Belgian Dubbels are a classic beer style that has captivated the palates of beer enthusiasts all over the world. Known for their rich, malty flavors, and subtle notes of dark fruit and spice, they are a true testament to the art of brewing. One of the most important aspects of creating a delicious Belgian Dubbel is the conditioning time.

The ideal conditioning time for a Belgian Dubbel is typically between 4 to 6 weeks. This allows for the flavors to meld and develop, resulting in a more complex and enjoyable beer.

In this blog post, I will discuss the ideal conditioning time for a Belgian Dubbel, as well as delve into various factors that can affect the overall flavor and quality of the finished beer.

The Role of Conditioning in Beer Brewing

Conditioning is a crucial step in the beer brewing process, as it allows the beer to mature and develop its flavors. During conditioning, the beer undergoes several chemical transformations, including the breakdown of complex sugars, the reduction of sulfur compounds, and the development of esters and other flavor compounds.

The conditioning process can be broken down into two main stages: primary and secondary fermentation. Primary fermentation is where the yeast consumes the sugars present in the wort, producing alcohol and carbon dioxide. Secondary fermentation, also known as conditioning, is when the beer is transferred to a separate vessel, allowing the yeast to consume any remaining sugars and clean up off-flavors produced during primary fermentation.

The length of conditioning time can vary depending on the beer style, yeast strain, and desired flavor profile. For a Belgian Dubbel, a longer conditioning period of 4 to 6 weeks is recommended.

Factors Affecting Conditioning Time

Yeast Strain

The choice of yeast strain can have a significant impact on the conditioning time and overall flavor of a Belgian Dubbel. Traditional Belgian yeast strains are known for their ability to produce complex esters and phenols that contribute to the beer’s signature fruity and spicy flavors. Some yeast strains may require longer conditioning times to fully develop these flavors.

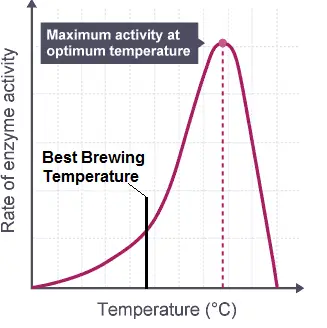

Fermentation Temperature

The temperature at which fermentation occurs can also impact the conditioning time of a Belgian Dubbel. Belgian yeast strains typically perform best at higher temperatures, around 65-75°F (18-24°C).

Fermenting at the higher end of this range can result in a faster fermentation and more pronounced esters, while fermenting at the lower end can lead to a cleaner flavor profile and potentially longer conditioning times.

Original Gravity

The original gravity (OG) of the beer is a measure of the sugar content in the wort before fermentation. A higher OG Belgian Dubbel will have more fermentable sugars, resulting in a higher alcohol content and a longer conditioning time to allow the flavors to mellow and meld together.

Aging and Carbonation Methods

The method used for aging and carbonating the beer can also impact conditioning time. Bottle conditioning, where the beer is naturally carbonated in the bottle by adding a small amount of sugar or wort, can take longer than force carbonating in a keg. This is because bottle conditioning requires additional time for the yeast to consume the added sugar and produce carbon dioxide.

Taste Test and Adjustments

Conditioning times can vary, and the best way to determine if a Belgian Dubbel is ready for consumption is by taste testing. After the recommended 4 to 6 weeks of conditioning, sample the beer to see if the flavors have developed to your liking. If the beer is still too sweet or has off-flavors, allow it to condition for another week or two before tasting again.

Patience is Key

When brewing a Belgian Dubbel, it’s essential to remember that patience is key. Rushing the conditioning process can result in an underdeveloped and less enjoyable beer. Giving the beer ample time to condition will allow the complex flavors to fully develop, resulting in a delicious and rewarding final product.

The Rewards of Proper Conditioning

The benefits of giving a Belgian Dubbel the proper conditioning time are well worth the wait. A well-conditioned Dubbel will have a rich, malty backbone, complemented by notes of dark fruit, caramel, and subtle spices. The flavors will meld together, creating a harmonious and complex beer that is both satisfying and enjoyable.

Conclusion

The ideal conditioning time for a Belgian Dubbel is typically between 4 to 6 weeks. This allows for the flavors to meld and develop, resulting in a more complex and enjoyable beer. Here are some key facts to remember about Belgian Dubbel conditioning:

1. Conditioning is a crucial step in the beer brewing process, allowing the beer to mature and develop its flavors.

2. The conditioning process can be broken down into primary and secondary fermentation.

3. The length of conditioning time can vary depending on the beer style, yeast strain, and desired flavor profile.

4. Traditional Belgian yeast strains contribute to the fruity and spicy flavors characteristic of a Belgian Dubbel.

5. Fermentation temperature can impact the conditioning time and flavor profile of the beer.

6. The original gravity of the beer can affect the conditioning time, with higher OG beers requiring longer periods.

7. The method used for aging and carbonating the beer can also impact conditioning time.

8. Taste testing the beer after the recommended conditioning period can help determine if it’s ready for consumption.

9. Patience is key when brewing a Belgian Dubbel, as rushing the conditioning process can result in underdeveloped and less enjoyable beer.

10. A well-conditioned Belgian Dubbel will have a rich, malty backbone, complemented by notes of dark fruit, caramel, and subtle spices.

FAQs

Can a beer bottle condition in 1 week?

It is possible for a beer to condition in 1 week, but the amount of carbonation and flavor development may be limited. It is generally recommended to condition beer for 2-4 weeks for optimal results.

Can you ferment beer in a week?

Yes, it is possible to ferment beer in a week, but it depends on the type of beer, the yeast strain used, and the fermentation conditions. Some beers, such as light lagers, can be fermented in as little as 5-7 days, while others, such as high gravity ales, may take several weeks to ferment fully. It is important to monitor the fermentation process closely and ensure that the yeast has enough time to complete its job before bottling or kegging the beer.

How long does it take to condition a beer bottle?

Conditioning a beer bottle can take anywhere from a few days to several months, depending on the style and alcohol content of the beer, as well as personal preference.

How long does it take for a beer bottle to carbonate?

It typically takes 1-2 weeks for a beer bottle to carbonate, depending on factors such as temperature and yeast activity.

How can I speed up my beer bottle conditioning?

It is not recommended to speed up the beer bottle conditioning process as it can negatively affect the quality and taste of the beer. The optimal time for bottle conditioning is typically 1-2 weeks at room temperature. However, if you are in a hurry, you can try increasing the temperature slightly (not exceeding 75°F) to speed up the process, but be cautious as this can also cause over-carbonation and off-flavors.

How long should I bottle condition my beer?

The length of time for bottle conditioning beer depends on the style of beer and the desired level of carbonation. Generally, a minimum of two weeks is recommended, but some styles may require longer conditioning times. It is recommended to check the carbonation level by opening a bottle after two weeks and adjusting the conditioning time accordingly.

-recipe.jpg)