Introduction

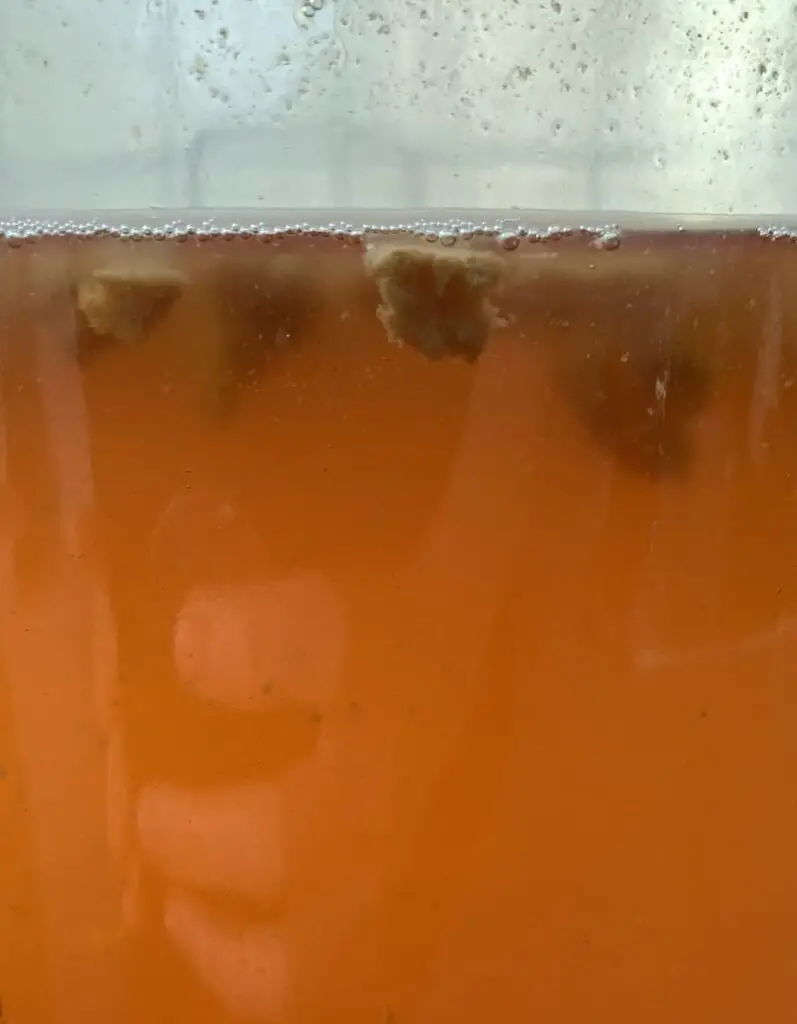

Cold crashing is the process of rapidly lowering the temperature of your brewed beer or cider before bottling or kegging. This process helps clarify the beer, remove unwanted flavors, and improve the overall taste by allowing solids like yeast and hop particles to settle at the bottom.

But what if you don’t have a fridge or a dedicated brewing refrigerator? Can you still cold crash? Absolutely!

This article will explore alternative methods to cold crash your beer even without a fridge.

Quick Summary

- Cold crashing helps in clarifying beer and enhancing its taste.

- It typically requires lowering beer temperature quickly.

- While fridges are commonly used, there are effective alternative methods.

- We’ll explore methods such as ice baths, evaporative cooling, using underground cellars, and more.

The Importance of Cold Crashing

Cold crashing beer brings forth multiple benefits. The most significant of these is clarity. Cold crashing allows particulates to settle, rendering a clearer beer.

This not only improves the beer’s appearance but also its flavor. Residual yeast and other particles can contribute off-flavors.

By allowing them to settle, you’re left with a beer that tastes clean and true to its intended profile.

Basic Principles of Alternative Cooling

The art of cooling without a refrigerator revolves around the principles of heat transfer and insulation. When trying to cold crash beer, you’re essentially trying to transfer the heat from the beer to its surroundings. The rate of this transfer can be influenced by external conditions, such as ambient temperature. The more difference between the beer’s temperature and the surrounding environment, the faster the cooling.

Cold Crashing Methods Without a Fridge

Ice Bath

Using an ice bath is one of the most direct methods to cold crash indoors and year round.

- Procedure: Secure your fermenter and place it in a large tub or container. Fill the container with water until the fermenter is mostly submerged, then add ice.

- Duration: Keep the beer in the ice bath for 24-48 hours, occasionally adding ice to maintain the cold.

- Pros: Rapid cooling, easily accessible.

- Cons: Requires frequent monitoring and ice replenishment.

Evaporative Cooling

Nature’s own cooling mechanism!

- Procedure: Wet a cloth or towel and wrap it around your fermenter. Place the fermenter in a breezy or windy area.

- Science: As water evaporates from the cloth, it takes heat from the beer with it, causing cooling.

- Pros: Simple, no direct costs.

- Cons: Less effective in high humidity or non-breezy areas.

Using Underground Cellars or Basements

Taking advantage of the Earth’s consistent temperatures.

- Procedure: Store the beer in the deepest part of your cellar or basement where temperatures remain consistently cool.

- Pros: Stable temperatures, no direct intervention needed once placed.

- Cons: Not all homes have basements or cellars.

Cool Water or Snow

Harnessing the power of Mother Nature, cool water and snow can be one of the most effective ways to cold crash beer without the use of mechanical equipment.

- Procedure for Cool Water:

- Find a location where the water is naturally cold, such as a spring, well, or shaded pond.

- Submerge your sealed beer fermenter in the water, ensuring it’s anchored or weighted down so it doesn’t float or get carried away by currents.

- Monitor the temperature regularly and ensure that the beer stays submerged for optimal cooling.

- Procedure for Snow:

- If you’re in a snowy environment, this is an excellent opportunity to cold crash naturally.

- Dig a hole in the snow and place your fermenter inside, ensuring it’s surrounded by snow on all sides.

- Pack the snow around the fermenter tightly for maximum cooling. The snow not only cools the fermenter but also acts as an insulator, maintaining the cold temperatures for a more extended period.

- Science Behind It:

- Both water and snow have a high heat capacity, which means they can absorb a significant amount of heat before their own temperature starts to rise. This makes them excellent mediums for pulling heat away from the beer, allowing it to cool down efficiently.

- Pros:

- Using natural elements, so no need for electrical equipment or additional costs.

- Snow, in particular, provides prolonged insulation, ensuring a consistent temperature over time.

- Cons:

- Dependent on natural conditions. Not everyone will have access to cold natural water or snow.

- Risk of contamination if the fermenter isn’t sealed properly.

- In the case of snow, if it’s a sunny day, the sun can melt the snow around your fermenter, so it’s crucial to monitor the setup regularly and replenish the snow if necessary.

Utilizing cool water or snow is not just effective but also environmentally friendly, as it relies on natural resources. It’s a testament to the fact that sometimes, the best solutions are the ones nature provides.

Tips to Enhance Efficiency of Cold Crashing

Insulation

Insulating your fermenter can help maintain desired temperatures.

- Use materials like blankets, Styrofoam, or specially designed wraps.

Rotation

Rotating the beer helps in achieving even cooling.

- Ensures consistent temperatures throughout the beer.

Monitor Temperatures

Keep track of the beer’s temperature.

- Use thermometers or temperature strips.

- Helps in maintaining the desired temperature range.

Safety Precautions

- Always ensure that the beer fermenter is sealed properly to prevent any contamination.

- When using natural bodies of water, ensure the beer doesn’t get submerged or swept away.

Potential Challenges and Solutions

Ice Bath

Challenge: Melting ice can dilute the water, which may affect its temperature maintaining capacity.

Solution: Use sealed ice packs or plastic bottles filled with frozen water. This way, as the ice melts, it doesn’t dilute the bath.

Evaporative Cooling

Challenge: This method’s efficiency can plummet in areas of high humidity.

Solution: Pair this method with a fan or another source of constant airflow to maximize evaporation, even in more humid conditions.

Underground Cellars or Basements

Challenge: Cellars and basements might have other odors or contaminants.

Solution: Ensure your fermenter is sealed. Store beer in a secondary container or off the ground to avoid any potential contaminants.

Cool Streams or Bodies of Water

Challenge: Rapid water currents can potentially displace or damage your fermenter.

Solution: Secure your fermenter with weights or tie it to a stationary object like a tree or a stake driven into the ground.

Potential Additives for Enhanced Cold Crashing

While the focus is on physical methods to cold crash, certain additives can assist in the process:

Gelatin

Gelatin is a clarifying agent that, when added before cold crashing, helps in pulling down yeast and other particles, speeding up the clarification process.

Isinglass

Derived from fish bladders, this is another fining agent that can help in pulling down particles, making your beer clearer, faster.

Consider Using a Conical Fermenter

Conical fermenters have risen in popularity among homebrewers and professionals alike, and there are strong reasons why. When discussing cold crashing, especially without a fridge, the conical fermenter offers unique advantages.

What is a Conical Fermenter?

A conical fermenter is a vessel designed primarily for the fermentation and conditioning of beer. Its shape – similar to an inverted cone – differentiates it from traditional cylindrical fermenters. This design has practical implications for the brewing process.

Benefits of a Conical Fermenter in Cold Crashing:

1. Efficient Sediment Collection: Due to its conical shape, as the beer cools and particles settle during the cold crashing process, they accumulate at the bottom of the cone. This means clearer beer can be drawn from the top while leaving the sediment behind.

2. Easy Trub Removal: Many conical fermenters come with a valve at the bottom. Once your beer has cold crashed and the sediment is settled at the bottom, you can easily remove this trub without disturbing the clear beer above.

3. Reduces Beer Loss: Traditional methods might require transferring beer from one vessel to another to leave the sediment behind. With a conical fermenter, there’s no need for this transfer, reducing the risk of beer loss.

4. Adaptability: Some conical fermenters are designed to be pressurized. This means you can potentially carbonate directly in the fermenter after cold crashing, further reducing the need to transfer beer.

5. Improved Temperature Control: Many modern conical fermenters come equipped with jackets or coils that allow for liquid (like cold water or glycol) to circulate around them. This is an excellent feature for those trying to cold crash without a fridge, as you can use ice water or other cooling methods in conjunction with the fermenter to achieve desired temperatures.

FastFerment Conical Fermenter

When buying a conical fermenter, consider:

1. Cost: Conical fermenters are typically more expensive than their traditional counterparts. However, many brewers find that the benefits outweigh the initial investment, especially when considering the potential for reduced beer loss and improved quality.

2. Space: These fermenters, especially the larger ones, can take up more space. Ensure you have an appropriate location to store them, particularly if you’re considering underground or ice bath methods for cold crashing.

3. Maintenance: The added components, such as valves and sometimes electronics (for those with built-in temperature controls), mean there could be more maintenance involved compared to traditional buckets or carboys.

Conclusion:

For those serious about brewing and seeking more control over their cold crashing process, especially without a dedicated fridge, a conical fermenter is worth considering. Its design promotes clarity, reduces waste, and can integrate well with alternative cooling methods.

Personalizing the Process

Remember, every brew and brewer is different. What might work exceptionally well for one might not be the best for another. It’s essential to:

- Experiment: Don’t be afraid to try different methods or combine them. Maybe an ice bath combined with evaporative cooling works best for you.

- Document: Maintain a brewing journal. Note down what method you used, for how long, and the results. Over time, this will be invaluable in refining your process.

- Share and Learn: The brewing community is vast and always willing to help. Share your experiences, learn from others, and continuously evolve your methods.

Conclusion

Cold crashing is a valuable step in brewing, enhancing clarity and flavor. Even without a fridge, numerous methods can be employed, each with its own advantages and challenges. By understanding the principles, experimenting with different techniques, and learning from each batch, you can achieve fantastic results. So, raise a glass to ingenuity and cheers to great beer!

FAQs

1. Can I cold crash in outdoor winter conditions?

Absolutely! If you live in an area with cold winters, the outdoor environment can be an excellent natural refrigerator. However, ensure that your beer doesn’t freeze, as this can lead to undesirable flavors and can potentially harm the beer’s structure.

2. How will I know if I’ve cold crashed for too long?

Cold crashing is typically a safe procedure, but if done for extended periods (beyond a week, for example), you might risk stripping out more flavor and aroma than desired. If you notice your beer lacking the desired aroma or taste, consider reducing the cold crash duration next time.

3. Do I need to adjust the carbonation levels after cold crashing?

Cold crashing can lead to CO2 dissolution in the beer, meaning you might need to adjust carbonation levels slightly post-cold crash, especially if you’re bottle-conditioning. A forced carbonation system (like a kegging setup) can be more forgiving.

4. Will cold crashing affect the shelf life of my beer?

Actually, cold crashing can extend the beer’s shelf life. By removing excess particulates, yeast, and potential off-flavors, your beer will likely have a more extended period of optimal taste. However, always ensure you store beer in suitable conditions afterward.

5. Can I reuse the yeast that settles at the bottom after cold crashing?

Yes, the yeast that settles post-cold crash is viable and can be harvested for reuse in future batches. Ensure you store the collected yeast in sanitary conditions and use it within a reasonable timeframe to maintain its health and viability.