Malolactic fermentation is a fascinating process that can greatly impact the flavor, aroma, and overall quality of the final product.

In this comprehensive guide, we will delve into all aspects of malolactic fermentation, from its fundamental principles to its potential benefits and risks. We will explore the steps involved in the fermentation process, the key factors that can influence its outcome, and the methods for controlling and monitoring the fermentation in beer production.

Whether you are a brewing enthusiast or a professional in the industry, understanding malolactic fermentation is crucial for achieving the desired characteristics in sour and fruit beers. So, let’s embark on this exploration to uncover the secrets of malolactic fermentation and its significance in the world of beer.

Key Takeaways:

- Malolactic fermentation can enhance the flavor, aroma, and mouthfeel of beer, making it a popular process for many brewers.

- Proper monitoring and control of temperature, pH level, and nutrients are crucial for a successful malolactic fermentation process.

- While malolactic fermentation can improve beer, it also carries some risks such as off-flavors and contamination, which can be mitigated with proper techniques and tools.

What Is Malolactic Fermentation?

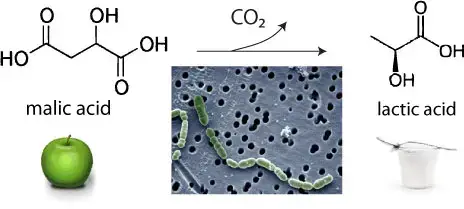

Malolactic fermentation (MLF) is a secondary fermentation process in winemaking, primarily driven by lactic acid bacteria (LAB) such as Oenococcus, Lactobacillus, and Pediococcus.

During MLF, lactic acid bacteria convert malic acid into lactic acid and carbon dioxide, reducing the overall acidity of the wine. This process is particularly beneficial for red wines and some full-bodied white wines, as it can soften the harshness and enhance the overall flavor profile. Lactic acid, a milder acid compared to malic acid, can contribute to a smoother mouthfeel and enrich the wine’s complexity.

The involvement of LAB in MLF also plays a crucial role in stabilizing the wine by consuming any residual sugar and producing diacetyl and other flavor compounds, further contributing to the sensory characteristics of the wine. The reduction of acidity during MLF can lessen the need for chemical additives, aligning with the growing preference for natural winemaking processes.

Sour Beers and Fruit Beers

The application of malolactic fermentation (MLF) extends beyond winemaking, as it is also utilized in the production of sour beers and fruit beers, where specific LAB strains engage in a microbial competition to influence the final flavor profile.

In terms of sour beers, MLF plays a crucial role in refining the tartness and complexity of flavors. Certain Lactic Acid Bacteria (LAB) strains such as Lactobacillus and Pediococcus are involved in MLF, contributing to the characteristic tangy and acidic notes in sour beers. In the realm of fruit beers, MLF enhances the integration of fruit flavors by transforming harsh malic acid into the softer lactic acid, resulting in a smoother taste with balanced acidity.

The fermentation process during MLF introduces a distinctive depth of aroma and mouthfeel, enriching the sensory experience of the beer.

This process also presents a competitive environment among microbial agents, where the delicate balance of microorganisms dictates the development of the beer’s flavor.

This dynamic interplay among the various strains of yeast, bacteria, and other microflora ultimately shapes the beer’s unique and complex attributes, reinforcing the critical role of MLF in craft brewing.

What Are the Benefits of Malolactic Fermentation in Beer?

The incorporation of malolactic fermentation (MLF) in beer offers several benefits, including the enhancement of aroma and flavor complexities through the activity of specific bacterial strains.

MLF not only contributes to the development of unique sensory characteristics in beer, but also plays a crucial role in reducing acidity, improving the stability, and refining the mouthfeel of the final product. The participation of selected bacterial strains in MLF introduces desirable changes, such as the conversion of malic acid into lactic acid, thereby imparting a smoother acidity profile and enriching the overall sensory experience for consumers.

Improved Flavor and Aroma

The primary benefit of malolactic fermentation (MLF) in beer lies in the improvement of flavor and aroma, achieved through the metabolic activities of specific bacterial strains that introduce unique sensory complexities.

By facilitating the conversion of malic acid to lactic acid, these bacterial strains not only reduce the acidity but also impart a smooth, creamy texture to the beer. MLF plays a crucial role in enhancing the fruity and buttery notes, thereby contributing to a more rounded and harmonious sensory profile.

The interaction between the bacterial strains and the beer’s existing components results in a more refined and balanced flavor, elevating the overall drinking experience.

Increased Stability and Shelf Life

Malolactic fermentation (MLF) contributes to the increased stability and extended shelf life of certain beer styles, as the reduction in acidity resulting from bacterial activities enhances the overall product preservation.

This process plays a crucial role in influencing the sensory characteristics of beers by reducing the harshness of acidity and imparting a smoother mouthfeel. The conversion of malic acid into lactic acid during MLF not only contributes to flavor development but also inhibits the growth of undesirable microorganisms, thereby prolonging the shelf life of the beer.

The alteration in acidity levels achieved through MLF can contribute to the overall stability of the beer by minimizing the risk of spoilage, thus ensuring a consistent and high-quality product for consumers.

Enhanced Mouthfeel

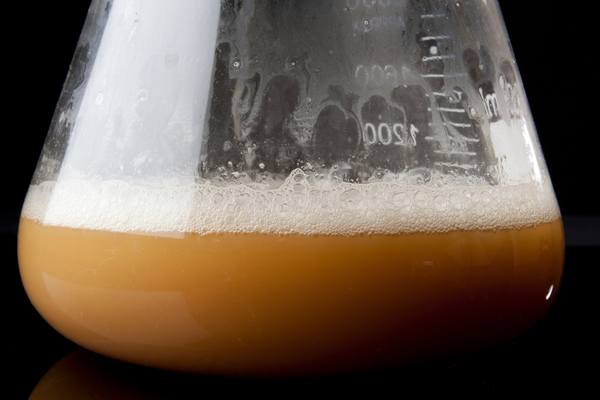

The incorporation of malolactic fermentation (MLF) in beer production contributes to an enhanced mouthfeel, as the bacterial activities during the fermentation process introduce textural complexities and richness to the final product.

.jpg)

MLF impacts the mouthfeel of beers by influencing the perception of creaminess, smoothness, and fullness. This is achieved through the conversion of harsh malic acid into milder lactic acid by bacteria, which can result in a softer and rounded mouthfeel. The release of certain compounds during MLF, such as diacetyl, also contributes to the texture by adding a buttery or creamy sensation. The reduction of acidity due to MLF can enhance the overall perception of balance and roundness in the beer’s mouthfeel.

What Are the Steps in Malolactic Fermentation?

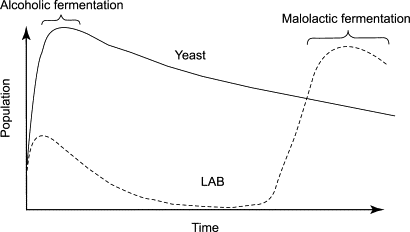

The process of malolactic fermentation (MLF) involves specific steps, including the preparation of the culture, inoculation of the beer with LAB, monitoring the fermentation progress, and ensuring its completion alongside the primary yeast fermentation.

Once the culture is prepared, it is crucial to ensure its viability and purity as it greatly influences the success of MLF. Inoculating the beer with lactic acid bacteria (LAB) requires careful consideration of timing and conditions to optimize their activity. Monitoring the fermentation progress involves regular sampling and analysis to track the reduction of malic acid and the production of lactic acid.

.jpg)

Concurrent management with the primary yeast fermentation involves maintaining suitable environmental conditions for both processes while preventing any detrimental interactions between the yeast and LAB populations.

Preparation of the Culture

The initial step in malolactic fermentation (MLF) entails the preparation of a suitable bacterial culture, ensuring the provision of essential nutrients and environmental conditions conducive to the growth and activity of lactic acid bacteria.

Creating an optimal environment for lactic acid bacteria (LAB) involves providing a nutrient-rich medium, typically containing complex nitrogen sources such as yeast extract or peptone, which serve as vital substrates for their growth and metabolism. Maintaining appropriate temperature and pH levels is crucial, as lactic acid bacteria thrive in mildly acidic conditions between 20-30°C.

The proper aeration of the culture plays a significant role in promoting their metabolic functions and enhancing MLF efficiency. These factors collectively are essential for successful bacterial culture preparation in MLF.

Inoculation of the Beer

Following the culture preparation, the next step in malolactic fermentation (MLF) involves the inoculation of the beer with specific lactic acid bacteria, typically facilitated by the introduction of specialized inoculants such as Acti-ML.

During the inoculation process, the specialized inoculants, like Acti-ML, play a crucial role in introducing the lactic acid bacteria into the beer, initiating the conversion of malic acid to lactic acid. This helps in reducing the acidity of the beer and enhancing its flavor profile.

The lactic acid bacteria (LAB) contribute to the fermentation process by metabolizing sugars to produce lactic acid and various other flavor compounds, influencing the overall character of the beer.

Monitoring the Progress

Throughout malolactic fermentation (MLF), diligent monitoring of the progress is essential, encompassing assessments of acidity reduction, diacetyl levels, and the overall transformation of malic acid into lactic acid by the bacterial strains.

Measuring the reduction in acidity levels during MLF is crucial as it provides insights into the metabolic activities of lactic acid bacteria. Similarly, monitoring diacetyl presence is vital to ensure the production of desirable flavors and aromas in the wine.

Tracking the conversion of malic acid into lactic acid serves as a key indicator of the progression of MLF, impacting the overall quality and characteristics of the wine. Utilizing advanced analytical techniques and meticulous record-keeping are essential components of effective fermentation monitoring.

Completion of Fermentation

The final phase of malolactic fermentation (MLF) involves ensuring the completion of the process, often requiring measures to stabilize alcohol levels, manage sulfur dioxide (SO2) presence, and mitigate any potential off-flavors or spoilage risks.

During the finalization of malolactic fermentation (MLF), winemakers carefully monitor and adjust alcohol levels to achieve the desired balance. This can involve techniques such as cold stabilization or the use of additives to control the alcoholic content.

The management of sulfur dioxide (SO2) is crucial in MLF, as it impacts microbial activity and can affect the overall quality of the wine. Winemakers need to precisely control the SO2 concentrations to facilitate MLF while avoiding undesirable effects.

What Are the Factors That Affect Malolactic Fermentation?

Several factors exert a significant influence on malolactic fermentation (MLF), including temperature, pH levels, and the availability of essential nutrients, all of which shape the viability and efficiency of the fermentation process.

Temperature plays a crucial role in MLF as it directly impacts the rate of bacterial activity. Higher temperatures can accelerate the process but may also lead to the production of undesirable by-products. Conversely, lower temperatures can slow down MLF, prolonging the fermentation period.

pH levels also significantly influence the progression of MLF, with an optimal range of 3.1 to 3.5 favoring bacterial activity.

The availability of nutrients such as nitrogen and vitamins is essential for the health and proliferation of malolactic bacteria, directly impacting the efficiency of the fermentation process.

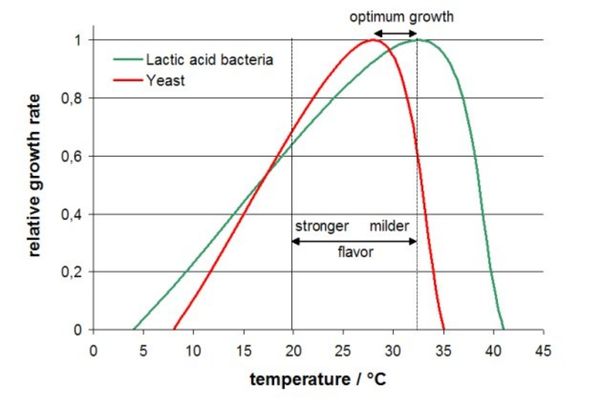

Temperature

The control of temperature is crucial in malolactic fermentation (MLF), as it directly influences the metabolic activities of lactic acid bacteria and mitigates microbial competition during the fermentation process.

Temperature control plays a pivotal role in creating a favorable environment for lactic acid bacteria to thrive and carry out the conversion of malic acid to lactic acid, adding desirable smoothness to the wine.

It helps regulate the population dynamics of microorganisms, preventing the dominance of undesirable strains and ensuring the dominance of the desired lactic acid bacteria. This control also assists in the preservation of the wine’s sensory characteristics and stability, ultimately affecting its quality and aging potential.

pH Level

The pH level plays a critical role in malolactic fermentation (MLF), influencing the acidity, stability, and overall progression of the fermentation process, thereby affecting the sensory attributes and preservation of the final product.

This delicate balance of pH levels directly impacts the conversion of malic acid to lactic acid by MLF bacteria, as higher acidity can inhibit or slow down the process, while a well-regulated pH level promotes a smoother and steady fermentation.

PH levels influence the stability of the wine, with low pH levels aiding in microbial stability and preventing spoilage. The impact of pH on fermentation dynamics and sensory outcomes underscores the crucial role it plays in shaping the characteristic flavor profiles and mouthfeel of the finished wine.

Nutrient Availability

The availability of essential nutrients is pivotal in malolactic fermentation (MLF), as it governs the vitality and competitive edge of lactic acid bacteria, directly impacting the efficiency and outcomes of the fermentation process.

Nutrient availability is fundamental to the overall health and vigor of lactic acid bacteria, facilitating their robust growth and sustained activity during MLF. This assures their competitive advantage over undesired microorganisms, promoting a favorable environment for the fermentation to progress.

Adequate nutrient supply directly correlates to the fermentation efficiency, influencing the rate and completeness of malic acid conversion to lactic acid, which is crucial for enhancing the organoleptic characteristics of the wine.

Presence of Oxygen

The presence of oxygen can significantly influence malolactic fermentation (MLF), as it may impact the stability of the fermentation process and contribute to potential risks of spoilage or sensory degradation in the final product.

When oxygen is present during MLF, it can lead to an increase in acetic acid production, which may have a negative impact on the sensory attributes of the wine. The presence of oxygen can promote the growth of spoilage microorganisms, potentially leading to off-flavors and aromas in the finished product. Oxygen exposure during MLF can also result in the depletion of sulfur dioxide, a key preservative, thereby reducing the shelf-life and stability of the wine.

How Can You Control Malolactic Fermentation in Beer?

The control of malolactic fermentation (MLF) in beer can be achieved through various strategies, such as the use of sulfites, malolactic inhibitors, and the meticulous monitoring and adjustment of temperature and pH levels during the fermentation process.

Controlling MLF in beer is crucial for achieving the desired flavor profile and stability in the final product. Sulfites, such as potassium metabisulfite, are commonly utilized to inhibit the growth of MLF bacteria and prevent unwanted fermentation. The use of malolactic inhibitors, such as lysozyme, can further suppress the activity of lactic acid bacteria, ensuring the retention of desired characteristics in the beer.

The careful management of temperature and pH during fermentation plays a pivotal role in controlling MLF. By maintaining optimal temperatures and pH levels, brewers can regulate the activity of MLF bacteria, minimizing the risk of uncontrolled fermentation and off-flavors in the beer. Understanding the interplay between these factors allows for the precise control of MLF, ultimately contributing to the consistent quality of the beer.

Use of Sulfites

The use of sulfites serves as an effective means to control malolactic fermentation (MLF) in beer, contributing to improved stability and mitigating potential risks of spoilage associated with uncontrolled bacterial activities.

Sulfites play a crucial role in inhibiting the growth of lactic acid bacteria, which are responsible for MLF in beer. By arresting the bacterial activity, sulfites help maintain the desired flavor profile and prevent the development of off-flavors. The application of sulfites aids in enhancing the stability of the beer by preventing oxidation and protecting it from the detrimental effects of spoilage organisms. Through these mechanisms, sulfites contribute significantly to the overall quality and shelf-life of the beer product.

Use of Malolactic Inhibitors

Malolactic inhibitors offer a targeted approach to controlling malolactic fermentation (MLF) in beer, effectively managing the metabolic activities of lactic acid bacteria and mitigating microbial competition during the fermentation process.

By utilizing malolactic inhibitors, brewers can influence the specific metabolic pathways involved in MLF, thereby exerting a significant impact on the growth and metabolism of lactic acid bacteria. This targeted control of bacterial activity not only shapes the flavor profile of the beer but also influences the overall fermentation dynamics. The strategic deployment of these inhibitors can modulate the competitive interactions between different microbial species, ultimately leading to a more predictable and stable fermentation process.

Monitoring and Adjusting Temperature and pH

The meticulous monitoring and adjustment of temperature and pH levels play a pivotal role in controlling malolactic fermentation (MLF) in beer, allowing for strategic intervention and management of the fermentation process.

In the context of malolactic fermentation, closely tracking and fine-tuning the temperature and pH of the fermentation environment are critical practices. These parameters influence the activity of lactic acid bacteria, impacting the speed and thoroughness of MLF.

By maintaining optimal temperature and pH levels, brewers can modulate the fermentation dynamics to achieve desired flavor profiles and mouthfeel in the final beer product. It’s crucial to integrate these monitoring and adjustment procedures into the broader fermentation management strategy, as they directly impact the outcome of the fermentation process.

What Are the Potential Risks of Malolactic Fermentation in Beer?

.jpg)

While malolactic fermentation (MLF) offers numerous benefits, it also poses potential risks, including the development of off-flavors and aromas, over-attenuation, and the risk of microbial contamination during the fermentation process.

Off-flavors and aromas can significantly alter the intended flavor profile of the beer, leading to undesirable taste experiences for consumers. Over-attenuation, on the other hand, can result in a reduction of body and mouthfeel, impacting the overall sensory characteristics of the final product.

The risk of microbial contamination during MLF can lead to spoilage, affecting the quality and shelf-life of the beer.

Off-Flavors and Aromas

Malolactic fermentation (MLF) can introduce the risk of off-flavors and undesired aromas in beer, particularly when microbial competition or suboptimal fermentation conditions lead to sensory degradation or spoilage issues.

These off-flavors may manifest as buttery or nutty notes, often associated with the presence of diacetyl or acetic acid. The competition between lactic acid bacteria and other microorganisms during MLF can result in the production of compounds that contribute to off-flavors.

Factors such as temperature fluctuations, lack of proper nutrients, or high alcohol content can also impact the success of MLF and potentially lead to the formation of undesirable aromas in beer.

Over-attenuation

Over-attenuation represents a notable risk associated with malolactic fermentation (MLF) in beer, as excessive fermentation activity may lead to unbalanced acidity levels and compromised stability in the final product.

.jpg)

When malolactic fermentation (MLF) progresses too far, the resulting decrease in acidity can have detrimental effects on the beer’s sensory attributes, potentially leading to an excessively flat or dull flavor profile.

Over-attenuation can impact the stability of the beer, compromising its shelf life and overall quality. It’s essential for brewers to closely monitor the progression of MLF to prevent over-attenuation and maintain the desired balance of acidity and stability in the finished product.

Risk of Contamination

The risk of microbial contamination represents a significant concern in malolactic fermentation (MLF) in beer, as uncontrolled microbial activities may lead to spoilage and sensory degradation in the final product.

Microbial contamination during MLF poses a potential threat to the quality of the beer, as it can introduce harmful microorganisms that might alter the flavor, aroma, and overall characteristics of the beverage. The presence of unwanted microbes could result in off-flavors and off-odors, impacting the consumer experience and potentially leading to product rejection.

This emphasizes the critical need for stringent monitoring and control measures to mitigate the risk of microbial contamination during MLF and ensure the production of high-quality beer.

Frequently Asked Questions

Why is malolactic fermentation used in beer making?

Malolactic fermentation is commonly used in beer making to reduce the acidity level in the beer and to create a more complex and rounded flavor profile.

What types of beer benefit from malolactic fermentation?

Malolactic fermentation is commonly used in beers where malic acid is present, but lactic acid bacteria may also be added along with malic acid to lagers, stouts, and barrel-aged beers to create a more mellow sour taste.

How is malolactic fermentation different from primary fermentation?

Primary fermentation is the initial stage of fermentation where yeast converts sugars into alcohol, while malolactic fermentation is a secondary process that occurs after primary fermentation and involves a different type of bacteria converting malic acid into lactic acid.

What are the benefits of malolactic fermentation in beer?

Malolactic fermentation can help to improve the mouthfeel of beer by reducing harsh acidic flavors, add complexity to the flavor profile, and increase the shelf life of the beer.

Is malolactic fermentation necessary in all beers?

No, malolactic fermentation is not necessary in all beers. It is typically used in styles that have higher levels of acidity and can benefit from a smoother flavor profile, but it is not essential for all beer styles.

-recipe.jpg)

Leave a Reply

You must be logged in to post a comment.