops might show greater activity towards Hop Creep than others, experiments have shed light on an intricate pattern.

While Amarillo® and Cascade might alter the gravity and alcohol levels more than hops like Simcoe®, Centennial, and Citra®, many variables such as hop genetics, plant maturity, farming conditions, and post-harvest processing play an equally significant role.

Tactics to Keep Hop Creep in Check

It might sound like a brewing nightmare, but fear not, fellow brew enthusiast! There are several strategies to monitor, reduce, and control Hop Creep:

- Consistent Monitoring: Regularly measure the alcohol and specific gravity of your beer. This can be an indicator of overattenuation.

- Recipe Refinement: Draft recipes for a higher-fermentation wort or intentionally underattenuate the beer.

- Control Hop Contact: Evidence suggests that the intensity of hop aroma remains consistent whether dry-hopped for six hours or four days. Reducing the dry-hop time might not just reduce the risk of Hop Creep but can also give your beer a more fruity aromatic character.

- Temperature Play: Using temperature as a tool can be an asset. For example, dry hopping at cooler temperatures (around 50°F) and doing it quicker can significantly reduce the chances of Hop Creep.

As Scott Janish points out in his 2021 paper, the cooler dry-hopping method has a commendable track record. It’s an approach I’ve leaned on many times and it has seldom failed me.

Closing Thoughts on the Intricacies of Hop Creep

Hop Creep, while intricate and influenced by a myriad of factors, is not undefeatable. By maintaining rigorous quality checks, consistently monitoring parameters such as pH, gravity, and VDK counts, and being proactive in our brewing approaches, we can harness this phenomenon to our advantage or at least keep it at bay.

To wrap up, here are ten key takeaways on Hop Creep:

- Hop Creep results in unexpected secondary fermentation.

- It can introduce a diacetyl spike, altering flavor.

- It’s been known since 1893.

- Hop Creep is influenced by diastase enzymes in hops.

- Not all hops contribute equally to this phenomenon.

- Temperature control can mitigate its effects.

- Reduced dry-hop times can help.

- Hop Creep is affected by hop genetics and farming conditions.

- Consistent monitoring and quality checks are paramount.

- It can be managed with strategic brewing techniques.

From my own brewing journey, I’ve encountered and tackled Hop Creep multiple times. It’s a fascinating challenge, teaching us to be adaptive and meticulous in our brewing endeavors. Always remember, brewing is as much a science as it is an art. So, embrace the challenges and turn them into opportunities for crafting even better beers!

FAQs on Hop Creep

1. How do I identify if my beer has been affected by Hop Creep?

Typically, the symptoms of Hop Creep can range from an unexpected buttery flavor (due to the diacetyl spike) to increased alcohol content (higher than your initial calculation). Physically, you might notice overpressurization in bottled beers, which could lead to bottle caps popping off or, in extreme cases, exploding cans.

2. Does Hop Creep impact the shelf life of my beer?

Yes, it can. Since Hop Creep can result in overattenuation and production of diacetyl, beers affected by it can develop off-flavors over time. Furthermore, the overpressurization caused by Hop Creep can lead to compromised packaging integrity, which might shorten the beer’s shelf life.

3. Will reducing the quantity of hops in my recipe help in avoiding Hop Creep?

Not necessarily. While the amount of hops can influence the severity of Hop Creep, it’s more about the timing of hop addition and the specific hops’ enzymatic activity. For instance, adding some hops during the whirlpool pre-fermentation phase can reduce the risk.

4. I’ve heard of beers being pasteurized to avoid Hop Creep. Is this effective?

Yes, pasteurizing your beer can be an effective method to tackle Hop Creep. Pasteurization deactivates the amylolytic enzymes in hops, preventing them from breaking down dextrins into fermentable sugars. This can halt any potential secondary fermentation due to Hop Creep.

5. Can commercial breweries use any specialized equipment to combat Hop Creep?

Indeed, commercial breweries have access to specialized equipment and techniques to manage and reduce Hop Creep. Filtration systems, for instance, can help in removing the residual yeast, thereby reducing the chances of secondary fermentation. Additionally, implementing an unbroken cold-chain distribution system ensures that the beer remains at optimal temperatures, further minimizing the risk.

-recipe.jpg)