Making a great hard cider requires more than just good ingredients and technique. Yeast plays an important role in the final product, as it helps to create both flavor and alcohol content during fermentation.

It can affect the taste, appearance, and alcohol percentage of your cider.

Taste is perhaps the most important factor, and the taste is a result of the brewing capabilities and metabolism of the yeast. Yeasts will convert different (more or less tasty) chemical compounds in the apple juice into other compounds, change the acid profile and remove sugars.

Additionally, temperature and alcohol range is an important factor when choosing a yeast strain as some strains may not be able to tolerate extreme temperatures, high alcohol or low pH levels during fermentation.

Also, flocculation ability (the ability for particles suspended in liquid to clump together) should be taken into account as this affects clarity and sediment formation during fermentation and aging processes.

Lastly, speed of fermentation should also be considered as certain strains ferment faster than others which could lead to over-fermentation if left unchecked.

In this article we’ll explore yeast in cider making – what it is, different types of yeasts used for cider brewing, how to choose the right one for your recipe and commercial yeasts available on the market today.

We will also cover best ciders yeasts for beginners through advanced brewers, whether beer or baking yeast can be substituted and if you can reuse existing cider yeast from batch to batch!

Best Yeast Strains for Cider Brewing

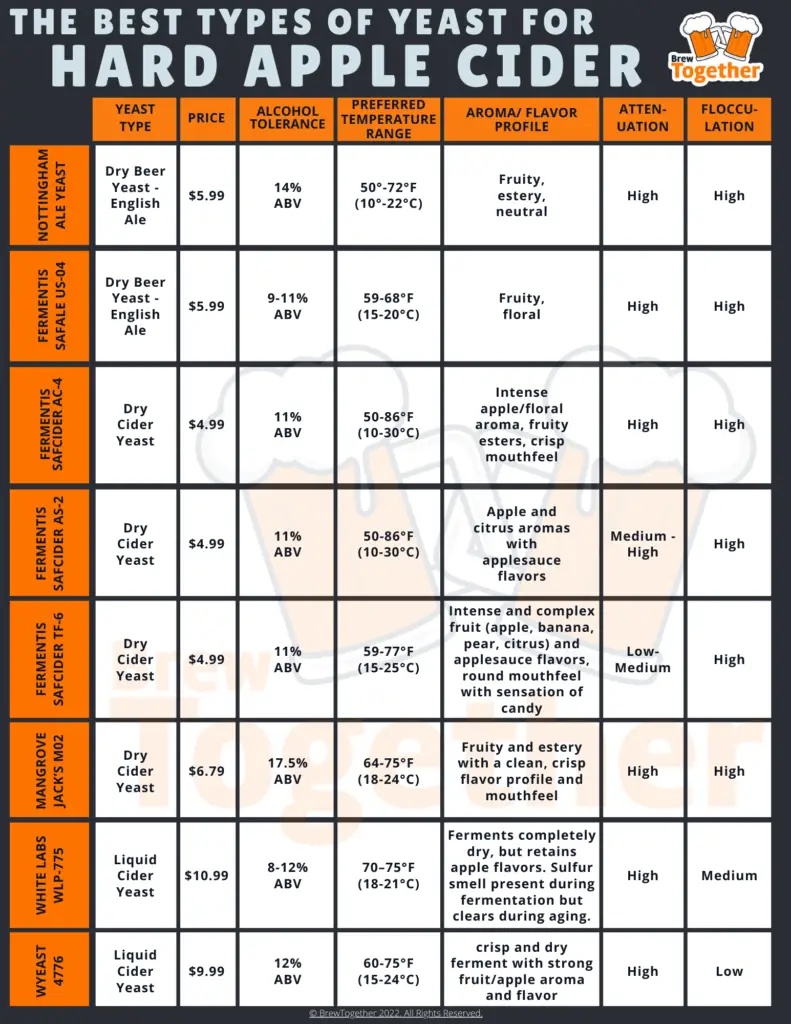

We know that the yeast you choose can make all the difference when it comes to brewing hard cider. That’s why we’ve put together a list of the best yeasts for hard cider brewing.

Our list includes popular strains like:

- Mangrove Jacks’s M02

- Fermentis SafCider yeasts

- Lavin EC-118 yeast

- Red Star Premier Blanc Champagne Yeast

- Red Star Premier Classique Wine Yeast

- Cider House Select Cider Yeast

- Safale S-04

- and the more premium White Labs WLP001 wet yeast.

We’ve tested and researched each of these yeasts extensively (read about our experiment below), but why not try them out in small batches for yourself?

What Does Yeast Do for Your Cider?

When it comes to cider making, yeast is key. This microorganism is responsible for fermenting the apple juice and turning it into delicious cider.

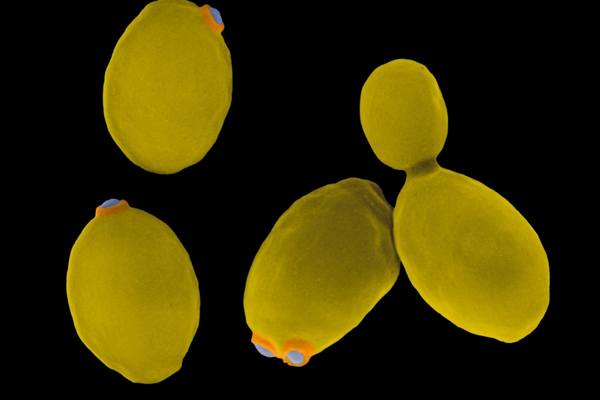

Yeast is a single-celled microorganism that plays an essential role in the production of alcoholic beverages, including cider. It’s responsible for converting sugar into alcohol and carbon dioxide during fermentation.

The type of yeast used will affect e.g. the flavor, aroma, and fermentation rate of the cider.

Because the type of yeast you use will determine the final flavor of your cider, be sure to choose one that matches your desired taste profile.

Managing the fermentation process can be tricky – pH levels and temperatures play a big role in how successful (or not) your batch will be.

Common problems like infection, overfermentation, and off flavors can all occur if things aren’t kept under control. That’s why understanding what yeast does during each stage of cider production is essential for any home brewer.

By being aware of potential pitfalls – and taking steps to avoid them – you’ll increase your chances of making a great-tasting batch every time.

Main Takeaway: Managing the fermentation process is tricky – pH levels and temperature in combination with the yeast strain play a big role in how successful (or not) your batch will be.

What Factors to Consider When Choosing a Yeast for Cider

When it comes to choosing a yeast for cider, there are several factors that you need to take into account in order to end up with a finished product that you’re happy with. The first thing to consider is what kind of flavor profile you’re going for.

Different yeasts will produce different flavors, so if you have a specific taste in mind, make sure to choose a yeast that will complement the other ingredients in your cider. Another important factor is alcohol content.

If you want your cider to be on the stronger side, look for a yeast that has high attenuation rates (this means it converts more sugar into alcohol).

Conversely, if you prefer something on the lighter, sweeter, side, go for a lower attenuation rate.

Most yeasts says some percentage on the package indicating how high an alcohol volume it can add to the cider, but this of course depends on the sugar content to begin with! It also depends on acidity, nutrients available, the apple type and especially the temperature!

Finally, pay attention to flocculation and fermentation temperature when selecting your yeast strain.

Flocculation refers to how well the yeast clumps together and falls out of suspension; higher flocculating yeasts will drop out of solution faster than low-flocculating ones.

As far as fermentation temperature goes, each strain has its own ideal range; fermenting outside of this range can result in off-flavors or inhibited fermentation altogether.

Keeping all of these factors in mind should help ensure that you choose the best possible yeast for your next batch of cider!

Main Takeaway: When choosing a yeast for cider, mainly consider the flavor profile you’re going for and the alcohol content you want. The desired clarity and temperature range are also worth considering, but are usually secondary.

The Different Strains of Yeasts Used in Cider Making

When it comes to making cider, there are several different types of yeasts that can be used in order to get the desired taste and fermentation process.

There are many different strains of yeast used in brewing, including:

- Saccharomyces cerevisiae: This is a species of yeast commonly used in the production of ale, lager, and other types of beer. It is known for its ability to ferment sugars into alcohol and produce a wide range of flavors and aromas.

- Saccharomyces pastorianus: This is a species of yeast that is often used in the production of lager-style beers. It is known for its ability to ferment sugars into alcohol and produce a clean, crisp flavor.

- Saccharomyces bayanus: This is a species of yeast that is commonly used in the production of champagne and sparkling wines. It is known for its ability to ferment sugars into alcohol and produce a high level of carbonation.

- Brettanomyces: This is a genus of yeast that is often used in the production of lambic-style beers and other wild ales. It is known for its ability to produce a wide range of flavors and aromas, including barnyard, horse blanket, and tropical fruit.

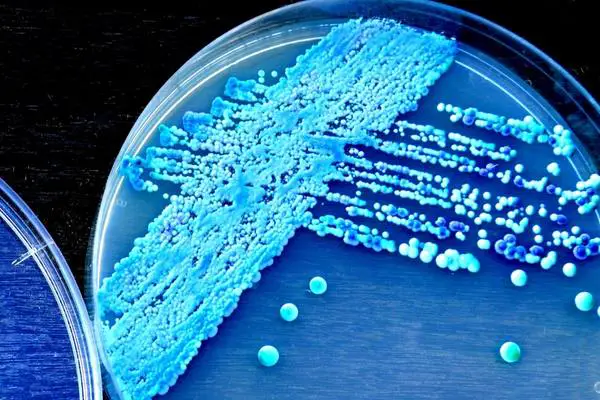

In addition, the following bacterial strains may be used e.g. in malolactic fermentation or sour beers:

- Lactobacillus: This is a type of bacteria that is commonly used in the production of sour beers. It is known for its ability to convert sugars into lactic acid, which gives these beers their sour flavor.

- Pediococcus: This is another type of bacteria that is commonly used in the production of sour beers. It is known for its ability to convert sugars into lactic acid, which gives these beers their sour flavor.

But for hard cider specifically, the most common species of yeast used is Saccharomyces cerevisiae, which is a general purpose brewing yeast used in many wines, champagne and ciders.

The most popular yeasts for cider making will tend to resemble those also used in wine and champagne making more than that of beer brewing.

Wine Yeast:

Wine yeast is a popular choice among home cider brewers because it produces fairly clean flavors without any off notes or funky aromas.

This type of yeast works best at cooler temperatures (between 60-75°F) and will usually take longer than other varieties to complete fermentation – usually around two weeks!

It’s important to keep an eye on your fermentations when using wine yeast as it can easily become stuck if left unchecked for too long.

Champagne Yeast:

Champagne yeast is known for its ability to produce high levels of alcohol quickly—upwards of 15% ABV! However, this type of yeast has a tendency towards producing harsh flavors if not monitored closely during fermentation.

Therefore, champagne yeasts should only be used by experienced brewers who know how to manage their ferments properly.

Additionally, champagne yeasts require warmer temperatures (70-80°F) in order for them work effectively so make sure you have adequate temperature control before attempting this variety!

Cider Yeast:

Cider specific strains are designed specifically with cider makers in mind and offer distinct advantages over traditional beer or wine varieties such as faster fermentations times (3-5 days) and lower final gravity readings due their increased flocculation abilities meaning less residual sugar remains after fermentation has completed leading dryer end results overall!

Cider specific strains also tend towards fruity esters which help bring out the natural sweetness from the apples being fermented adding complexity and depth beyond what regular beer/wine yeasts could provide alone!

Wild Yeasts:

Wild yeasts are naturally occurring microorganisms found on the skins of apples or other fruits used in cider-making. These wild yeasts can add complexity and depth to your ciders, but they can also be unpredictable and difficult to control. It’s important to note that some wild yeasts may produce off flavors or even spoilage if not managed properly.

However, wild yeasts such as Brettanomyces bruxellensis and Hanseniaspora uvarum are naturally found on most apples and can (if not sulfites are added, that is!) also add tartness and wine notes respectively to the cider.

Bruxellensis is commonly known as “wild” or “spontaneous” yeast due its ability to spontaneously ferment sugars into alcohol without any additions required like cultivated yeasts (Saccharomyces).

This characteristic makes this strain ideal for producing traditional Lambic style beers or ciders where wild organisms present in the air contribute towards fermentation over time resulting in a more complex, sour and wine-like, flavor profile with earthy funkiness.

Hanseniaspora uvarum on the other hand ferments at relatively lower temperatures when compared Saccaramyces strains while still being able produce high levels of CO2 gas.

This particular trait allows for fruity esters development during secondary fermentation stage under anaerobic conditions similarily found in winemaking grape juice turning them into wines.

These characterstics give Hanesniaspora-fermented products well balanced acidity along with sweetness leading often times crisp dry finishings.

I isolated my own Hanesniaspora strain from my local apples, and I have used it numerous times in conjunction with a timely cold crashing technique to obtain a fruity and sweet wine-like cider!

Beer Yeast:

Beer yeasts are typically used by commercial breweries but can also be utilized by homebrewers looking for more complex flavor profiles from their ciders.

Beer yeasts are numerous, but not commonly used in cider, which is a shame, as there are indeed many to explore and experiment with!

Some popular beer yeasts include:

- Ale yeasts, such as Safale S-04, White Labs WLP001 (California Ale Yeast), and Wyeast 1056 (American Ale Yeast)

- Lager yeasts, such as Saflager S-23, White Labs WLP830 (German Lager Yeast), and Wyeast 2007 (Pilsen Lager Yeast)

- Hefeweizen yeasts, such as White Labs WLP300 (Hefeweizen Ale Yeast) and Wyeast 3638 (Bavarian Wheat Yeast)

- Belgian yeasts, such as White Labs WLP500 (Monastery Ale Yeast) and Wyeast 1214 (Belgian Ale Yeast)

- Wheat beer yeasts, such as White Labs WLP380 (Hefeweizen IV Ale Yeast) and Wyeast 3333 (German Wheat Yeast)

- Saison yeasts, such as White Labs WLP565 (Belgian Saison I Yeast) and Wyeast 3711 (French Saison Yeast)

- Fruit beer yeasts, such as White Labs WLP644 (Brettanomyces bruxellensis Trois) and Wyeast 5112 (Brettanomyces lambicus)

These strains tend towards higher attenuation levels which means they will consume more sugars during fermentation resulting in drier finished products with higher alcohol content (8-10% ABV).

They also work well at cooler temperatures (60-68°F), making them ideal choices for those living in colder climates where maintaining consistent warmth isn’t always possible!

In short, depending on what type of characteristics you want your final product have will determine which strain(s)of yeast you use during Fermentation. But don’t let all these talk about scientific terms scare you off!

In reality choosing correct one isn’t difficult task knowing basic guidelines detailed above…So go out their experiment until find perfect combination that suits your personal preference!

Main Takeaway: Different types of yeast will produce different flavors in cider. Traditional cider yeasts, champagne yeast and wild yeast are most often used in cider fermentations.

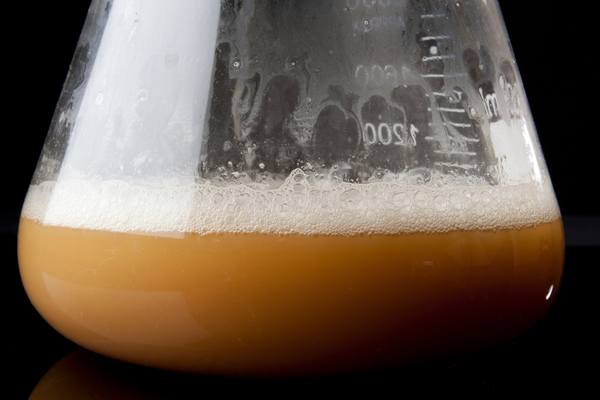

Choosing the Best Cider Yeast: Lessons from a Small Scale Experiment

When it comes to crafting a memorable cider, the character of your brew often begins with the yeast. Recently, I decided to put this to the test by experimenting with 10 different dried yeast strains and one natural fermentation.

The process was as educational as it was flavorful, and I learned quite a bit about how different yeasts influence the final product. Here’s a detailed breakdown of my experience.

The Experiment Setup

For this experiment, I used pure Dabinett apple juice, known for its rich tannins and cider-friendly qualities. All batches were fermented in the coldest part of my house, which I estimate stayed around 15°C (59°F). Some were one-gallon batches, while others were five gallons. Minimal sulphiting was used, following the guidelines from Andrew Lea’s book on cider-making.

The dried yeasts I tested were:

- QA23

- 71B

- D47

- California Lager Yeast

- S04 (English Ale Yeast)

- M42 (New World Strong Ale Yeast)

- M02 (Cider Yeast)

- Nottingham

- M44 (US West Coast Yeast)

- M15 (Empire Ale Yeast)

In addition, I tried a natural fermentation batch. While I can’t recall if I sulphited this one, I know the rest were prepared with care to ensure consistent conditions.

The Results

After racking the batches and sampling each one, I found the natural fermentation, QA23, 71B, and D47 stood out by a long shot. Here are some key observations:

- Natural Fermentation

This batch was the most surprising. Despite being less controlled, it retained a lot of residual sugar (finishing at SG 1.020) and delivered a complex, almost wild flavor. It was cloudy but packed with character. - Lalvin QA23, 71B, and D47

These wine yeasts consistently produced vibrant, flavorful ciders. QA23 brought a delicate fruitiness, 71B accentuated the apple’s natural sweetness, and D47 added body and richness. Their finishes were clean, ending around SG 1.005, and they balanced tannins well. - Ale and Lager Yeasts

The ale and lager yeasts were crystal clear and almost polished in appearance, but many lacked depth. S04, which I’ve loved in ale brewing for over 20 years, felt neutral and insipid when used with apple juice. M42 and M15 fared slightly better, but they didn’t bring the complexity I was hoping for. - M02 (Cider Yeast)

As a cider-specific yeast, M02 emphasized tannins and astringency. While this could be desirable in some contexts, the flavor profile felt unbalanced compared to the wine yeasts. - Nottingham and M44

These yeasts produced decent ciders but leaned toward neutrality. They didn’t bring any unpleasant characteristics, but they also didn’t stand out.

Key Takeaways

- Natural Fermentation: This was a revelation. While risky due to the lack of control, it resulted in a beautifully unique cider with complex flavors.

- Wine Yeasts: QA23, 71B, and D47 were clear winners. These yeasts enhanced the natural qualities of the apples and produced ciders with depth and character. I’m glad I used these for the larger batches.

- Ale and Lager Yeasts: While some brewers may appreciate the clarity and subtlety of these yeasts, they didn’t shine in this experiment. They felt too clean and lacked the boldness I wanted.

Reflections and Tips

Would I do this experiment again? Probably not. It was a lot of work, but it gave me valuable insights. If I were to recommend yeasts for cider-making, I’d suggest starting with QA23, 71B, or D47, especially if you’re aiming for a flavorful, well-rounded cider. Natural fermentation is also worth exploring if you’re willing to embrace some unpredictability.

Some commenters on my experiment shared their own experiences, which added even more depth to my findings. For example:

- One brewer noted that S04 can produce fruity notes if fermented at warmer temperatures, which might explain why mine felt muted at 15°C.

- Another shared their success with natural fermentation methods, using a ginger beer plant as a starter culture for strong and consistent results.

- A recommendation for Lalvin EC-1118 for colder fermentations is something I’d like to try in the future.

This experiment reaffirmed my belief that yeast choice plays a pivotal role in cider-making. Each yeast imparts unique qualities, so understanding their characteristics can help you achieve the flavor profile you’re after. If you’ve had success (or failure!) with other yeasts, I’d love to hear about your experiences. Cheers to crafting the perfect cider!

What Are the Best Commercial Yeasts Available?

Commercial yeasts specifically designed for making hard cider are available from many homebrew suppliers online or at local stores specializing in home brewing supplies.

Scroll to the end of this article to see a complete table of the 20 most popular yeasts available to home brewers and their stats!

These come pre-measured in small packets or jars that contain enough yeast cells needed for 5 gallons (19 liters) of juice – usually around 100 billion cells per gram depending on the strain chosen – so there’s no need to worry about measuring out individual doses yourself when using these products.

The process of fermentation is key to many beloved alcoholic beverages. The right yeast can make all the difference in terms of flavor, aroma, and mouthfeel.

But with so many commercial yeasts on the market, it can be hard to know where to start.

Here are five of the best commercial yeasts available for making beer, wine, cider, champagne, and more:

1. White Wine Yeast – For a classic and clean fermenting experience that will produce dry wines with good acidity levels, try:

Lalvin Premier Blanc Champagne Yeast or Red Star Premier Classique Wine Yeast.

Both are great options for cider making as they ferment with a clean taste and precipitate nicely when done to clear the cider.

2. Champagne Yeast – Numerous options for a strongly carbonated cider.

Try using a true champagne yeast like Lavin EC-118, Red Star or Moreau & Fils Cuvée Spéciale Crémant de Loire Brut Nature. These strains are designed specifically for producing sparkling wines and champagnes with plenty of fizziness and complexity.

Especially the Lalvin EC-1118 is great for most high alcohol and champagne-like ciders with a dry but clean and smooth acidic finish.

I have used it many times for my hard-to-ferment juices and to restart stuck fermentations.

3. Beer Yeast – There are Many Different Strains of Beer Yeast Available on the Market, So It Really Depends on What Style of Beer You’re Trying to Make.

For a traditional American ale, try White Labs WLP001 California Ale Yeast or Fermentis Safale US-05 Dry Brewing Yeast.

If you’re looking to brew a German lager, go with Weihenstephaner Hefeweissbier Dunkel or Wyeast Activator 1084.

They work especially well for hopped-cider varieties and those where malt has been added!

4. Cider Yeasts – The real deal!

Most cider makers are using a champagne yeast like Lalvin EC-1118 or going with a “real” cider yeast like the classical Mangrove Jacks M02 or the Fermentis Safcider yeast strain.

These cider yeasts produce a good amount of aromatic esters that add to the complexity and fruity notes of your cider.

I’ve used both extensively and had really great results with both. I prefer the M02 for sweeter ciders and the Safcider yeast for the more dry, champagne-like, ones.

Both will give your cider plenty of carbonation and alcohol content, but the wild yeast option will also add some funky flavors that can complement the sweetness of the apples nicely.

5. Wild Yeasts – Finally, if you’re feeling adventurous and want to experiment with fermentation beyond the standard winebeercider yeasts mentioned above, consider playing around with some wild yeasts !

These naturally occurring microbes can be found just about anywhere (including on fruits and in flower blossoms), so all you need is an open mind and willingness to let nature take its course.

Some popular strains include Saccharomyces cerevisiae var.diaemath, Brettanomyces bruxellensis ,and Rhodotorula rubra , but there are literally hundreds more out there waiting to be discovered…Happy fermenting!

Main Takeaway: Different types of yeast produce different types of alcohol.

What Cider Yeast Is Best For You?

As a home brewer, you have many options when it comes to choosing yeast for your cider. The type of yeast you choose will impact the flavor, mouthfeel, and overall quality of your cider.

Here are some things to consider when choosing yeast for your next batch:

1. What style of cider are you making?

Different styles of cider require different types of yeasts. For example, if you’re making a dry apple cider, then you’ll want to use a neutral-flavored or low-phenol strain of yeast.

However, if you’re making an English-style sweet or fruit forward ciders, then using traditional English strains with higher phenols will be more appropriate.

2. Consider What Flavors and Aromas You Want in Your Finished Product – This Can Help Guide Which Type of Yeast Is Best Suited for Your Needs.

For instance, if you want a crisp and dry cider with no secondary fermentation aromas like banana or clove, then using a white labs strain like the WLP775 Czech Pilsner will get you that result.

On the other hand, if you are looking for a full bodied and fruity cider then something like Red Star Premier Cuvee would work well.

There are many other factors that can impact the final flavor of your cider so always do experimentation to test what works best for you!

3. How much time do you have?

Some strains of yeast work faster than others – meaning that they ferment out completely in less time (usually around 2 weeks). Other strains may take longer (3-4 weeks) but can produce better results in terms of flavor development and complexity.

In general, most commercial brewers favor faster working yeasts as it’s easier to predict their behavior and manage fermentation times.

However, if you have patience and don’t mind waiting a bit longer for the finished product, then slower working yeasts may be a preference for this case.

4. What is your budget?

There are many different brands and strains of yeast available on the market, and they can vary widely in price.

Some home brewers prefer to use more expensive liquid cultures, while others are perfectly happy using dry yeasts that cost a fraction of the price.

It really comes down to personal preference – so find what works best for you and your budget.

5. Do you have any special needs or considerations?

Be sure to consider any dietary restrictions or allergies when choosing a yeast strain. Choosing the right type of yeast is an important part of making great cider at home.

Similarly, if you’re making cider for someone who is lactose intolerant, then using a lacto-fermenting yeast strain may not be appropriate.

By considering the style of cider you want to make, desired flavors and aromas, fermentation time, and budget, you can find the perfect yeast for your next batch!

Main Takeaway: The type of yeast you use will impact the flavor, mouthfeel, and overall quality of your cider. The outcome is a complex interplay, but the yeast, along with the types of cider apples, is probably the most important factor.

Best Cider Yeasts for Beginners

Cider brewing is a popular and rewarding hobby for many home brewers. The right yeast can make all the difference in your cider, so it’s important to choose wisely.

For beginners, there are several great options available that will help you get started on the path to making delicious hard ciders.

I would start out with one of the classical cider yeasts like the Mangrove Jacks M02 or the Fermentis Safcider yeast strain.

These cider yeasts produce a good amount of aromatic esters that add to the complexity and fruity notes of your cider.

But as you venture on, there are many factors to consider!

Temperature is another important factor when selecting a yeast strain for your cider recipe. Different strains have different temperature requirements so make sure to read up on what temperatures each strain prefers before pitching them into your fermenter. Generally speaking, ale and lager strains prefer cooler temperatures (around 65-68°F) while champagne and wine strains prefer warmer temperatures (around 70-75°F).

Flocculation ability is another important consideration when selecting a yeast strain for your cider recipe; some strains flocculate quickly while others take longer to settle out at the bottom of the fermenter after fermentation has completed.

Quickly flocculating yeasts tend to produce clearer ciders than those that take longer to settle out at the end of fermentation so if clarity is something you’re aiming for then opt for a quick flocculating strain like White Labs WLP001 California Ale Yeast or Safale US-05 Dry English Ale Yeast .

Finally, speed should be taken into account when selecting a yeast strain; some may finish their job faster than others depending on their attenuation rate which could be beneficial if time is limited but bear in mind that slower working strains usually yield better results due to increased complexity from extended contact times between sugar molecules and other components present during fermentation such as esters and phenols produced by certain types of bacteria or wild cultures added during primary fermentation stages..

Main Takeaway: The type of yeast used in cider brewing can have a big impact on the flavor and complexity of your finished product. Temperature and oxygen levels also play an important role in determining the speed of fermentation, with warmer temperatures accelerating it while lower oxygen levels slow it down. With proper sanitation practices, you can even reuse yeast multiple times for future batches.

English Cider Yeasts

English cider yeasts are a popular choice for home brewers. These yeasts produce a full-bodied, complex flavor that is often described as “traditional” or “old-fashioned”. They tend to be slow fermenters and can take up to two weeks to complete fermentation.

One of the most popular English cider yeast strains is WLP775 from White Labs. This strain produces an apple aroma with hints of citrus and pineapple, along with a dry finish that makes it ideal for traditional ciders.

It also has good flocculation ability, meaning it will settle out quickly after fermentation is complete so you don’t have to wait too long before bottling your cider.

Another popular English cider yeast strain is Wyeast 4766 Cider Yeast which produces an intense fruity character in the finished product while still allowing some sweetness to remain on the palate.

This strain ferments at lower temperatures than other varieties, making it well suited for cooler climates where temperatures may not reach into the high 70s Fahrenheit (25 Celsius). It also has excellent flocculation properties and tends to clear quickly once fermentation is complete.

Finally, there’s Safale S-04 Dry Ale Yeast which offers great results when used in hard ciders due to its neutral flavor profile and quick attenuation rate (the speed at which sugars are converted into alcohol). It ferments cleanly without producing any off flavors or aromas and clears nicely after fermentation has completed giving you a crisp tasting beverage every time!

Overall, these three strains offer something for all levels of homebrewers. Beginners who want an easy drinking yet flavorful beer can find what they need here, as well as advanced brewers looking for more complexity in their brews. When crafting your next batch of hard apple cider, consider one of these English cider yeasts.

English cider yeasts are the best choice for making hard ciders with a complex flavor and aroma. Next, let’s look at how to select and store yeast when making cider.

Main Takeaway: English cider yeasts are a popular choice for home brewers, offering a range of flavors and fermentation speeds. WLP775 from White Labs produces an apple aroma with hints of citrus and pineapple, while Wyeast 4766 Cider Yeast offers intense fruity character. Safale S-04 Dry Ale Yeast is also great for hard ciders due to its neutral flavor profile and quick attenuation rate. No matter your skill level, these three strains can help you craft the perfect hard apple cider!

Cider Yeasts for Advanced Brewers

Cider yeasts are a key component of the cider-making process, and advanced brewers should take the time to understand their different characteristics.

Different types of yeast can affect the taste, look, alcohol percentage and speed of fermentation in your cider. Understanding which type of yeast is best for your desired outcome will help you make better ciders with more consistent results.

English Cider Yeasts: English cider yeasts are considered traditional because they have been used for centuries in Europe to make dry ciders. These yeasts tend to produce less foam during fermentation and provide a crisp flavor profile that many people prefer in their ciders.

They also flocculate quickly, meaning they settle out at the bottom of your fermenter relatively soon after fermentation has finished. This makes them ideal for making clear ciders with low levels of sedimentation or haze when compared to other types of yeast strains available on the market today.

Can Cider Yeast be Reused?

Yes! You can reuse cider yeast multiple times if it is stored properly between batches; however, each successive batch may not be as good as the first one due to changes in temperature or oxygen exposure over time that can affect its performance and flavor profile.

It’s important to keep track of how many times you’ve reused a particular strain so you know when it’s time to replace it with fresh culture from a reliable source like White Labs or Wyeast Laboratories Incorporated (WL).

Additionally some specialty strains like Brettanomyces bruxellensis will produce unique flavors but require more patience since these wild cultures often take weeks or even months before reaching full attenuation levels required for optimal results when making beer or hard cider alike!

Tips To Increase The Speed Of Fermentation

If you want your hard apple juice fermented quicker then try raising temperatures slightly above room temperature (around 75F) while keeping an eye on airlock activity throughout this period – too much heat could cause off-flavors so monitor closely!

Also adding extra nutrients such as DAP (diammonium phosphate) helps promote healthy growth among cells leading up towards peak efficiency during active fermentation stages too – just remember not use too much otherwise there might be an undesirable sulfury smell coming from your brew later down line…

Contrary to speeding up the fermentation process, if slower fermentations are desired then lowering temperatures below 65F should do the trick.

This way, sugar conversion rate slows down significantly giving brewers enough time to adjust gravity readings before bottling or kegging without having to worry about potential bottle bombs.

Cider yeasts for advanced brewers offer a range of flavors and complexities that can be tailored to your taste. With the right knowledge, you can create an amazing cider with these yeasts.

Main Takeaway:

Temperature, oxygen availability and pH level all affect fermentation speed; raising temperatures slightly above room temperature will increase speed, while lowering temperatures below 65F will slow it down. Adding extra nutrients such as DAP can also promote healthy yeast growth for optimal results.

Can I Use Beer Yeast for Cider?

Yes! You can use beer yeast for making hard ciders; however, you should keep in mind that this will likely result in a slightly different flavor profile compared to what you would get using a traditional cider yeast strain.

This could mean either good or bad results depending on your preferences – so make sure you experiment small before committing too much time or money into a larger batch!

Different strains of yeast will produce different flavor profiles, so the exact flavors that you will get will depend on the specific strain of beer yeast that you use. In general, beer yeast will add more complex and nuanced flavors to your cider than cider yeast, which is often more neutral.

You may aim to get some fruity, spicy, or estery IPA-like flavors, depending on the type of beer yeast that you use. It’s best to experiment with different strains of yeast and see which flavors you like best.

What Are the Differences Between Beer Yeast and Cider Yeast?

Beer yeasts typically produce higher levels of esters than cider yeasts, which can give beer a more complex flavor profile. Additionally, beer yeasts tend to have faster fermentation times than cider yeasts due to their ability to flocculate quickly at warmer temperatures (around 68-72°F).

On the other hand, cider yeasts generally produce less esters than beer yeasts while still providing plenty of complexity in terms of flavor profiles; they also take longer to ferment as they prefer cooler temperatures (60-65°F) and do not flocculate as quickly as their counterparts.

The Pros & Cons Of Using Beer Yeast For Cider

Using beer yeast for making hard ciders has both advantages and disadvantages when compared with traditional cider strains:

Pros: Sometimes faster fermentation times due to its ability to ferment quickly at warmer temperatures; more complex flavors due to different levels of esters produced by these strains; easier availability since most homebrew stores carry multiple varieties of ale/lager/wheat beers which contain suitable brewing strains already included within them.

Ability to customize the flavor and aroma of beer, as well as its alcohol content; potential for cost savings compared to purchasing commercially-made beer.

Cons: Potentially off-flavors if not managed properly during fermentation process; potential incompatibility pH or temperatures range used for cider; more flat taste profile that does not support the properties of apples well.

Beer yeast can be used to make cider; however, it is important to consider the type of beer yeast and the brew you want and how the brewing conditions will affect the flavor profile of your cider.

Main Takeaway: Using beer yeast for making hard ciders can be a great way to customize the flavor and aroma of your cider, as well as its alcohol content. However, it is important to keep in mind that this will likely result in a slightly different flavor profile compared to what you would get using a traditional cider yeast strain.

Can I Use Baking Yeast for Hard Cider?

Baking yeast is a common ingredient in many recipes, but it’s not the best choice for hard cider.

Baking yeast is designed to quickly ferment sugars into carbon dioxide and alcohol, making it ideal for breads and other baked goods.

However, baking yeast doesn’t produce the same flavor profile as traditional cider yeasts. It also won’t create the desired level of alcohol content or carbonation that you would get from using a specialized cider yeast strain.

It will give a flat and neutral taste, and result in a somewhat cloudy cider as floculation is bad.

Can Cider Yeast Be Reused?

Cider yeast can be reused, but it’s important to understand the process and potential risks involved. Reusing yeast can save time and money, but there are a few things you should consider before attempting this method of fermentation.

Factors That Affect the Reusability of Yeast

When reusing yeast for cider making, several factors must be taken into account. These include how much alcohol was produced in the first batch, how long ago it was used, and whether or not any contamination occurred during storage.

If too much alcohol was produced in the first batch, then it may have killed off some of the viable cells needed for successful fermentation.

Additionally, if too much time has passed since its last use then most of those cells will have died off as well. Finally, if any contaminants were introduced during storage then they could cause problems with your second batch of cider as well.

Preparing Yeast For Reuse

If you decide to reuse your yeast after assessing all these factors then there are a few steps that need to be taken prior to pitching them into your next batch of cider.

First off you’ll want to make sure that all traces of sugar from the previous ferment have been removed by rinsing out your container thoroughly with water or sanitizer solution such as Star San or Iodophor (which is preferred).

Then add some fresh wort (unfermented beer) back into your container along with some nutrient-rich ingredients like DAP (diammonium phosphate) which will help feed and revive dormant cells so they can begin reproducing again once pitched into new wort/cider mixture.

Finally give everything a good stir before transferring it over to another clean container where you can store until ready for use again later on down the road when needed!

Risks Involved With Reusing Yeast

Reusing yeast does come with certain risks associated with contamination due to improper sanitation practices or using old batches that may no longer contain enough viable cells necessary for successful fermentation processes. This can result in poor tasting ciders at best, and contaminated ones at worst.

To avoid this, it is important to practice proper sanitation techniques throughout every step including cleaning and sanitizing containers regularly between uses.

Additionally, leftover yeasts should be stored properly either refrigerated or frozen depending on their age and activity levels so they do not spoil prematurely before being able to pitch them back into future batches successfully without issue.

Reusing cider yeast can be a great way to save money and time when making hard cider, but it’s important to understand the process before attempting it. The next heading will discuss the best practices for reusing cider yeast.

Main Takeaway: Reusing yeast for cider making can save time and money, but it is important to practice proper sanitation techniques and store leftover yeasts properly in order to avoid contamination. Factors such as how much alcohol was produced in the first batch, how long ago it was used, and whether or not any contaminants were introduced during storage should also be taken into account when deciding if reusing yeast is a viable option.

Temperature Control for Optimal Fermentation Results

Temperature control is an essential part of cider making, as it can affect the flavor, alcohol content and carbonation levels. Different yeasts have different temperature ranges in which they work best.

For example, ale yeast works best at temperatures between 60-70°F (15-21°C), while lager yeast works best at temperatures between 45-55°F (7-13°C). It’s important to maintain consistent temperatures during fermentation to ensure that the yeast performs optimally and produces a good quality cider.

Maintaining consistent temperatures during fermentation can be challenging for home brewers due to limited space or equipment. One way to do this is by using a refrigerator or freezer with a temperature controller set up inside it.

This allows you to adjust the temperature within your desired range without having to constantly monitor it manually. Another option is using an insulated box filled with water bottles that are frozen overnight and then placed around the fermenter when needed.

Cooling methods such as ice baths or cold water pumps may also be used if you don’t have access to refrigeration equipment.

Ice baths involve placing your fermenter into a large container filled with ice and water, while cold water pumps circulate chilled liquid through coils wrapped around your fermenter in order to cool it down quickly when necessary.

Both methods require some trial and error before finding what works best for you but can help keep your fermentation process on track if done correctly.

No matter which method you choose, monitoring the temperature regularly throughout fermentation will help to ensure that everything progresses smoothly and produces high quality results each time.

Temperature control is a key factor for successful cider making, and proper cooling techniques can help ensure the best fermentation results.

Flocculation Ability of Different Yeasts in Cider Making

Flocculation is an important process in cider making that affects the clarity and flavor of the final product.

Yeast flocculation refers to the ability of yeast cells to clump together and form a sediment at the bottom of fermentation vessels, which can be harvested for re-use or discarded.

Different yeasts have different levels of flocculation, so it’s important for home brewers to understand how this process works when selecting a yeast strain for their cider.

The definition of flocculation is relatively simple: it’s the aggregation or clumping together of particles suspended in liquid. In terms of brewing, this means that as fermentation progresses, some yeast cells will start to stick together and sink towards the bottom of your fermenter.

This creates a layer known as trub (short for “trubulent”) which can be removed from your beer or cider before bottling or kegging. The remaining clear liquid is then ready to drink!

When choosing a yeast strain for cider making, one factor you should consider is its level of flocculation – also referred to as attenuation rate – which indicates how well it will settle out during fermentation.

Highly-flocculent strains tend to produce clearer ciders with less sediment than low-flocculent strains; however, they may also take longer to complete fermentation due to their slower settling rates.

Low-flocculent strains are usually quicker but may leave more sediment behind after fermentation has finished – leading to an unclear cider.

There are several factors that affect a yeast’s ability to flocculate properly during cider making processes such as temperature control and aeration levels prior pitching; however there are also strategies available that can help improve results regardless if you choose high or low-flocculence yeasts such as adding fining agents like gelatin or polyclar prior bottling/kegging time frame.

Also make sure not overpitch too much yeast into your wort since overcrowding could lead into stuck ferments due lack oxygen availability among other things leading into poor quality beers/ciders overall with off flavors being present on them even though good gravity readings were achieved by end result..

Having a thorough understanding of how each type and strain of cider behaves under certain conditions, as well as adhering to proper sanitation practices, will greatly increase the chances of achieving desired results every time when homebrewing ciders.

The flocculation ability of different yeasts is a key factor in cider making and understanding the factors that affect it can help home brewers optimize their process for better results. Next, we’ll explore strategies to improve flocculation results in home brewing settings.

Main Takeaway: When making cider, it is important to consider the flocculation rate of the yeast strain being used. Highly-flocculent strains will produce clearer ciders with less sediment, but may take longer to ferment; low-flocculent strains are usually quicker but may leave more sediment behind. Temperature control and aeration levels prior pitching can help improve results, as well as adding fining agents like gelatin or polyclar before bottling/kegging.

Speed of Fermentation with Different Yeasts

When it comes to cider making, the speed of fermentation is an important factor that affects the taste and alcohol content of your final product. Different yeasts will have different effects on the speed of fermentation, so it’s important to understand how each type works in order to get the best results.

Factors That Affect The Speed Of Fermentation

The main factors that affect the speed of fermentation are temperature, yeast strain, and sugar concentration. Temperature plays a major role in determining how quickly your cider ferments; warmer temperatures can cause faster fermentations while cooler temperatures slow down or even stop them completely. Yeast strains also play a part as some types are more active than others at certain temperatures. Finally, higher sugar concentrations lead to faster fermentations since there is more food for the yeast cells to consume.

Tips To Increase The Speed Of Fermentation

If you want your cider to ferment faster then there are several things you can do: firstly raise the temperature slightly (around 20-25°C/68-77°F).

Secondly use a fast acting yeast such as Nottingham Ale Yeast or Safale US-05 which both work well at higher temperatures and have high flocculation abilities meaning they settle out quicker leaving clearer ciders behind them.

Finally add extra sugars such as honey or glucose syrup which will provide more food for your yeast cells leading to increased activity and therefore quicker fermentations times overall.

Strategies To Slow Down The Fermentation Process

If you are looking for slower fermentations, lower temperatures around 10-15°C/50-59°F should be used with slower acting yeasts such as White Labs WLP720 Sweet Mead Yeast or Lalvin 71B-1122 Wine Yeast.

These yeasts work better at cooler temperatures and will usually produce better, more aromatic, quality ciders when done correctly.

Read more about what cold does to cider fermentation here.

Additionally, adding fining agents such as bentonite clay can help clear up cloudy ciders by removing suspended particles from solution, thus slowing down fermentation rates due to their absorption properties and allowing time for further clarification before bottling occurs.

By understanding the factors that affect the speed of fermentation, implementing tips to increase it, and employing strategies to slow down the process, home brewers can have more control over their cider making process. Next we will look at how different types of yeasts affect fermentation in cider making.

Main Takeaway: The speed of fermentation is an important factor in cider making, and can be controlled by manipulating temperature, yeast strain, sugar concentration and fining agents. Using fast-acting yeasts at higher temperatures with added sugars will increase the rate of fermentation while slower acting yeasts at lower temperatures along with fining agents can slow it down. Understanding these factors will help you get the best results from your cider brewing process.

Cider Yeast FAQs

Does Cider Contain Yeast?

While store-bought cider is typically filtered to remove the yeast, there are some craft ciders that are made in small batches and contain yeast.

This yeast can give the cider a slightly different taste and can also cause the cider to be slightly less stable.

So, if you’re wondering whether store-bought cider contains yeast, the answer is that it typically does not. However, there are some craft ciders that are made in small batches and do contain yeast.

Is yeast always used in cider making?

Yes, yeast is used in making cider. Yeast plays an important role in the fermentation process of hard cider. It converts sugars from the apple juice into alcohol and carbon dioxide gas, giving it its characteristic fizziness and alcoholic content.

Different types of yeast can be used to produce different flavors and aromas in the final product. The choice of yeast also affects how quickly or slowly fermentation takes place, so it’s important to select a suitable strain for your desired outcome.

Does cider need yeast to ferment?

Yes, cider needs yeast to ferment. Yeast is essential for the fermentation process as it converts sugars in the juice into alcohol and carbon dioxide. Without yeast, there would be no fermentation and therefore no hard cider.

Different types of yeasts can be used to produce different flavors and aromas in the final product.

Experienced home brewers may choose a specific type of yeast based on their desired flavor profile or they may opt for a pre-made cider kit that contains all necessary ingredients including the appropriate strain of yeast.

Do you need to add yeast to make cider?

No, you do not always need to add yeast as wild yeast may be present on the apples used to make the apple juice.

If you use unpasteurised apple juice, there will likely already be wild yeast present in the juice and it will ferment into hard cider if left out at room temperature!

Can you put yeast in apple juice?

Yes, you can put yeast in apple cider to make hard cider. Yeast is a key ingredient for fermentation and will convert the sugars in the apple cider into alcohol.

It’s important to use a type of yeast specifically designed for making hard cider, as other types may not produce the desired results.

Additionally, it’s essential to follow instructions carefully when adding yeast so that your final product has just the right flavor and strength.

How much yeast do you put in homemade cider?

The amount of yeast you put in homemade cider depends on the specific recipe you are following. However, a good rule of thumb is to use 1/4 teaspoon of active dry yeast per gallon (4 liters) of cider.

This will give your cider a nice, crisp flavor and moderate alcohol content. If you want a sweeter cider with more body, then use 1/2 teaspoon per gallon.

And for a drier, higher-alcohol cider, use 1 whole teaspoon per gallon.

Be sure to add the yeast when the must (cider before fermentation) is at room temperature; adding it too early or too late can adversely affect fermentation and result in off flavors in your final product.

Can You Use Different Yeasts Together for Cider?

Different types of yeast can be used together in cider making, depending on the desired final product. However, care must be taken when using more than one type of yeast, as they can interact with each other and produce unexpected flavors.

It is generally best to use only one type of yeast, or to use a blend of yeasts that are known to work well together.

If you do decide to use multiple types of yeast, be sure to monitor the cider closely to ensure that it is fermenting properly and to taste it often to see how the flavors are developing.

Conclusion

In conclusion, yeast plays an important role in cider making. Different types of yeasts can be used to create different flavors and alcohol levels in your cider. Choosing the right yeast for your recipe is essential to get the desired results.

When choosing a yeast for your cider, it is important to consider all of these factors in order to find the best possible option for you.

There are many different strains of yeasts available on the market today, so be sure to do some research before making your final decision.

Commercial Yeast Reference table

I have collected some information about the most popular commercial yeasts here:

| Yeast Name | Primary Use | Approximate Alcohol Tolerance | Taste Characteristics | Optimal Temperature |

| Safale S-04 | Ale | 12% | Clean, Fruity, neutral flavor | 59-75°F (15-24°C) |

| White Labs WLP001 | Ale, Cider | 12% | Fruity, slightly spicy | 60-72°F (16-22°C) |

| Wyeast 1056 | Ale, Mead | 12% | Balanced, slightly fruity | 60-72°F (16-22°C) |

| Saflager S-23 | Lager | 13% | Clean, crisp, slightly malty | 46-59°F (8-15°C) |

| White Labs WLP830 | Lager | 13% | Clean, crisp, slightly malty | 46-59°F (8-15°C) |

| Wyeast 2007 | Lager | 13% | Crisp, slightly spicy, malty | 46-59°F (8-15°C) |

| White Labs WLP300 | Hefeweizen | 12% | Banana, clove, spicy | 64-75°F (18-24°C) |

| Wyeast 3638 | Hefeweizen, Belgian | 12% | Banana, clove, spicy | 65-75°F (18-24°C) |

| White Labs WLP500 | Belgian | 13% | Fruity, spicy, complex | 65-75°F (18-24°C) |

| Wyeast 1214 | Belgian | 13% | Fruity, spicy, complex | 65-75°F (18-24°C) |

| Danstar Nottingham | Dry | 11% | Neutral, slightly malty | 60-72°F (16-22°C) |

| Fermentis Safale US-05 | Dry | 12% | Neutral, slightly fruity | 59-75°F (15-24°C) |

| Lallemand BRY-97 American West Coast Ale Yeast | Dry, Champagne | 13% | Neutral, slightly fruity | 60-72°F (16-22°C) |

| White Labs WLP380 | Wheat beer | 12% | Banana, clove, spicy | 64-75°F (18-24°C) |

| Wyeast 3333 | Wheat beer | 12% | Banana, clove, spicy | 64-75°F (18-24°C) |

| White Labs WLP565 | Saison | 13% | Fruity, spicy, complex | 65-75°F (18-24°C) |

| Wyeast 3711 | Saison | 13% | Fruity, peppery, spicy, complex | 65-75°F (18-24°C) |

| White Labs WLP644 | Fruit beer, Mead | 12% | Fruity, spicy, complex | 65-75°F (18-24°C) |

| Wyeast 5112 | Fruit beer | 12% | Fruity, spicy, complex | 64-75°F (18-24°C) |

| White Labs WLP002 | Ale | 12% | Fruity, slightly spicy | 60-72°F (16-22°C) |

| Wyeast 1318 | Ale | 12% | Fruity, slightly spicy | 60-72°F (16-22°C) |

| White Labs WLP775 | Cider | 14% | Fruity, slightly spicy | 59-75°F (15-24°C) |

| Wyeast 4766 | Cider | 14% | Fruity, slightly spicy | 59-75°F (15-24°C) |

| Fermentis Safale S-04 | Beer | 16% | Neutral, slightly fruity | 59-75°F (15-24°C) |

| Lallemand BRY-97 American West Coast Ale Yeast | Champagne, Dry | 13% | Neutral, slightly fruity | 60-72°F (16-22°C) |

| Fermentis Safwhite | White wine | 13% | Neutral, slightly fruity | 59-75°F (15-24°C) |

| Lallemand Eau de Vie Yeast | White wine | 16% | Fruity, floral, spicy | 64-75°F (18-24°C) |

| Fermentis Safale S-33 | Red wine | 12% | Neutral, slightly fruity | 59-75°F (15-24°C) |

| Lallemand Bourgovin RC212 | Red wine | 16% | Fruity, spicy, complex | 18-30°C (64-86°F) |

| Lavin D254 | Wine | 16% | Fruity, floral, spicy | 12-28°C (53-82°F) |

| Lallemand RC212 | White wine, Red wine | 16% | Fruity, spicy, complex | 18-30°C (64-86°F) |

| White Labs WLP720 | Mead | 15% | Slightly fruity and sweet | 70-75°F (21-24°C) |

| Wyeast 4134 | Sake | 14% | Full bodied profile, silky and smooth | 60-75°F (16-24°C) |

| White Labs WLP650 | Mead | 13-16% | Fruity, spicy, and funky with a balanced acidity | 65-75°F (18-24°C) |

| Wyeast 5151 | Mead | 9-12% | Estery and spicy with a complex fruitiness | 65-75°F (18-24°C) |

-recipe.jpg)