As a passionate brewer, I’ve always been intrigued by the diverse flavor profiles that can be achieved in beer making. Whether you’re a seasoned homebrew enthusiast or just starting out, understanding how to manipulate the sweetness in your beer can be a game-changer.

Sweetness in beer not only balances bitterness but can also enhance the overall flavor complexity, making your brew stand out.

In this blog, I’ll share seven tried-and-true methods I’ve used to increase the sweetness in my beer recipes, perfect for those looking to experiment with different taste profiles or create something unique for their palate.

1. Choose Malt Varieties with Higher Residual Sugars

Malt is the soul of beer, and its type and treatment can significantly affect the sweetness. Using malt varieties that have higher levels of unfermentable sugars can naturally increase the sweetness.

For example:

- Crystal or Caramel Malts: These malts undergo a special process where the sugars are crystallized, leading to higher residual sugars.

- Munich or Vienna Malts: These are slightly kilned and add a malty sweetness.

Certainly! Understanding the different types of malts and what makes them contribute to the sweetness in beer is crucial for any brewer looking to craft a beverage with a specific flavor profile.

Here’s a deeper dive into the world of sweet malts:

Malt Types and Their Contribution to Sweetness

1. Crystal or Caramel Malts

- Process: These malts are made by soaking the grains in water and then heating them. The process allows the starches to convert to sugars inside the grain, which are then caramelized during kilning.

- Flavor Contribution: They contribute a range of flavors from light caramel to deep toffee, depending on the degree of kilning.

- Sweetness: The crystallization process traps some sugars in a form that yeast cannot ferment, thus adding sweetness to the beer.

- Usage Tips: Use sparingly as they can dominate the beer’s flavor profile. A range from light to dark crystal malts can be chosen depending on the desired color and flavor intensity.

2. Munich and Vienna Malts

- Process: These malts are kilned at slightly higher temperatures than pale malts, which develops more malt flavors.

- Flavor Contribution: They impart a rich, malty sweetness with notes of bread, nuts, and a toasty character.

- Sweetness: The kilning process develops non-fermentable sugars that add a perceived sweetness to the beer.

- Usage Tips: Great for adding depth and complexity in lagers and ales, especially in Amber and darker beers.

3. Honey Malt

- Process: Honey malt is a type of pale malt that’s kilned in a way to develop a sweet, honey-like flavor.

- Flavor Contribution: As the name suggests, it imparts a sweet, honey-like taste and aroma.

- Sweetness: The unique kilning process enhances the malt’s natural sweetness, making it a popular choice for adding a sweet character to beers.

- Usage Tips: Use in moderation as it can easily overpower other flavors. Works well in lighter beers where its unique sweetness can shine through.

4. Special B Malt

- Process: This is a type of Belgian dark malt that undergoes a specific roasting process.

- Flavor Contribution: It imparts rich flavors of dark fruit, chocolate, and caramel.

- Sweetness: While not sweet in the traditional sense, its flavor profile can add a perception of sweetness due to its rich, complex flavors.

- Usage Tips: Ideal for Belgian dark ales, stouts, and porters where a complex, dark fruit and caramel profile is desired.

5. Melanoidin Malt

- Process: This malt is kilned to develop melanoidins, which are flavor and color compounds.

- Flavor Contribution: Adds a rich maltiness with notes of toasted bread and a slight nuttiness.

- Sweetness: While not directly sweet, it contributes to the overall malt backbone and can enhance the perception of sweetness.

- Usage Tips: Useful for adding complexity and a fuller mouthfeel in beers like Märzens or Scottish ales.

Each of these malts brings its unique characteristics and levels of sweetness to beer. When crafting a sweeter beer, consider the following aspects:

- Flavor Profile: Choose malts that align with the flavor profile you’re aiming for in your beer.

- Balance: Balance the use of these malts with other ingredients to avoid overpowering sweetness.

- Experimentation: Don’t be afraid to experiment with different combinations to find the perfect blend for your brew.

Summing up:

| Malt Type | Processing Method | Flavor Contribution | Sweetness Level | Usage Tips |

|---|---|---|---|---|

| Crystal/Caramel | Starches converted to sugars in grain, then caramelized during kilning | Ranges from light caramel to deep toffee flavors | High (unfermentable sugars) | Use sparingly; great for color and flavor, but can dominate |

| Munich | Kilned at higher temperatures than pale malts | Rich, malty sweetness with notes of bread and nuts | Medium (non-fermentable sugars) | Adds depth in lagers and ales, especially Amber and darker beers |

| Vienna | Similar to Munich but lighter, kilned to develop more malt flavors | Malty sweetness with a toasty character | Medium (non-fermentable sugars) | Used in lighter beers for malty depth without excessive darkness |

| Honey Malt | Kilned to develop a sweet, honey-like flavor | Sweet, honey-like taste and aroma | High (natural sweetness) | Use in moderation; ideal for lighter beers where a distinct sweet character is desired |

| Special B | Belgian dark malt with specific roasting process | Rich dark fruit, chocolate, and caramel flavors | Low (perceived sweetness) | Perfect for Belgian dark ales, stouts, and porters with complex, dark fruit and caramel profile |

| Melanoidin Malt | Kilned to develop melanoidins (flavor and color compounds) | Rich maltiness, toasted bread, slight nuttiness | Low (enhances perceived sweetness) | Useful for adding complexity and fuller mouthfeel in Märzens or Scottish ales |

Understanding and utilizing these malts effectively can significantly enhance the sweetness and overall flavor complexity of your beer, making it not just a beverage but a sensory experience. Cheers to your brewing adventures!

2. Adjust Your Mash Temperature

The mash temperature plays a crucial role in the sweetness of your beer. A higher mash temperature (around 154-158°F or 68-70°C) leads to more unfermentable sugars, making the beer sweeter. This is due to the enzymes’ activity at these temperatures, which creates dextrins that yeast cannot fully ferment.

The Science Behind Mash Temperatures

- Lower Temperatures (around 145-149°F or 63-65°C): At these temperatures, the enzyme beta-amylase is more active. This enzyme breaks down starches into simpler sugars like maltose, which are easily fermentable by yeast. The result is a beer with a drier taste and less residual sweetness.

- Higher Temperatures (around 154-158°F or 68-70°C): Here, the enzyme alpha-amylase becomes more dominant. Alpha-amylase breaks down starches into larger sugar molecules like dextrins, which are less fermentable by yeast. This leads to more residual sugars in the final product, imparting a sweeter, fuller body to the beer.

Practical Tips for Homebrewers

- Precise Temperature Control: Use a reliable thermometer. Maintaining a consistent temperature during the mash is crucial for achieving the desired sweetness level.

- Stirring the Mash: Ensure even temperature distribution by stirring the mash regularly.

- Mash Duration: A longer mash at a higher temperature can maximize the production of unfermentable sugars. However, be mindful not to overdo it, as excessively long mashing can lead to undesirable flavors.

- pH Levels: The pH of the mash also influences enzyme activity. Aim for a pH range of 5.2 to 5.6 for optimal results.

- Experimentation: Don’t hesitate to experiment with different temperature ranges to find the perfect balance for your beer. Slight variations can lead to noticeable differences in the final product.

An Example to Illustrate

Let’s say you’re brewing an ale and you want it to have a noticeable sweetness. By mashing at a temperature of around 156°F (69°C), you’re encouraging the production of larger sugar molecules that the yeast won’t fully ferment. This process leaves more sweetness in the final beer compared to mashing at a lower temperature.

In summary, mastering the mash temperature is a fundamental aspect of brewing, particularly when aiming to enhance the sweetness of your beer. It’s a delicate balance, but with careful attention to detail and a bit of experimentation, you can significantly influence the taste and body of your beer, creating a brew that perfectly aligns with your desired flavor profile.

3. Utilize Non-Fermentable Sugars

Incorporating non-fermentable sugars is a direct way to add sweetness. These sugars, like lactose (milk sugar) or maltodextrin, are not fully processed by the yeast, thus retaining their sweetness. Lactose is commonly used in milk stouts, giving them their characteristic sweetness.

Common Types of Non-Fermentable Sugars

- Lactose (Milk Sugar):

- Characteristics: Lactose is a sugar found in milk that most brewing yeasts cannot ferment.

- Usage: It’s commonly used in milk stouts or sweet stouts, providing a creamy, sweet character.

- Consideration: Be aware that lactose can cause issues for lactose-intolerant individuals.

- Maltodextrin:

- Characteristics: Maltodextrin is a complex sugar that yeast cannot digest efficiently.

- Usage: It adds body and sweetness without the strong flavor that lactose might impart.

- Result: You get a smoother, fuller mouthfeel in your beer.

- Artificial Sweeteners:

- Types: Products like sucralose or stevia can be used.

- Usage: They are completely non-fermentable and can sweeten the beer without adding calories or affecting body.

- Consideration: Their taste can be different from natural sugars, so experimentation is key.

How to Use Non-Fermentable Sugars

- Amount and Timing:

- The amount of non-fermentable sugar to add depends on the desired level of sweetness and the beer style.

- Typically, these sugars are added during the boil, allowing them to dissolve completely.

- Taste Testing:

- It’s vital to taste your brew at different stages. Start with smaller amounts and adjust in subsequent batches based on your preference.

- Balance with Other Ingredients:

- Remember that sweetness should complement the other flavors in your beer.

- Balance is key – too much sweetness can overpower other subtle flavors.

Considerations

- Effect on Mouthfeel: Non-fermentable sugars can increase the body and mouthfeel of your beer. This can be desirable in styles like stouts but less so in lighter beers.

- Fermentation Impact: These sugars don’t get fermented, so they don’t contribute to alcohol content. Your beer may have a lower ABV than if you used fermentable sugars.

- Stability and Shelf Life: Adding non-fermentable sugars generally doesn’t impact the beer’s stability or shelf life. However, it’s important to ensure that your beer is fully fermented before bottling to avoid over-carbonation or bottle bombs.

In summary, using non-fermentable sugars is a reliable way to add sweetness to your beer without affecting the fermentation process significantly. It allows for creativity and can help in crafting a beer that stands out with its unique flavor profile.

4. Late Addition of Hops

The timing of adding hops can affect the beer’s sweetness. Late hop additions (in the last 5-10 minutes of the boil or during dry hopping) contribute less bitterness and more aroma, indirectly enhancing the perception of sweetness.

How Late Hop Additions Work

In traditional brewing, hops are usually added at the beginning of the boil. The longer hops are boiled, the more bitterness they impart due to the isomerization of alpha acids. However, when hops are added in the last 5-10 minutes of the boil, or even after the boil during the whirlpool stage, there is less time for these alpha acids to isomerize. Consequently, there’s less bitterness imparted to the beer.

Impact on Sweetness

While late hop additions don’t directly make the beer sweeter, they do play a significant role in the perceived sweetness. Since these additions contribute less bitterness, the balance of the beer shifts. A lower level of bitterness allows the malt’s sweetness to be more prominent, enhancing the perception of sweetness in the final product.

Aroma and Flavor Contributions

Late hop additions are predominantly used to maximize the aroma and flavor contributions of the hops. These additions release more of the essential oils from the hops, which are responsible for the aromatic and flavor characteristics. You get more of the floral, fruity, citrusy, or piney notes, depending on the hop variety used. This enhancement of aroma and flavor can create a sensation of sweetness, or at least a balance that leans away from bitterness.

Dry Hopping

Dry hopping is a method where hops are added to the beer during fermentation or after fermentation is complete. This technique doesn’t contribute to the beer’s bitterness but significantly boosts its aroma and flavor profile. The aromatic compounds from the hops can create a perception of sweetness or fruitiness, further balancing or even masking the beer’s bitterness.

Experimenting with Hop Varieties

Different hop varieties will impart different levels of bitterness, aroma, and flavor, even when added late. Experimenting with various hops can lead to discovering the perfect balance for your beer. For instance, hops like Cascade or Citra are known for their citrus and floral notes, which can complement the sweetness well.

Conclusion on Late Hop Additions

Late hop additions are a powerful tool in a brewer’s arsenal, particularly when aiming to enhance the perceived sweetness in beer. By reducing bitterness and amplifying aroma and flavor, these additions can shift the balance of your beer, making the malt profile more pronounced. Experimenting with different hop varieties and timing can lead to a range of outcomes, offering a wide canvas for creativity in brewing sweeter-tasting beers.

5. Control the Fermentation Process

Controlling the fermentation process is crucial. Using yeast strains that have lower attenuation (the degree to which yeast ferments the sugars) can leave more residual sugars. Additionally, fermenting at the lower end of the yeast’s temperature range can also result in a sweeter beer.

Here, we delve deeper into how yeast attenuation, sugar conversion, alcohol tolerance, final specific gravity (SG), and cold fermentation temperatures can work towards a sweeter beer.

Yeast Attenuation and Sugar Conversion

Yeast attenuation refers to the percentage of sugars that yeast converts into alcohol and CO2 during fermentation. Different yeast strains have varying levels of attenuation:

- High-attenuation yeasts convert a larger percentage of sugars, resulting in drier beers.

- Low-attenuation yeasts leave more residual sugars, thereby producing sweeter beers.

By choosing a yeast strain with lower attenuation, you can control the sugar conversion process, retaining more sweetness in your final product. For example, some English ale yeasts are known for their lower attenuation, lending a sweeter profile to the beer.

Alcohol Tolerance of Yeast

The alcohol tolerance of yeast is another factor to consider. Yeast strains differ in their ability to survive and ferment in higher alcohol environments. If a yeast’s alcohol tolerance is exceeded, fermentation may stop prematurely, leaving unfermented sugars which result in a sweeter beer. However, this needs to be carefully managed to avoid imbalances in flavor or incomplete fermentation.

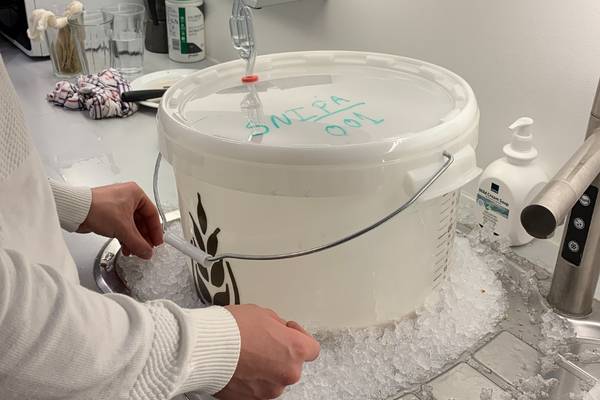

Fermenting cold

nother intriguing method to impact the sweetness in your beer is through cold fermenting. Fermenting at lower temperatures can play a significant role in the flavor profile of your brew. Lower temperatures generally slow down the fermentation process, giving you more control over the final product.

When you ferment colder, especially with certain yeast strains, the yeast tends to produce fewer esters and other flavor compounds, which can make the beer taste cleaner. Additionally, cold fermenting can sometimes result in a beer with more residual sugars, as the yeast is less active and doesn’t ferment all the sugars completely, leaving a slight sweetness behind.

This method is often used in styles like lagers, where a clean, crisp taste is desired with a subtle sweetness that balances the beer. However, it’s important to know your yeast’s temperature range and ensure that it can effectively work at lower temperatures. Experimenting with cold fermentation can be a fun and enlightening process, adding another dimension to your homebrewing skills.

Final Specific Gravity (SG)

Final SG is a measure of the density of the beer compared to water. A higher final SG often indicates more residual sugars, contributing to a sweeter taste. By monitoring the SG, you can gauge the extent of fermentation and decide when to halt it to maintain the desired sweetness level. Beers with final SG readings higher than 1.015 typically have a perceptible sweetness.

In summary, controlling the fermentation process for increased sweetness involves:

- Selecting a low-attenuation yeast strain to leave more residual sugars.

- Considering the yeast’s alcohol tolerance to manage the extent of fermentation.

- Fermenting cold.

- Monitoring the final SG to ensure the desired level of sweetness.

These techniques, when applied thoughtfully, can significantly influence the sweetness of your beer, offering you a canvas to craft a brew that truly resonates with your desired flavor profile.

6. Stopping Fermentation Prematurely

In line with the previous section, there are ways to prevent the yeast from using all the sugar.

Another method to consider for increasing the sweetness in your beer is stopping fermentation prematurely. This technique involves halting the fermentation process before all fermentable sugars are consumed by the yeast, thereby retaining a higher level of residual sweetness in the final product.

Here’s how you can do it:

Cold Crashing

One of the most common methods is cold crashing. This process involves cooling the beer to near-freezing temperatures (around 32-35°F or 0-2°C) for a few days. This sudden temperature drop causes the yeast to become dormant and settle at the bottom of the fermenter, effectively halting fermentation. While effective, it’s essential to note that cold crashing doesn’t kill the yeast, meaning fermentation could potentially resume if the beer warms up.

Chemical Additives

Another option involves the use of chemical additives like potassium sorbate and sodium metabisulfite. These chemicals don’t necessarily stop the yeast from fermenting but inhibit their ability to reproduce, thereby ceasing the fermentation process. It’s crucial to use these chemicals as per the recommended dosages and be aware that they can impart subtle changes to the flavor profile of your beer.

Pasteurization

A more advanced method is pasteurization, where the beer is heated to a temperature that kills the yeast. This method is commonly used in commercial brewing but can be tricky in a homebrew setting. It requires precise temperature control to avoid altering the flavor or quality of the beer.

Considerations and Risks

While these methods can be effective, they come with certain risks and considerations:

- Risk of Sweet/Unbalanced Beer: Prematurely stopping fermentation can lead to an excessively sweet or unbalanced beer, especially if not done carefully.

- Potential for Bottle Bombing: If you bottle a beer with active yeast and residual sugars, there’s a risk of overcarbonation, leading to bottle bombs.

- Altered Yeast Character: These methods can impact the natural character and complexity that yeast contributes to the beer.

Halting fermentation prematurely is a delicate process that can increase sweetness but requires caution and understanding of the risks involved. It’s a technique more suited for experienced brewers who are comfortable experimenting and taking the necessary precautions to ensure safety and quality.

Remember, brewing is an art of balance and patience, and sometimes the sweetest flavors come from allowing the process to unfold naturally.

7. Post-Fermentation Sweetening

Finally, you can sweeten your beer post-fermentation. This involves adding sweeteners like fruit syrups or artificial sweeteners after fermentation. However, be cautious with this method, as it can affect the beer’s stability and carbonation levels.

Types of Sweeteners

When it comes to post-fermentation sweetening, you have a variety of sweeteners to choose from. Each sweetener imparts its own unique flavor and characteristics to the beer:

- Fruit Syrups or Concentrates: These can add natural sweetness and fruity flavors. For instance, adding raspberry syrup can give a tart, sweet edge to your beer.

- Artificial Sweeteners: Sweeteners like sucralose or saccharin can sweeten the beer without being fermented by the yeast. They are calorie-free and do not contribute to the body or alcohol content.

- Natural Non-Fermentable Sugars: Honey, maple syrup, or molasses can add complex flavors along with sweetness. However, they need to be used carefully as they do also contain some fermentable sugars.

Considerations for Stability and Carbonation

When sweetening your beer post-fermentation, it’s crucial to consider the stability and carbonation of the final product:

- Preventing Re-Fermentation: If you are adding anything that contains fermentable sugars, there is a risk of re-fermentation. This can lead to over-carbonation or even bottle bombs. To prevent this, you can pasteurize the beer or use a yeast inhibitor.

- Carbonation: If you plan to bottle condition your beer, remember that the addition of non-fermentable sweeteners won’t contribute to the carbonation process. You’ll need to add priming sugar or use force carbonation methods.

Balance and Flavor Profile

The art of post-fermentation sweetening lies in achieving a balance that complements your beer’s flavor profile:

- Test and Adjust: Start with small additions and taste your beer. You can always add more sweetener, but it’s difficult to remove it once added.

- Harmonize with Beer Style: Consider the style of beer you’re brewing. Rich, dark beers might benefit from molasses or maple syrup, while lighter beers might be better suited to fruit syrups.

Practical Tips

Here are some practical tips to ensure success:

- Dissolve Sweeteners: If using granulated or solid sweeteners, dissolve them in a small amount of water to create a syrup before adding to your beer. This ensures even distribution.

- Sanitation: Ensure that any sweetener you add post-fermentation is properly sanitized to avoid contamination.

- Record Keeping: Always keep notes on how much sweetener you add and the resulting taste. This will help in replicating or adjusting in future batches.

Post-fermentation sweetening is a powerful tool in a brewer’s arsenal. It allows for a high degree of control and creativity in flavoring your beer. Whether you’re aiming for a subtle hint of sweetness or a rich, dessert-like profile, the key is to experiment and find the balance that works for your brew.

Conclusion

In summary, making your beer sweeter involves understanding and manipulating various brewing elements:

- Choose malt varieties with higher residual sugars like Crystal or Munich malts.

- Adjust the mash temperature to around 154-158°F for more unfermentable sugars.

- Experiment with specialty grains like honey malt for added sweetness.

- Incorporate non-fermentable sugars like lactose for direct sweetness.

- Opt for late hop additions to enhance the perception of sweetness.

- Control the fermentation process using specific yeast strains and temperatures.

- Consider post-fermentation sweetening with caution for additional sweetness.

Remember, brewing is as much an art as it is a science. Each method offers unique advantages and can be tailored to your brewing style and taste preferences. Happy brewing, and may your beers be as sweet as your successes! 🍻

FAQ Section

In this section, we’ll address some frequently asked questions that complement our main discussion on sweetening beer. These answers aim to cover additional queries that might arise when you’re experimenting with different ways to add sweetness to your brews.

Can Adding Sweetness Impact the Beer’s Shelf Life?

Shelf Life and Sweetness: Adding sweetness to beer, especially through non-fermentable sugars or post-fermentation methods, can impact its shelf life. Beers with higher sugar content can be more prone to oxidation or microbial contamination, which can shorten their shelf life. It’s important to ensure proper sanitization and storage conditions to maximize your beer’s longevity.

How Does Sweetness Affect Beer Pairing with Food?

Sweetness in Beer and Food Pairing: Beers with added sweetness can offer unique and delightful pairing opportunities with food. Sweeter beers tend to pair well with spicy dishes, as the sweetness can balance the heat. They also complement desserts nicely, especially those with caramel or chocolate flavors. However, it’s important to achieve a balance so that the sweetness in the beer does not overpower the flavors of the food.

Are There Any Health Considerations When Adding Sweeteners?

Health Considerations: When adding sweeteners, especially artificial ones, be mindful of potential health impacts. Some artificial sweeteners can have gastrointestinal side effects if consumed in large quantities. Additionally, for those with dietary restrictions or diabetes, it’s crucial to consider the type and amount of sweetener used in the beer.

Can Sweetness Levels Change During Bottle Conditioning?

Sweetness and Bottle Conditioning: During bottle conditioning, there might be slight changes in perceived sweetness. As the yeast consumes the priming sugar to produce carbonation, this can sometimes slightly dry out the beer, potentially reducing the sweetness a bit. However, these changes are usually minimal unless there’s unintended additional fermentation of added sweeteners.

Is It Possible to Reduce Sweetness in a Finished Beer?

Reducing Sweetness in Finished Beer: Reducing sweetness in a beer that’s already been fermented is challenging. One approach is to blend the sweeter beer with a drier, less sweet beer. This method allows for adjusting the flavor profile to achieve a more balanced taste. However, it requires careful experimentation and taste testing to get the right blend.

Leave a Reply

You must be logged in to post a comment.