Stuck fermentation is a common issue that many homebrewers face. It occurs when the yeast stops fermenting before all the sugars have been converted into alcohol.

This can result in a beer that is too sweet and has a low alcohol content. Restarting a stuck beer fermentation can be a challenging process, but it is possible with the right techniques and tools.

Understanding Stuck Beer Fermentation Stuck fermentation can occur for a variety of reasons, including low yeast cell count, high alcohol content, and low nutrient levels.

When yeast is stressed, it may stop fermenting altogether, leading to a stuck fermentation. It is important to understand the factors that can affect fermentation to prevent it from happening in the first place.

Key Takeaways:

- Stuck fermentation is a common issue that can result in a beer that is too sweet and has a low alcohol content.

- Several factors can affect fermentation, including temperature, pH levels, and nutrient levels.

- Troubleshooting stuck fermentation involves identifying the cause of the problem and taking steps to correct it.

Factors Affecting Fermentation Several factors can affect fermentation, including temperature, pH levels, and nutrient levels. Monitoring these factors and making adjustments as needed can help prevent stuck fermentation.

Troubleshooting stuck fermentation involves identifying the cause of the problem and taking steps to correct it. This may involve adding more yeast, adjusting the temperature, or adding nutrients to the beer.

Understanding Stuck Beer Fermentation

Stuck beer fermentation is a common problem that brewers face during the brewing process. It occurs when the yeast in the beer stops fermenting, resulting in a beer that is too sweet or too high in gravity. Understanding the reasons behind stuck beer fermentation can help brewers prevent it from happening and resolve it when it does occur.

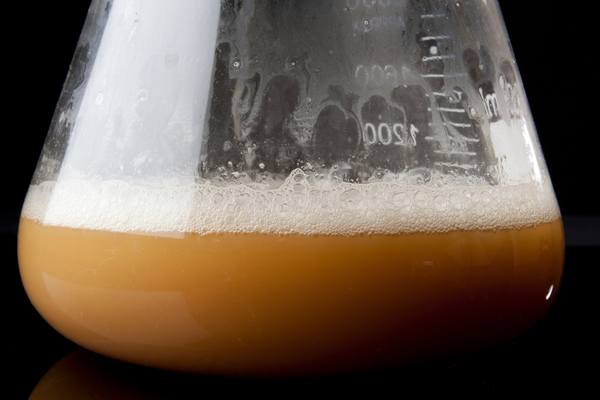

Fermentation is the process by which yeast converts the sugars in the beer wort into alcohol and carbon dioxide. During the fermentation process, the yeast consumes the sugars in the wort and produces alcohol and CO2.

The gravity of the beer decreases as the yeast consumes the sugars, and the final gravity is reached when the yeast has consumed all the available sugars.

The original gravity of the beer is the gravity of the wort before fermentation begins, and the final gravity is the gravity of the beer at the end of fermentation. Measuring the gravity of the beer using a hydrometer can help brewers determine the progress of fermentation.

When the yeast stops fermenting before it has consumed all the available sugars, the beer is said to be stuck. This can occur due to several reasons, including:

- Insufficient or unhealthy yeast

- Inadequate oxygenation of the wort

- High alcohol content in the beer

- High gravity wort

- Low temperature during fermentation

- Contamination of the beer

When a brewer encounters a stuck fermentation, it is essential to identify the cause and take corrective action. Restarting a stuck fermentation can be challenging, but it is possible. Brewers can try several methods to restart a stuck fermentation, including adding more yeast, increasing the temperature, and adding additional fermentable sugars to the wort.

In conclusion, understanding the causes of stuck beer fermentation and taking corrective action can help brewers prevent it from happening and resolve it when it does occur.

Measuring the gravity of the beer using a hydrometer can help brewers determine the progress of fermentation and identify potential issues. When a stuck fermentation occurs, brewers can try several methods to restart the fermentation and produce a high-quality beer.

Factors Affecting Fermentation

When it comes to beer fermentation, there are several factors that can affect the process. Here are some of the most important factors to consider:

Temperature Influence

Temperature is one of the most important factors affecting fermentation. The correct temperature range is essential for efficient fermentation and to achieve the desired character in the final product.

Room temperature is usually too low for fermentation, so it is important to maintain a consistent fermentation temperature within the correct range.

Low temperatures can cause fermentation to slow down or even stop, while high temperatures can cause off-flavors and other problems. Correct pitching temperature is also important to ensure the yeast cells are active and ready to ferment.

Yeast Influence

Yeast is a crucial component of beer fermentation. Using a fresh yeast sample or yeast cake is important to ensure that there are enough active yeast cells to ferment the wort. Yeast nutrient can also be added to the wort to provide the necessary nutrients for the yeast cells.

Choosing the right yeast strain is important for achieving the desired character in the final product. A yeast starter can be used to increase the number of yeast cells and ensure a healthy fermentation.

Nutrient and Oxygen Influence

Sugar and nutrients are essential for yeast growth and fermentation. Simple sugars such as sucrose and glucose are readily available for yeast to ferment, while nitrogen and other nutrients are also important for yeast health.

oxygen affect fermentation in brewing” class=”wp-image-946″/>

oxygen affect fermentation in brewing” class=”wp-image-946″/>Oxygen is also necessary for yeast growth in the beginning, but too much oxygen can cause off-flavors and other problems in late stage fermentation.

Supplements such as servomyces can be added to the wort to provide additional nutrients for yeast growth.

Equipment Influence

The equipment used for fermentation can also affect the process. A hydrometer can be used to measure the specific gravity of the wort and monitor fermentation progress. Properly sanitized equipment is important to prevent contamination and ensure a healthy fermentation. Tools such as a carboy or fermenter can be used for primary or secondary fermentation.

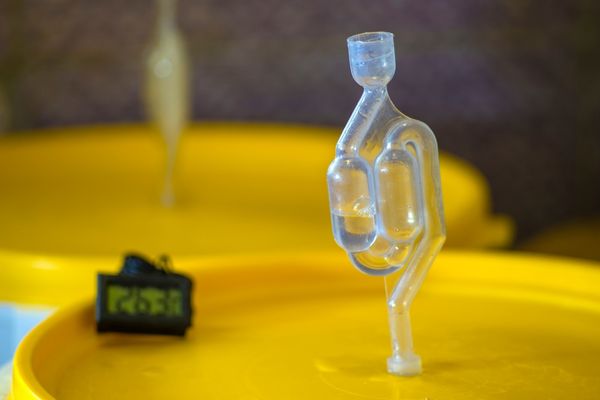

Pressure and Carbon Dioxide Influence

Pressure and carbon dioxide can also affect fermentation. An airlock can be used to release excess carbon dioxide during fermentation. A pressure gauge can be used to monitor the pressure inside the fermenter. Too much pressure can cause off-flavors and other problems, while too little pressure can cause carbonation issues.

Alcohol Influence

Alcohol tolerance is important for yeast strains used in beer fermentation. Some strains have a higher tolerance for alcohol than others. Monitoring the alcohol content during fermentation can help ensure that the yeast cells are healthy and active.

Troubleshooting Stuck Fermentation

When a beer fermentation gets stuck, it can be frustrating for a brewer. Fortunately, there are several techniques that can be used to restart the fermentation process. These techniques include rousing the yeast, adding nutrients and oxygen, adjusting temperature, and pitching fresh yeast.

Rousing the Yeast

One way to restart a stuck fermentation is to rouse the yeast. This involves gently stirring the beer to put the yeast back into suspension. By doing so, it can help to kickstart the fermentation process. Rousing the yeast can be done with a sanitized spoon or by gently swirling the fermenter.

Adding Nutrients and Oxygen

Adding yeast nutrient or yeast energizer can help to restart a stuck fermentation. These products contain essential nutrients that the yeast needs to thrive. Oxygenation can also help to restart a fermentation. By adding oxygen to the wort, it can help the yeast to reproduce and continue fermenting.

Adjusting Temperature

Fermentation temperatures can play a significant role in whether or not a fermentation gets stuck. If the temperature is too low, the yeast can become sluggish and stop fermenting. If the temperature is too high, the yeast can produce off-flavors or die off. By adjusting the temperature to the ideal range for the yeast strain being used, it can help to restart the fermentation.

Pitching Fresh Yeast

If all else fails, pitching a fresh batch of yeast can help to restart a stuck fermentation. It is important to use the right pitch rate to ensure that there are enough yeast cells to ferment the wort. Precision fermentation can help to ensure that the right amount of yeast is added to the beer.

It is important to note that a stuck fermentation can be caused by a variety of factors, including contamination, low yeast cell count, and pH issues. By troubleshooting the problem and using the appropriate techniques, it is possible to restart a stuck fermentation and save the batch of beer.

Prevention and Final Tips

Gravity and Hydrometer Accuracy

To prevent a stuck fermentation, it is important to take accurate gravity readings using a hydrometer. Gravity readings help to determine the progress of fermentation and whether it has stalled. It is essential to ensure that the hydrometer is calibrated correctly to ensure accurate readings.

Proper Yeast Management

Proper yeast management is crucial for a successful fermentation. It is essential to pitch the correct amount of yeast cells and to ensure that they are healthy and active. Using dried malt extract or a stir plate to create a yeast starter can help to ensure that there are enough viable yeast cells to complete fermentation.

Maintaining Correct Conditions

Maintaining the correct conditions throughout the fermentation process is also important. The temperature should be kept within the optimal range for the yeast strain being used. Krausen, the foam that forms on top of the fermenting beer, should be monitored to ensure that it is healthy and active. Krausening, the process of adding actively fermenting wort to the beer, can help to restart a stuck fermentation.

Avoiding Contamination

Contamination can also cause a fermentation to stall. It is essential to maintain a clean and sanitized environment throughout the brewing process. All equipment, including fermenters, airlocks, and tubing, should be thoroughly cleaned and sanitized before use.

By following these prevention and final tips, it is possible to avoid a stuck fermentation and ensure that the beer fermentation process is successful.

Leave a Reply

You must be logged in to post a comment.