As a home brewer, I’ve spent countless hours tinkering with different yeast strains, sugar sources, and water profiles to create the perfect fermentation environment for my beers.

In this blog post, I’ll share my experiences and insights into the magical world of fermentation, where simple ingredients like yeast, sugar, and water can transform into delicious bread, beer, wine, and more.

But what happens if you mix these three ingredients one their own? Well, it will also ferment, but not into something very interesting.

The yeast will also (eventually) need more nutrients (minerals and amino acids) than the sugar provided if you want a high amount of alcohol.

We’ll dive into the science behind fermentation, discuss various types of yeast and sugar sources, and explore ways to control and optimize the fermentation process for your home brewing or baking needs.

The Science of Fermentation

Fermentation is a natural metabolic process that occurs when microorganisms like yeast consume sugars and produce energy in the form of alcohol and carbon dioxide gas.

The process begins when you mix yeast, sugar, and water, and it’s critical for making bread rise and creating the bubbly texture in beer and other fermented beverages.

When you add yeast to a sugar solution, the yeast cells consume the sugar and break it down into alcohol and carbon dioxide gas.

This is known as alcoholic fermentation. In bread making, the carbon dioxide gas produced during fermentation gets trapped in the dough, causing it to rise and creating a light, airy texture.

In brewing, the alcohol produced during fermentation is responsible for the intoxicating effects of beer, while the carbon dioxide gas creates the bubbles and effervescence we associate with a refreshing pint.

Different Types of Yeast

When it comes to fermentation, not all yeast strains are created equal. There are hundreds of different types of yeast, each with its unique characteristics and flavors.

Some of the most common yeast strains used in home brewing and baking include:

- Saccharomyces cerevisiae: This is the most common yeast strain used in bread making and brewing ales. It ferments at warmer temperatures and produces fruity esters, which can add complexity and depth to your final product.

- Saccharomyces pastorianus: This yeast strain is used primarily in brewing lagers. It ferments at cooler temperatures and produces fewer esters, resulting in a cleaner, more crisp flavor profile.

- Brettanomyces: This is a wild yeast strain that is often used in sour beers and other funky, complex fermentations. It can produce a wide range of flavors, from fruity and tropical to earthy and barnyard-like.

When selecting a yeast strain for your fermentation project, it’s essential to consider the desired flavor profile and fermentation temperature.

Experimenting with different yeast strains can be a fun and rewarding way to add variety and complexity to your homebrewed beers and baked goods.

Sugar Sources

Yeast can ferment a wide range of sugars, including glucose, fructose, sucrose, and maltose. The type of sugar you use in your fermentation will have a significant impact on the final product’s flavor and mouthfeel.

Here are some sugars, along with information about where they are found and how they are fermented in alcohol fermentation:

Glucose:

- Found in: Glucose is a simple sugar that is commonly found in fruits, vegetables, and honey. It is also a primary product of photosynthesis in plants.

- Fermentation: In alcohol fermentation, glucose is broken down by yeast or certain bacteria through a process called glycolysis. This process converts glucose into pyruvate, releasing energy in the form of ATP. The pyruvate is then further metabolized into ethanol and carbon dioxide.

Fructose:

- Found in: Fructose is a natural sugar commonly found in fruits, vegetables, and honey. It is the sweetest naturally occurring sugar.

- Fermentation: Fructose can also be fermented by yeast or bacteria through glycolysis, similar to glucose. It is converted into pyruvate, which is further metabolized into ethanol and carbon dioxide during alcohol fermentation.

Sucrose:

- Found: Sucrose is a disaccharide composed of glucose and fructose. It is the primary sugar found in sugar cane, sugar beets, and various fruits and vegetables.

- Fermentation: In alcohol fermentation, yeast or bacteria first break down sucrose into its constituent glucose and fructose molecules using the enzyme invertase. The glucose and fructose are then individually fermented through glycolysis, producing ethanol and carbon dioxide.

Honey:

- Found: Honey is a natural sweetener produced by bees from the nectar of flowers. It contains various sugars, including glucose and fructose, with smaller amounts of sucrose and other carbohydrates.

- Fermentation: Honey can undergo spontaneous fermentation if it contains wild yeast. The yeast converts the glucose and fructose present in honey into ethanol and carbon dioxide through glycolysis, resulting in the formation of mead, an alcoholic beverage.

Maltose:

- Found in: Maltose is a disaccharide composed of two glucose molecules. It is primarily found in germinating grains, such as barley and malted barley.

- Fermentation: Maltose is fermented by yeast during alcohol fermentation. The yeast produces an enzyme called maltase, which breaks down maltose into two glucose molecules. The glucose is then metabolized through glycolysis to produce ethanol and carbon dioxide.

In alcohol fermentation, the common pathway is the conversion of various sugars into pyruvate through glycolysis. The pyruvate is subsequently metabolized into ethanol and carbon dioxide, which are the desired products of alcohol fermentation. Different sugars serve as substrates for yeast or bacteria, providing a source of energy for their metabolic processes and producing alcohol as a byproduct.

In beer brewing, the primary source of sugar is malted barley, which is mashed to extract the sugars e.g. maltose necessary for fermentation.

Other grains like wheat, rye, and oats can also be used, each contributing their unique flavors and textures to the final product.

In baking, table sugar (sucrose) is the most common sugar source. However, other sugars like honey, molasses, and maple syrup can also be used to create different flavors and textures in your baked goods.

Water Quality

The quality of the water you use in your fermentation can have a significant impact on the final product.

Water with high levels of minerals, chlorine, or other impurities can negatively affect the fermentation process and alter the flavor of your bread, beer, or wine.

When brewing or baking, it’s essential to use clean, filtered water to ensure a healthy fermentation and a delicious final product.

Temperature Control

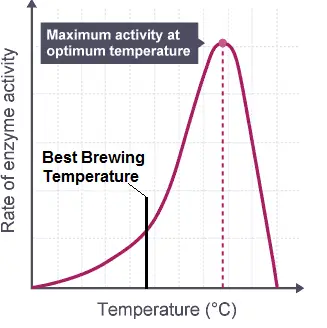

The temperature at which you ferment your yeast, sugar, and water mixture plays a critical role in determining the final product’s flavor and character.

Different yeast strains have different optimal fermentation temperatures, and controlling the temperature during fermentation can significantly impact the final product.

For example, ale yeast strains typically ferment best at temperatures between 60-75°F (15-24°C), while lager yeast strains prefer cooler temperatures, around 50-55°F (10-13°C).

Fermenting at temperatures outside the optimal range for your yeast strain can result in off-flavors or stalled fermentations.

Investing in a temperature-controlled fermentation chamber or using a water bath to maintain a consistent fermentation temperature can be a game-changer for your homebrewed beers and baked goods.

Monitoring Fermentation Progress

Keeping an eye on your fermentation progress is essential to ensure a successful outcome. In brewing, this typically involves measuring the specific gravity of your beer using a hydrometer.

As the yeast consumes the sugars in your wort, the specific gravity will decrease, allowing you to track the fermentation’s progress and determine when it’s complete.

In baking, monitoring fermentation progress is more of an art than a science. You’ll need to observe the dough’s rise and texture, perform the “poke test” to check for proper gluten development, and rely on your senses to know when the fermentation is complete.

Troubleshooting Fermentation Issues

Sometimes, despite your best efforts, fermentation issues can arise. Some common problems and their possible solutions include:

- Stuck fermentation: If your fermentation stalls or fails to start, it could be due to an issue with the yeast (e.g., old or improperly stored yeast) or inadequate nutrients. You can try adding a yeast nutrient, pitching more yeast, or gently stirring the mixture to re-suspend the yeast and encourage fermentation.

- Off-flavors: If your final product has an off-flavor, it could be due to an issue with the fermentation temperature, water quality, or contamination. Ensure you’re fermenting at the proper temperature, using clean, filtered water, and practicing good sanitation to avoid introducing unwanted bacteria or wild yeast strains into your fermentation.

- Over-carbonation: If your beer is excessively carbonated or foamy, it could be due to an overactive fermentation, contamination, or bottling too soon. Ensure your fermentation is complete by checking the specific gravity and allowing enough time for the yeast to consume any residual sugars before bottling.

Experimentation and Creativity

One of the joys of working with yeast, sugar, and water is the endless possibilities for experimentation and creativity. By playing with different yeast strains, sugar sources, and fermentation conditions, you can create a wide range of unique and delicious bread, beer, wine, and more.

Don’t be afraid to think outside the box and try new things – the worst that can happen is a batch that doesn’t turn out quite as planned, but the best-case scenario is discovering a new favorite recipe or technique.

Conclusion

When you mix yeast, sugar, and water, you kick-start a fascinating fermentation process that can produce a wide range of delicious products, from bread to beer and beyond. As a home brewer or baker, understanding and controlling this process is essential for creating consistently delicious results.

Here are ten key takeaways from our deep dive into the world of fermentation:

1. Fermentation is the process of yeast consuming sugars and producing alcohol and carbon dioxide gas.

2. The type of yeast strain you use can significantly impact the final product’s flavor and character.

3. Different sugar sources can be used to create a variety of flavors and textures in your fermented products.

4. The quality of water used in your fermentation is crucial for a successful outcome.

5. Proper temperature control during fermentation can greatly influence the final product’s taste and aroma.

6. Monitoring the progress of your fermentation is essential for determining when it is complete.

7. Troubleshooting and addressing fermentation issues can help ensure a successful outcome.

8. Experimenting with different yeast strains, sugar sources, and fermentation conditions can lead to exciting and unique results.

9. The endless possibilities for experimentation and creativity are what make working with yeast, sugar, and water so rewarding and enjoyable.

10. Understanding and controlling the fermentation process is key to creating consistently delicious home-brewed beers and baked goods.