When it comes to the art of brewing, there’s no denying that oxygen plays a crucial role – but only at the right time. In the early stages of brewing, oxygen provides the yeast with the energy it needs to reproduce and kick start the fermentation process.

However, oxygen can be a brewer’s worst enemy in the late stages of brewing. But why exactly is oxygen bad in the late stages of brewing?

Oxygen can cause significant damage to your beer in the late stages of brewing, leading to off-flavors, a shortened shelf-life, and diminished overall quality. Let’s delve into the details of why this is the case, and how you can prevent oxygen exposure in your brewing process.

The Dangers of Oxygen Exposure

Oxidation and Off-Flavors

The most common problem brewers encounter with oxygen is the risk of oxidation. When beer comes into contact with oxygen after fermentation, it can result in various off-flavors, often described as stale, cardboard-like, or sherry-like.

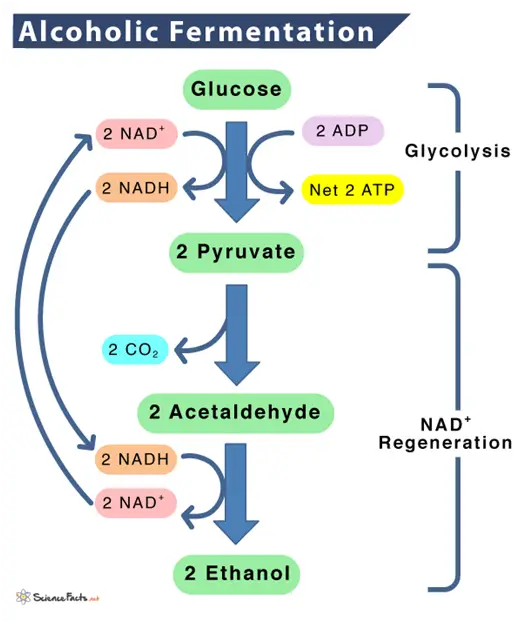

Oxygen reacts with the alcohol in your beer, producing aldehydes and ketones that contribute to these unwelcome flavors.

Shortened Shelf-Life

Another issue with oxygen exposure is that it can drastically reduce your beer’s shelf-life. Oxygen accelerates the aging process, causing your beer to taste ‘old’ or ‘stale’ much faster than it should. This is a particular issue for commercial brewers, as it can lead to significant product waste.

Oxygen and the Brewing Process

Early Stage Oxygen Exposure

During the early stages of brewing, particularly the aeration phase, oxygen is actually beneficial. Yeast cells use oxygen to reproduce and generate energy, setting up the fermentation process.

However, once fermentation begins, the yeast switches to an anaerobic mode of operation, no longer requiring oxygen. From this point on, any exposure to oxygen can be detrimental.

Late Stage Oxygen Exposure

In the late stages of brewing, particularly during transfer, packaging, and storage, oxygen exposure can occur. This is when the risk of oxidation and the subsequent production of off-flavors and shortened shelf-life becomes a significant concern. It’s crucial to minimize oxygen exposure during these stages.

How to Prevent Oxygen Exposure

Preventing oxygen exposure during the late stage of fermentation is crucial to ensure the quality and flavor profile of your fermented product.

Oxygen can lead to oxidation, off-flavors, and potential spoilage. Here are some steps you can take to minimize oxygen exposure during late-stage fermentation:

- Use an Airtight Fermentation Vessel: Choose a fermentation vessel with airtight seals to prevent oxygen from entering. This could be a glass carboy, stainless steel fermenter, or another vessel specifically designed for fermentation.

- Minimize Transfers: Limit the number of times you transfer your fermenting product between vessels. Each transfer introduces the risk of oxygen exposure. If necessary, plan your fermentation vessel size to accommodate the entire fermentation process without the need for transfers.

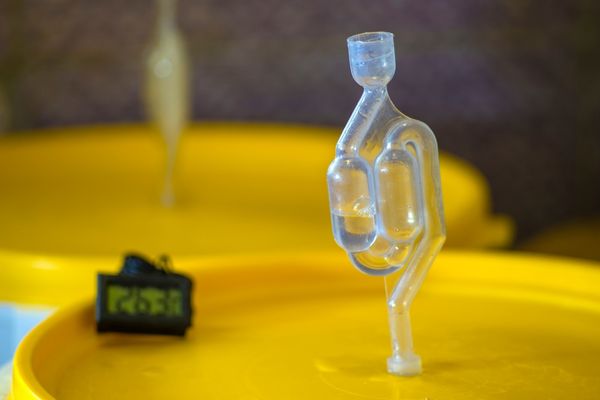

- Airlock System: Use an airlock system on your fermentation vessel. An airlock allows gases produced during fermentation to escape while preventing external air from entering. This maintains a barrier against oxygen exposure.

- Avoid Agitation: Excessive stirring or agitation during the late stages of fermentation can introduce oxygen. Minimize any unnecessary movement of the fermentation vessel.

- Purge with Inert Gas: Before sealing your fermentation vessel, consider purging it with an inert gas like nitrogen or carbon dioxide. This displaces the oxygen inside the vessel, creating a protective atmosphere.

- Ferment in Closed System: If possible, ferment in a closed system that allows for the release of excess gas without exposing the fermenting product to outside air. This could involve using specialized airlock systems or fermentation bags.

- Top-Up Method: For beverages like wine or beer, where there might be headspace in the fermentation vessel, consider the top-up method. This involves adding additional liquid (of the same type as what you’re fermenting) to fill the headspace and minimize oxygen exposure.

- Use Oxygen Scavengers: In some cases, you might use oxygen-scavenging compounds or sachets that absorb any residual oxygen in the fermentation vessel.

- Temperature Control: Maintain stable fermentation temperatures. Fluctuations in temperature can cause pressure changes inside the fermentation vessel, potentially leading to oxygen being drawn in.

- Monitor and Seal Leaks: Regularly check your fermentation vessel for any leaks or breaches in the seal. Repair or replace any faulty components to maintain an airtight environment.

- Timely Racking: If your fermentation process involves racking (transferring from one vessel to another to separate the liquid from sediment), ensure it’s done carefully and quickly to minimize oxygen exposure.

- Finishing Stages: If possible, conduct any necessary activities, such as adding fining agents or flavor additives, before the late stage of fermentation. This reduces the need for additional interventions that could introduce oxygen.

Remember that the specific steps you need to take will vary based on the type of fermentation you’re conducting (e.g., beer, wine, sauerkraut, etc.).

It’s important to research and understand the best practices for your particular fermentation process to ensure optimal results and product quality.

Using CO2

One of the most effective ways to prevent oxygen exposure is to use CO2. By purging your vessels with CO2 before transfers, you can create an oxygen-free environment. This is particularly useful during bottling or kegging, where the risk of oxygen exposure is high.

Proper Equipment Maintenance

Maintaining your equipment is also key in preventing oxygen exposure. Ensure all seals and gaskets are in good condition, and regularly check your equipment for leaks. Any small leaks can allow oxygen to sneak into your closed system and wreak havoc on your brew.

Conclusion

So, there you have it – the reason why oxygen is bad in the late stages of brewing. While oxygen is beneficial in the early stages, helping yeast cells to reproduce and generate energy.

It can cause significant damage to your beer, wine or cider in the late stages, leading to off-flavors, a shortened shelf-life, and diminished overall quality.

To summarize, here are the key points:

1. Oxygen exposure can lead to oxidation, resulting in off-flavors.

2. Oxygen accelerates the aging process, shortening your beer’s shelf-life.

3. Oxygen is beneficial in the early stages of brewing, aiding yeast reproduction and energy generation.

4. Late-stage oxygen exposure can occur during transfer, packaging, and storage.

5. Use of CO2 can help prevent oxygen exposure.

6. Proper equipment maintenance is crucial to preventing oxygen exposure.

7. Oxygen exposure can lead to significant product waste, particularly for commercial brewers.

8. Oxygen reacts with alcohol in beer to produce aldehydes and ketones, contributing to off-flavors.

9. Even small leaks in storage equipment can allow oxygen to enter.

10. Creating an oxygen-free environment during bottling or kegging can significantly reduce the risk of oxidation and contamination.

From personal experience, I can attest to the importance of preventing oxygen exposure in the late stages of brewing.

I’ve learned the hard way that a seemingly small oversight in this area can have a significant impact on the taste and quality of the final product. So, fellow brewers, remember to always give oxygen the attention it deserves in your brewing process – your beer will thank you for it!

FAQs

What is the effect of oxygen in fermentation process?

Oxygen has a detrimental effect on the fermentation process. It inhibits the growth and activity of yeast or bacteria responsible for fermentation.

Can yeast ferment without oxygen?

Yes, yeast can ferment without oxygen.

Do brewers care about oxygen in finished beer?

Yes, brewers do care about oxygen in finished beer. Oxygen can negatively impact the flavor, aroma, and stability of beer. It can lead to oxidation, causing off-flavors and stale characteristics. Brewers take measures to minimize oxygen exposure during packaging and storage to ensure the beer maintains its desired quality.

Does fermentation need oxygen to function?

No, fermentation does not require oxygen to function.

Do brewers add CO2 to beer?

Yes, brewers do add carbon dioxide (CO2) to beer during the brewing process. This is done to achieve the desired level of carbonation in the final product.

Does oxygen promote fermentation?

No, oxygen does not promote fermentation. In fact, fermentation is an anaerobic process that occurs in the absence of oxygen.