Secondary fermentation is a crucial step in the brewing process that often gets overlooked. It refers to the period of fermentation after the initial primary fermentation but before the beer is ready for consumption.

This secondary fermentation is a term for when the brewer transfers the brew after primary fermentation. Secondary fermentation allows for further flavor development, maturation, and clarification of the beer, cider, mead or wine.

In this blog post, we will explore the ins and outs of secondary fermentation in brewing and its significance in creating a high-quality, delicious brew.

What is secondary fermentation in brewing?

Secondary fermentation is a crucial process in brewing that takes place after the primary fermentation. It involves transferring the beer from the primary fermenter to a secondary vessel, such as a carboy or oak barrel, for further maturation.

The purpose of secondary fermentation is to clarify the beer, improve its flavor profile, and allow any remaining yeast to settle. During this stage, any sediments and unwanted flavors from the primary fermentation can be removed, resulting in a smoother and more refined beer.

Additionally, extended aging during secondary fermentation can enhance the beer’s clarity and create a cleaner taste. It is important to note that not all beers require a secondary fermentation, and the decision to perform this step depends on the style of beer being brewed and the desired outcome.

The purpose and benefits of secondary fermentation

The purpose of secondary fermentation in brewing is to further enhance and refine the flavor profile of the beer. It allows for the development of more complex flavors, as well as the reduction of off-flavors.

This process also helps improve the clarity and appearance of the beer and can contribute to its overall stability and shelf life.

Some of the key benefits of secondary fermentation include:

- Flavor Enhancement: Secondary fermentation allows for the continued fermentation of residual sugars and the production or addition of additional flavor compounds, resulting in a more well-rounded and balanced beer.

- Clarification: During secondary fermentation, the beer has the opportunity to settle and clarify further, as any remaining particles and sediment can settle to the bottom of the fermenter.

- Reduction of Off-Flavors: Secondary fermentation can help reduce off-flavors caused by certain compounds, such as diacetyl, by allowing the yeast to metabolize these compounds.

- Conditioning: The prolonged contact with yeast and any additional conditioning agents during secondary fermentation can contribute to a smoother and more refined beer.

- Experimentation: Secondary fermentation provides an opportunity for brewers to experiment with different flavors, such as adding fruit, spices, or other adjuncts to the beer during this stage.

- A final stabilization: Secondary fermentation also ensures that the yeast has finished eating all the accessible sugars, which makes the calculations for priming when bottle carbonating much easier!

It’s important to note that not all beer styles require or benefit from secondary fermentation. Some styles, like hop-forward beers, are often best consumed fresh and may not benefit from the extended aging process that secondary fermentation entails.

Overall, secondary fermentation offers brewers an additional tool for enhancing the quality and complexity of their beers, but it’s important to understand the specific requirements and considerations for each style before deciding to incorporate this step in the brewing process.

II. The Fermentation Process

Overview of primary fermentation

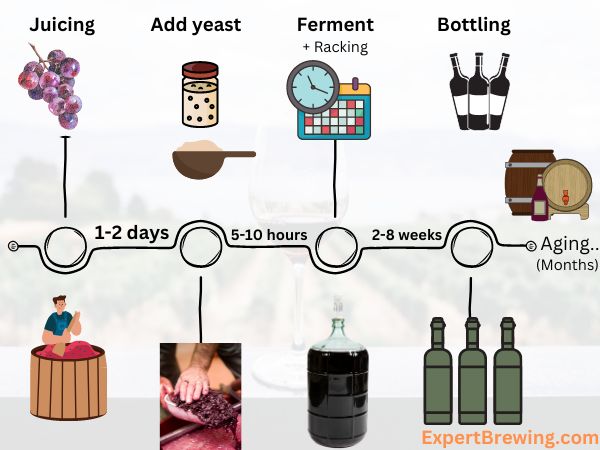

Primary fermentation is the initial stage of the brewing process where yeast converts sugars into alcohol and carbon dioxide.

During this phase, yeast consumes the fermentable sugars present in the wort, producing alcohol, carbon dioxide, and other flavor compounds.

Primary fermentation typically takes place in a fermenter, such as a glass carboy or stainless steel tank, and lasts for several days to a couple of weeks, depending on the beer style and desired flavor profile.

Here are some key points about primary fermentation:

- Purpose: Primary fermentation is crucial for converting sugars into alcohol and creating the foundation of flavor in the beer.

- Yeast: Yeast plays a vital role in primary fermentation, as it consumes the sugars and produces alcohol, carbon dioxide, and various flavor compounds.

- Temperature Control: Maintaining a consistent and controlled fermentation temperature is essential during primary fermentation to ensure yeast health and proper flavor development.

- Airlock Usage: During primary fermentation, an airlock is attached to the fermenter to allow the release of carbon dioxide while preventing oxygen and potential contaminants from entering the vessel.

- Krausen Formation: A thick layer of foam, known as krausen, forms on top of the fermenting beer during primary fermentation. This is a sign that the yeast is actively working.

- Rapid Gravity Decrease: Gravity readings are frequently taken during primary fermentation to monitor the progress of fermentation and determine when it is complete.

By understanding the primary fermentation process, homebrewers can lay a solid foundation for their beer’s flavor profile and prepare for the subsequent stage of secondary fermentation.

Secondary Fermentation

Secondary fermentation, also known as conditioning, is a process in brewing where the beer is transferred to a second container after primary fermentation.

The purpose of secondary fermentation is to further refine and mature the beer, allowing flavors to develop and any remaining yeast or sediment to settle.

This process can improve the clarity, flavor, and overall quality of the beer. It is particularly beneficial for high-alcohol beers, lagers, and beers that require extended aging. Secondary fermentation can take place in various containers such as carboys or oak barrels.

It is important to handle the transfer carefully to avoid introducing oxygen or contaminants.

When and why is secondary fermentation used?

Secondary fermentation is used in brewing to further develop the flavors and improve the overall quality of the beer.

It typically takes place after the initial fermentation, known as primary fermentation, where the majority of the alcohol is produced.

There are several reasons why brewers choose to utilize secondary fermentation:

- Clarification: Secondary fermentation helps to clarify the beer by allowing any remaining sediment or haze-causing substances to settle out. This results in a cleaner and clearer final product.

- Conditioning: During secondary fermentation, the beer undergoes a conditioning phase where it continues to mature and develop its flavors. This can lead to a smoother and more refined taste.

- Flavor Enhancement: Secondary fermentation allows for the development of unique and complex flavors. This is achieved through the interaction of the yeast with the remaining sugars and other compounds in the beer.

- Carbonation: This applies when using the secondary fermentation as a type of bottle conditioning . Some brewers choose to carbonate their beer through secondary fermentation by adding a small amount of sugar or carbonation drops. This can result in a natural and effervescent carbonation in the finished beer.

While secondary fermentation is not always necessary, it is commonly used in certain beer styles such as lagers, Belgian ales, and barrel-aged beers. It provides brewers with an opportunity to further enhance the quality and characteristics of their brews.

IV. Techniques for Secondary Fermentation

Containers used:

When it comes to secondary fermentation in brewing, there are various types of containers that can be used to facilitate the process.

Different containers offer different advantages and considerations, depending on the specific needs of the brew. Here are some common types of containers used for secondary fermentation:

- Carboys: Carboys are large glass or plastic containers that are often used for secondary fermentation. They provide a clear view of the fermentation process and are easy to clean. Glass carboys are preferred by some brewers because they do not absorb flavors or odors, while plastic carboys are lighter and less prone to breakage.

- Oak Barrels: Oak barrels are commonly used for secondary fermentation in wine production, as they impart unique flavors and aromas to the wine. These barrels are often used for aging and can enhance the complexity and character of the final product.

- Stainless Steel Tanks: Stainless steel tanks are popular in commercial brewing due to their durability and ease of cleaning. They are commonly used for secondary fermentation as they provide a controlled and sterile environment for the beer to age and condition.

- Kegs: Kegs can also be used for secondary fermentation, particularly in homebrewing. They offer convenience and portability, allowing for easy transportation and serving of the final product.

It’s important to consider the specific requirements of the brew when selecting a container for secondary fermentation. Factors such as oxygen exposure, temperature control, and flavors imparted by the container should be taken into account to achieve the desired outcomes.

Overall, the choice of container for secondary fermentation depends on the brewer’s preferences, equipment availability, and the specific characteristics desired in the final product.

Important factors when transferring for secondary fermentation

When transferring beer, wine, or cider for secondary fermentation, there are several important factors to consider to ensure a successful process:

- Sanitization: It is crucial to sanitize all equipment, including the transfer vessels, to prevent contamination and off-flavors in the final product.

- Oxygen Exposure: Minimizing oxygen exposure is essential during transfer to preserve the flavors and aromas of the beverage. Using a siphon or closed transfer system can help reduce the risk of oxidation.

- Temperature Control: Maintaining proper temperature during transfer is important to avoid any stress on the yeast and to ensure a consistent fermentation process.

- Sediment Separation: Care should be taken to leave behind any sediment or lees during transfer to achieve clarity and avoid unwanted flavors.

- Time Considerations: Transferring for secondary fermentation should be done at the appropriate time, depending on the specific beverage and desired outcome, such as clarifying the product or adding additional flavors.

Remember, each beverage may have unique considerations, so it’s important to research and follow specific guidelines for the best results.

| Factors to Consider | Importance 1-5 |

|---|---|

| Sanitization | 5 |

| Oxygen Exposure | 4 |

| Temperature Control | 2 |

| Sediment Separation | 3 |

| Timing | 3 |

Common methods of transferring beer, wine, or cider for secondary fermentation

When it comes to transferring beer, wine, or cider for secondary fermentation, there are several common methods that homebrewers can consider.

Each method has its own advantages and considerations, so it’s important to choose the one that best suits your needs and equipment.

- Siphoning: This is a popular method that involves using a siphon tube and a racking cane to transfer the liquid from one container to another. It helps to minimize oxygen exposure and sediment disturbance during the transfer. Gravity helps the transfer: Siphoning relies on gravity to move the liquid from a higher container to a lower one. It can be achieved by placing the primary vessel on an elevated surface and the secondary vessel on a lower level.

- Using a Transfer Pump: A transfer pump can be used to move the liquid from one container to another. This method ensures a precise and controlled transfer, but it may require additional equipment and setup.

- Counterflow or Plate Chillers: These devices can be used to transfer the liquid while simultaneously chilling it. They work by running the liquid through a heat exchanger, which cools it down before transferring it to the secondary container.

When choosing a transfer method, consider factors such as the volume of liquid being transferred, the presence of sediment or yeast, and the level of control and precision required. It’s also important to sanitize all equipment thoroughly to avoid contamination.

Summary Table:

| Method | Advantages | Considerations |

|---|---|---|

| Siphoning | Easy, cost effective. Minimizes oxygen exposure and sediment disturbance during transfer | Requires careful setup and caution to prevent contamination and sediment resuspension. |

| Using a Transfer Pump | Provides precise and controlled transfer | Requires more equipment and setup. Power consumption. |

| Counterflow or Plate Chillers | Enables simultaneous cooling and transfer | Requires expensive equipment and setup, may be more suitable for larger-scale operations |

Remember to always handle the liquid with care during the transfer to avoid introducing any unwanted flavors or contaminants.

Mistakes to avoid during the transfer process

When transferring beer, wine, or cider for secondary fermentation, there are several common mistakes that homebrewers should avoid to ensure the best possible outcome:

- Contamination: Ensure that all your equipment is properly sanitized to avoid introducing any unwanted bacteria or wild yeast strains during the transfer process.

- Oxygen Exposure: Minimize the exposure of your beverage to oxygen as it can lead to oxidation and off-flavors. Always use a siphoning or transferring method that reduces splashing and incorporates a non-return valve or a blanket of carbon dioxide to create a protective layer.

- Sediment Disturbance: Be careful not to disturb the sediment (yeast and other solids) at the bottom of the fermentation vessel during the transfer. Disturbing the sediment can result in cloudiness and off-flavors in the final product.

- Over-Exposure to Light: Protect your beer, wine, or cider from direct sunlight or bright artificial light. Light can lead to the degradation of aromas and flavors, causing skunking and off-tastes.

- Temperature Control: Maintain a stable temperature during the transfer process to avoid any fluctuations that may negatively impact the fermentation process.

- Improper Timing: Transfer your beverage at the appropriate time to ensure that primary fermentation is complete. Premature transfers can halt fermentation, leaving residual sugars and potentially causing overcarbonation in the bottle.

By being mindful of these mistakes, homebrewers can ensure a smooth and successful transfer to secondary fermentation, leading to improved clarity, flavor development, and overall quality in the final product.

V. Benefits of Secondary Fermentation

Improving clarity and flavor through extended aging

Improving clarity and flavor through extended aging is one of the key benefits of secondary fermentation in brewing. During this process, the beer, wine, or cider is transferred to a secondary container for a period of time to allow further fermentation and clarification.

Extended aging helps in the development of complex flavors, smoothens out any harsh or off-flavors, and enhances the overall quality of the beverage. It also promotes the settling of sediments and particles, resulting in a clearer and visually appealing final product.

Some important factors to consider when aging the beverage include temperature control, as different styles of beer or wine may require specific temperature ranges for optimal aging. It is also crucial to avoid exposure to light and oxygen, as these can negatively impact the flavor and aroma profile of the beverage.

By patiently allowing the beverage to age in a controlled environment, brewers and winemakers can achieve a more refined and enjoyable drinking experience. It is worth noting that the duration of secondary fermentation and aging will vary depending on the style of the beverage and personal preferences. Hence, experimentation and careful monitoring are essential to achieve the desired flavors and characteristics.

Reducing off-flavors and creating a smoother beer

During secondary fermentation in brewing, one of the main goals is to reduce off-flavors and create a smoother beer. This is achieved through a few key processes:

- Clarification: Racking the beer into a secondary fermenter allows for the sediment and particulate matter to settle, resulting in a clearer beer with improved appearance.

- Conditioning: Extended aging during secondary fermentation allows the beer to mature and develop complex flavors, while also allowing any remaining fermentation by-products to dissipate.

- Flavor Integration: Secondary fermentation provides an opportunity for flavors to integrate and mellow, resulting in a more balanced and enjoyable beer.

To achieve these goals, it is important to maintain proper temperature control and avoid exposing the beer to oxygen during transfer. This helps to minimize the risk of oxidation and off-flavors.

By carefully managing the secondary fermentation process, brewers can enhance the overall quality and flavor profile of their beer.

What are some downsides of doing secondary fermentation?

While secondary fermentation has its benefits, there are also some downsides to consider when deciding whether to use this method.

One potential downside is the risk of contamination during the transfer process. When transferring the beer, wine, or cider to another container for secondary fermentation, there is a chance of introducing unwanted bacteria or wild yeast. This can lead to off-flavors or spoilage of the beverage.

Another drawback is the need for additional equipment and storage space. Secondary fermentation typically requires a separate container, which means more equipment to clean and maintain. It also takes up additional space during the fermentation process.

Additionally, secondary fermentation can prolong the overall brewing timeline. While it may improve clarity and flavor, it also adds extra time to the fermentation process. This can be a downside for homebrewers who are looking for a quicker turnaround or who have limited patience for waiting.

Despite these potential drawbacks, many brewers still choose to use secondary fermentation for its benefits. It ultimately depends on personal preference and the specific goals of the brewing process.

VI. Common Misconceptions about Secondary Fermentation

Debunking myths and misconceptions surrounding secondary fermentation is crucial for understanding its true purpose and benefits in brewing. Here are some common misconceptions and the realities:

- Myth: Secondary fermentation is necessary for all types of beers.

Reality: Secondary fermentation is not mandatory for all beer styles. Some beers benefit from extended aging or clarification, while others can be bottled directly after primary fermentation. - Myth: Secondary fermentation is the same as conditioning.

Reality: Secondary fermentation is a distinct process that occurs after primary fermentation. Conditioning refers to the period of maturation and carbonation that follows secondary fermentation. - Myth: Transferring beer for secondary fermentation always leads to oxidation. Reality: If proper techniques are followed, the risk of oxidation during transfer can be minimized. It is important to use sanitized equipment, avoid excessive splashing, and limit exposure to oxygen.

- Myth: Secondary fermentation improves the flavor of all beers. Reality: While secondary fermentation can enhance certain beer flavors and aromas, it does not automatically improve every beer. Several factors, such as recipe design and yeast selection, contribute to the final flavor profile.

- Myth: Secondary fermentation is only necessary for high-alcohol beers. Reality: While high-alcohol beers may benefit from secondary fermentation, it is not limited to them. Beers of various styles can benefit from secondary fermentation for flavor development, clarity, and improved mouthfeel.

It is important to separate fact from fiction when it comes to secondary fermentation in brewing.

By understanding its purpose and debunking common myths, homebrewers can make informed decisions about whether to incorporate secondary fermentation into their brewing process.

What is the differences between secondary fermentation and (bottle) conditioning?

Secondary fermentation and conditioning are two distinct processes in the brewing industry, each serving a specific purpose, but they take place in much the same way.

Secondary fermentation focuses on continued fermentation and flavor development, while conditioning centers on maturation and stabilization.

Secondary fermentation:

- Occurs after primary fermentation and involves transferring the fermented liquid to a second container, such as a carboy or oak barrel.

- It allows for further fermentation and aging, leading to improved flavor development and clarity in the final product.

- In the case of carbonated beverages like sparkling wine, secondary fermentation traps carbon dioxide in the bottle, resulting in bubbly effervescence.

- Secondary fermentation can also include processes like malolactic fermentation, where harsh acids are converted into smoother ones.

Conditioning:

- Is usually done after all fermentation activity has halted.

- This step follows secondary fermentation and is focused on conditioning the beer, wine, or cider.

- Conditioning involves the maturation and stabilization of the product, allowing flavors to evolve and mellow.

- It may include processes like carbonation, filtering, or clarification to achieve the desired characteristics.

- Conditioning can take place in the same vessel used for secondary fermentation or in a separate container.

While secondary fermentation and conditioning are closely related, they serve different purposes.

Both processes are crucial in producing high-quality beverages with desirable characteristics.

VII. Tips for Successful Secondary Fermentation

To ensure a successful secondary fermentation in brewing, there are several best practices to follow:

- Timing: It is important to wait until primary fermentation is complete before transferring the beer, wine, or cider to the secondary fermentation vessel. This typically takes around one to two weeks, depending on the specific recipe and yeast used.

- Sanitation: As with any brewing process, maintaining proper sanitation is crucial. Make sure to thoroughly clean and sanitize the secondary fermentation vessel, as well as any tools or equipment used during the transfer.

- Oxygen exposure: Minimize the exposure of the beer, wine, or cider to oxygen during the transfer process. Oxygen can negatively impact the final product, leading to off-flavors and spoilage.

- Temperature control: Monitor and control the temperature of the secondary fermentation vessel. Different styles of beer may require specific temperature ranges for optimal fermentation.

- Racking: When transferring the beer, wine, or cider to the secondary fermentation vessel, try to minimize the transfer of sediment from the primary fermentation vessel. This can be achieved by siphoning the liquid carefully and leaving behind any sediment or trub at the bottom.

- Airlock or sealing: Ensure that the secondary fermentation vessel is properly sealed with an airlock or airtight seal to prevent contamination and maintain a fermenting environment.

- Aging: Depending on the style of beer or desired flavor profile, longer aging during secondary fermentation can improve clarity, flavor development, and smoothness. Consider the specific aging requirements for the style being brewed.

Following these best practices can help homebrewers achieve a successful secondary fermentation and produce high-quality beer, wine, or cider. Remember to experiment and adjust the process based on individual preferences and brewing goals.

Temperature control and monitoring during secondary fermentation

Temperature control and monitoring during secondary fermentation is crucial to ensure the desired flavors and aromas are developed in the beer, wine, or cider.

The primary fermentation phase usually takes place at a slightly higher temperature to allow the yeast to be more active and produce the desired flavors and alcohol content.

However, during secondary fermentation, it is important to maintain a lower and stable temperature to control the fermentation process and avoid off-flavors. This can be achieved by using a fermentation chamber or utilizing temperature control devices such as thermostats or cooling systems.

Regularly monitoring the temperature and making adjustments if necessary will ensure the best results for your secondary fermentation. It is also important to note that different styles of beer may require specific temperature ranges for secondary fermentation, so it’s crucial to refer to specific brewing guidelines for the desired style.

VIII. Examples of Beers that Benefit from Secondary Fermentation

Styles of beer that typically undergo secondary fermentation include:

- Belgian-style Ales: These beers are known for their complex flavors and aromas, which are often the result of secondary fermentation. Examples include Belgian Tripels, Dubbels, and Lambics.

- Sour Beers: Sour beers, such as Gueuze and Flanders Red Ale, often undergo secondary fermentation with wild yeast or bacteria to achieve their characteristic tartness and funky flavors.

- Fruit Beers: Many fruit beers, like Raspberry Lambics or Cherry Saisons, undergo a secondary fermentation with added fruit to enhance the flavor and aroma of the beer.

- Strong Ales: Beers with high alcohol content, such as Barleywines and Imperial Stouts, can benefit from secondary fermentation to mellow and age the flavors, resulting in a smoother and more complex beer.

- Bottle-conditioned Beers: Bottle-conditioned beers, like Trappist ales or some IPA styles, undergo a secondary fermentation in the bottle. This involves adding a small amount of yeast and sugar to carbonate the beer naturally, resulting in a more lively and effervescent beer.

Secondary fermentation is particularly common in styles that benefit from extended aging and development of unique flavors. It allows for the refinement of flavors, the creation of carbonation, and the maturation of the beer over time.

Through the process of secondary fermentation, brewers can achieve a greater depth of flavor and complexity in their beers.

Final thoughts and considerations for homebrewers

When it comes to secondary fermentation in brewing, there are a few important considerations for homebrewers to keep in mind. Here are some final thoughts to help you navigate this process effectively:

- Sanitation is crucial: Make sure to thoroughly clean and sanitize all equipment, including fermentation vessels, airlocks, and siphoning tools. This will help prevent any contamination and off-flavors in your beer.

- Transfer carefully: When transferring your beer, wine, or cider to a secondary fermentation vessel, be cautious not to introduce excessive oxygen, as this can lead to oxidation and spoilage. Consider using a siphoning technique or a closed transfer system to minimize oxygen exposure.

- Temperature control: During secondary fermentation, it’s essential to maintain a stable temperature within the optimal range for your specific style of beer. This will ensure proper yeast activity and flavor development. Consider using a temperature-controlled fermentation chamber or wrap your fermentation vessel with insulation to regulate temperature fluctuations.

- Aging and clarity: Secondary fermentation provides an opportunity for extended aging, which can improve the clarity and flavor of your beer. Allow your brew to sit undisturbed for the desired length of time, ensuring that any sediment settles to the bottom.

- Taste testing: Throughout the secondary fermentation process, periodically sample your beer to assess its progress and flavor. This will help you determine if any adjustments or additions are necessary.

- Seek guidance: If you’re new to homebrewing or secondary fermentation, don’t hesitate to seek advice and guidance from experienced brewers or join a homebrewing community. They can offer valuable insights and troubleshooting tips to ensure your brewing journey is successful.

Remember, secondary fermentation is not always necessary for every beer style. Understanding the specific requirements and characteristics of the style you’re brewing will guide your decision-making process.

By following best practices, maintaining sanitation, and monitoring fermentation conditions, you can enhance the flavor, clarity, and overall quality of your homebrewed beer.

IX. Conclusion

Secondary fermentation plays a crucial role in the brewing process, and its importance and advantages cannot be overlooked. Here is a summary of why secondary fermentation is essential in brewing:

- Clarification: During secondary fermentation, the beer, wine, or cider undergoes a settling process, allowing any remaining sediment or solids to settle at the bottom of the container. This improves the clarity of the final product.

- Flavor development: Secondary fermentation provides an opportunity for flavors to mellow and blend, resulting in a smoother and more balanced taste. It allows for the development of desirable flavors and the reduction of any off-flavors.

- Carbonation: In certain styles of beer, secondary fermentation is crucial for achieving carbonation. The addition of priming sugar or yeast in the secondary vessel allows for the natural production of carbon dioxide, resulting in a fizzy and sparkling beverage.

- Conditioning: Extended aging during secondary fermentation can improve the overall quality and character of the beer, wine, or cider. It allows the flavors to mature and become more complex.

- Yeast management: Secondary fermentation helps to separate the beer, wine, or cider from the yeast sediment accumulated during primary fermentation, ensuring a cleaner and clearer final product.

It is important to note that not all styles of beer or alcoholic beverages require secondary fermentation.

Some brews, such as quick-maturing ales, may skip this step altogether. Nonetheless, for many brewers, secondary fermentation is an essential part of the brewing process to achieve the desired clarity, flavor profile, and carbonation.

Cheers to successful secondary fermentation and enjoyable brewing experiences!