The Total Dissolved Solids (TDS) and Water Hardness is important to understand when brewing. TDS and water hardness can have a major impact on the brewing process, the outcome of the beverage, as well as the taste, yeast performance, and pH.

It is essential to understand and be able to measure these levels in order to achieve the desired results.

In order to help brewers achieve the desired results, this article will provide a detailed explanation of TDS and water hardness and their impact on brewing.

This article will also explain different testing methods, desired levels in brewing, how to measure TDS and water hardness, and various methods for purifying and conditioning water. Finally, this article will explain the different effects of TDS and water hardness on beer, cider, wine and mead brewing.

Impact of TDS and Water Hardness on Brewing

Water hardness is an important factor when it comes to brewing beer, cider, wine, and mead. The total dissolved solids (TDS) and water hardness have the potential to affect the taste, yeast performance, aging, and pH of the final product. Understanding the impact of TDS and water hardness on brewing is essential for creating the perfect beverage.

The effect of TDS and water hardness on taste is one of the most important considerations. TDS can have a negative effect on the flavor of beer due to off-flavors like sulfates and chlorides.

Hard water can also create harsh or metallic flavors, particularly in light-colored beer styles. On the other hand, soft water can lead to a lack of perceived bitterness, although brewers can still use hops to add bitterness.

The performance of the yeast is another crucial factor that is affected by TDS and water hardness. Hard water can inhibit the activity of the yeast, leading to slower fermentation and off-flavors in the final product. Soft water, on the other hand, can lead to over-fermentation and a lack of body in the beverage.

The aging of beer, cider, wine, and mead is also affected by the TDS and water hardness. Hardness can interact with proteins and polyphenols, which can lead to complications during aging. Soft water can also lead to a quicker aging process and can cause the flavors of the beverage to become muddled.

The pH of the beverage is also impacted by the TDS and water hardness. Hard water can lead to higher pH levels due to higher calcium and magnesium levels, which can create a smoother flavor. Soft water can lead to a lower pH, which can lead to sharper flavors and more aggressive bitterness.

It is important to understand the impact of TDS and water hardness on brewing in order to create the perfect beverage. Brewers need to be aware of how TDS and water hardness can affect the taste, yeast performance, aging, and pH of the final product in order to create the perfect beer, cider, wine, or mead.

Testing TDS/Hardness Levels

When it comes to brewing, monitoring the levels of Total Dissolved Solids (TDS) and water hardness is essential. Knowing the current TDS and water hardness levels of the water used in the brewing process will help brewers determine the expected outcome of their chosen beverage.

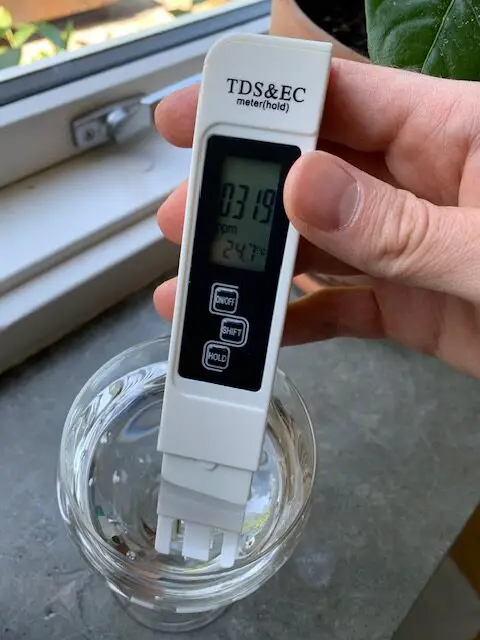

Testing TDS and water hardness levels requires specific tools and equipment. One of the most popular methods for testing TDS and water hardness is the use of a Total Dissolved Solids meter, also sometimes referred to as a Salinity Meter (although it measures more than ordinary salt!).

This tool measures the amount of salt in water and is used to determine the TDS level. A hardness test kit, or a Calcium Hardness test kit, can be used to measure water hardness.

TDS Meter Digital Water Tester

Other methods for testing TDS and water hardness include titration and direct reading instruments. Titration measures the amount of alkalinity or acidity in water, which can help brewers determine the TDS level of their water supply.

Direct reading instruments measure the amount of certain ions present in water, such as calcium, magnesium, and sodium.

When testing TDS and water hardness levels, it is important to consider the accuracy of the testing method. While a Total Dissolved Solids meter is fairly accurate, other testing methods may not be as precise. Additionally, it is important to consider the desired outcome of the brewing process, as the TDS and water hardness levels may need to be adjusted depending on the type of beverage being brewed.

Understanding the TDS and water hardness levels of the water used in the brewing process can help brewers ensure a successful outcome. With the right tools and equipment, brewers can accurately test the TDS and water hardness levels of their water supply, and adjust them as needed. This will help brewers achieve the desired taste, texture, and clarity of their chosen beverage.

TDS and Water Hardness Levels

Understanding the TDS and water hardness levels of your brewing water is essential for achieving the desired outcome of your beer, cider, wine, or mead.

The levels of TDS and water hardness can impact the taste, yeast performance, aging, and pH of your brew. Depending on the type of brew, desired levels of TDS and water hardness vary.

First, it is important to understand what TDS and water hardness are and how to measure them. TDS stands for Total Dissolved Solids, and it is a measure of the amount of minerals, salts, metals, and other substances that are dissolved in the water.

The more dissolved solids, the higher the TDS. Water hardness is a measure of the amount of calcium and magnesium salts, also called hardness ions, dissolved in the water. Hard water has a higher concentration of these salts and can be identified by its chalky taste.

When it comes to brewing, the ideal TDS value is between 150-300 ppm (parts per million). For water hardness, the desired level depends on the type of brew.

For beer brewing, a water hardness between 50-150 ppm is ideal, while for cider, the desired range is between 25-50 ppm. For wine brewing, the ideal hardness range is between 50-150 ppm, while for mead, it should be between 25-50 ppm.

Testing the TDS and water hardness levels of your brewing water is necessary to determine if it is suitable for your type of brew. There are different methods of testing, such as using test strips, a TDS meter, or a water hardness test kit. For accurate readings, you will need to use the right tools and equipment.

In addition to testing the TDS and water hardness levels of your brewing water, it is also important to pay attention to the saturation levels. Oversaturation can result in poor beer clarity, while under-saturation can cause poor hop utilization.

If your water is oversaturated, you can add distilled water to reduce the TDS and water hardness levels. If your water is under-saturated, you can add salts, such as gypsum or calcium chloride, to increase the TDS and water hardness levels.

It is important to understand the role of TDS and water hardness in brewing, as it can have a significant impact on the outcome of your beer, cider, wine, or mead. By testing and adjusting the TDS and water hardness levels of your brewing water, you can ensure that your brew will have the right flavor, yeast performance, aging, and pH.

Adjusting TDS/Hardness in Brewing

Adjusting the total dissolved solids (TDS) and water hardness levels in brewing is a crucial step for achieving the desired beer, cider, wine, or mead profile. It can be a complex and time-consuming process, but it is essential for producing a quality product.

The most common way to adjust TDS and water hardness levels in brewing is to use additives such as salts, bases, and acids.

The first step in adjusting TDS and water hardness levels in brewing is to identify the desired levels of TDS and water hardness. This will depend on the type of brew being produced.

For example, grain-based beers require softer water than those made with hop-based recipes. Once the desired levels have been established, the brewer can begin to adjust the TDS and water hardness levels using various additives.

The most common additive used to adjust TDS and water hardness levels in brewing is calcium chloride. This is a common brewing salt that will increase the calcium levels and reduce the carbonate levels in the brewing water.

Other common additives used to adjust TDS and water hardness levels are magnesium sulfate, sodium bicarbonate, and potassium chloride.

Each of these additives will affect the TDS and water hardness levels differently, so it is important to understand how each of these will affect the brewing process.

Another way to adjust TDS and water hardness levels in brewing is to use reverse osmosis (RO) filtration systems. This type of system will remove minerals from the water, reducing the TDS and water hardness levels. While this method may be effective for some brewers, it can be costly and time-consuming, and can also reduce the flavor complexity of the beer.

Finally, it is important to monitor the TDS and water hardness levels throughout the brewing process. This will ensure that the desired levels are being obtained and can help prevent any unwanted flavors from developing as a result of incorrect TDS and water hardness levels. Brewers can use a variety of test kits and meters to measure the TDS and water hardness levels in their brewing water.

Adjusting TDS and water hardness levels in brewing is a crucial step in producing a quality product. By understanding the desired levels and using the right additives and test kits, brewers can ensure that their beer, cider, wine, or mead is of the highest quality.

Purification

The process of purifying water in brewing is an essential step to ensure the best possible taste, aroma, and overall quality of your beer, cider, wine, or mead. Without proper purification, the water used in brewing can contain too many minerals, which can lead to off-flavors in your final product, as well as issues with the fermentation process.

Water purification involves removing certain elements, such as metals, calcium, magnesium, and other impurities, that can have an adverse effect on the brewing process and the flavor of the beer, cider, wine, or mead.

The most common method of purifying water is by chemical purification, which involves using a filtering system and chemical additives to remove the impurities.

Chemical purification works by adding a chemical such as sodium bicarbonate or calcium chloride to the water, which binds to the minerals and renders them insoluble. This makes it possible to filter out the minerals and other impurities, leaving behind pure, filtered water.

In addition to chemical purification, mechanical purification is another popular method of purifying water for brewing. Mechanical purification involves using a number of different processes, such as charcoal filtration, reverse osmosis, and distillation to remove impurities from the water.

Mophorn Pure Water Distiller

Charcoal filtration is one of the most common methods of mechanical purification and involves passing the water through a bed of activated carbon, which traps the impurities and removes them from the water. Reverse osmosis is another popular method and involves using a semi-permeable membrane to remove impurities from the water.

Finally, distillation involves boiling the water and collecting the steam that is produced, which contains pure water.

Distillation of water is probably the best and long term cheapest and safest way to purify your water for brewing.

Distillation also gets rid of other ions that inflence the taste of water suchs as chloride and flourinde, metal ions, pesticides and other chemicals.

No matter which method of purification you decide to use, it is important to ensure that the water you use for brewing is free of impurities and that the TDS and water hardness levels are suitable for the type of beer, cider, wine, or mead that you are brewing.

TDS and Water Hardness in Beer Brewing

The composition of the water used to brew beer has a significant impact on the taste and quality of the finished product. TDS and water hardness levels both play a role in the beer brewing process, from grain absorption rates to pH balance and hop utilization. An understanding of TDS and water hardness is essential in order to produce craft beer that is consistently top quality.

TDS stands for ‘Total Dissolved Solids’ and refers to the concentration of dissolved minerals in water. TDS can be measured using a digital TDS meter, and the ideal level for brewing beer is between 0-150ppm (parts per million). A TDS reading higher than 150ppm indicates that the water is hard, which can interfere with the grain absorption process and affect the flavor of the beer.

Water hardness is the measure of calcium and magnesium ions in the water. The higher the levels of these ions, the harder the water. Water hardness is usually measured in milligrams per liter (mg/L). Generally, the ideal water hardness level for brewing beer is between 0-50mg/L. If the water is too hard, it can cause an overly bitter taste in the beer, as well as affecting the pH balance and hop utilization.

The pH balance of the water also plays a role in beer brewing. The ideal pH level for brewing beer is between 6.0 and 7.5, as this is the range in which enzymes have the highest activity. If the pH balance is too high or too low, the enzymes will not be as active, which will affect the flavor and character of the beer.

When it comes to grain absorption rates, TDS and water hardness have a direct effect. If the TDS and water hardness levels are too high, the grains will absorb too much water and can cause astringency in the beer. If the levels are too low, the grains will absorb too little water and the beer will be lacking in flavor.

The level of water hardness and TDS also affects hop utilization. The higher the levels, the more bitter the beer will be, as the hops are unable to release their aromatic compounds due to hard water.

Finally, the levels of TDS and water hardness also affect the clarity of the beer. If the levels are too high, the beer will be cloudy and hazy, whereas if the levels are too low, the beer will be clear but will lack flavor and body.

In conclusion, it is important for brewers to understand the role of TDS and water hardness in beer brewing in order to produce consistently top-quality craft beer. By measuring the TDS and water hardness levels, brewers can adjust the levels if necessary in order to attain the desired flavor and character of the beer.

TDS and Water Hardness in Cider Brewing

Cider-making is a centuries-old art, but the science behind its success has only recently been understood. In cider brewing, the combination of Total Dissolved Solids (TDS) and water hardness in the ground where apples are grown can have a significant impact on the flavour, aroma and clarity of the finished product.

Also, and especially, if you use juice concentrate for cider brewing, and therefore need water to dilute it, the water used will impact the taste.

TDS are a measure of the total amount of mineral substances dissolved wether in water or in the juice. juice hardness is a measure of the amount of calcium and magnesium present in the juice, and can be expressed as either grains per gallon (GPG) or parts per million (PPM).

In cider brewing, both TDS and juice hardness can influence the fermentation process, the tartness of the cider, and the overall flavour.

The desired TDS and juice hardness levels for cider brewing can vary depending on the type of cider being brewed. Generally speaking, the higher the TDS and juice hardness, the slower the fermentation process and the higher the final gravity of the finished product.

This can result in a richer, sweeter cider, but can also lead to a cider with more complex flavours. Conversely, lower TDS and juice hardness can lead to a faster fermentation process and a drier cider.

The desired juice hardness levels for cider brewing also vary depending on the type of cider being produced.

For dry ciders, low juice hardness is desirable because it helps to produce a crisper, less sweet cider. On the other hand, higher juice hardness is desirable for sweet or semi-sweet ciders, as it can help to add body and complexity to the cider.

The levels of TDS and juice hardness can be measured using a number of different methods, such as titration, ion-selective electrodes and spectrophotometry. In general, it is best to use a combination of different testing methods to get a comprehensive overview of the juice before brewing.

When adjusting the levels of TDS and juice hardness in cider brewing, it is important to be careful not to oversaturate or undersaturate the juice. In general, the ideal TDS and juice hardness levels should be between 5 and 25 PPM. If the levels are too high, then the cider may become overly sweet, while too low a level could lead to a too-tart cider.

In order to purify and condition the juice before cider brewing, there are a number of different methods available. Chemical purification is often used to remove unwanted substances from the juice. This can include both chemical ions and bacteria, depending on the specific purification process. Mechanical purification, on the other hand, can be used to remove suspended solids, such as sand and dirt, from the juice.

In conclusion, understanding the science behind TDS and juice hardness in cider brewing is essential for producing a flavorful, balanced cider. By testing, adjusting and purifying the juice, cider brewers can ensure that their cider will have the perfect balance of sweetness, tartness and complexity.

TDS and Water Hardness in Wine Brewing

The quality and flavour of wine is heavily influenced by the type of grape juice used in the brewing process. grape juice hardness and TDS levels play an important role in producing the desired outcome of a wine. The levels of hardness and TDS in the grape juice will affect the fermentation process and the flavour profile of the wine.

TDS stands for total dissolved solids and it is an important measure of grape juice quality. TDS levels measure the amount of minerals and other particles that are present in the grape juice. A higher TDS level in the grape juice will lead to a higher concentration of minerals in the wine. This higher concentration of minerals can affect the taste of the wine, as well as its colour and clarity.

grape juice hardness is another measure of grape juice quality. Hardness is measured by the amount of calcium and magnesium present in the grape juice. Hard grape juice will contain higher levels of calcium and magnesium than soft grape juice. Hard grape juice is often used for producing full-bodied and fuller flavoured wines. Soft grape juice, on the other hand, is usually used for producing lighter flavoured wines.

Different types of wine require different levels of hardness and TDS in the grape juice. For example, dry white wines require a lower TDS level and softer grape juice than red wines. A higher TDS level and harder grape juice will give the wine a deeper colour and a fuller body.

The levels of TDS and grape juice hardness also have an effect on the fermentation process. High levels of TDS and grape juice hardness can make the yeast cells grow slower and produce less alcohol during fermentation. Low levels of TDS and grape juice hardness can result in a faster fermentation process but the end product can be less flavourful.

The pH balance of the grape juice is also affected by the levels of TDS and grape juice hardness. The pH level of the grape juice will influence the flavour and aroma of the wine. A higher pH level will cause the wine to be more acidic and can make the wine taste bitter. A lower pH level can make the wine taste flatter and lack in complexity.

The desired levels of TDS and grape juice hardness can be achieved by adding certain minerals or chemicals to the grape juice. This process is called grape juice conditioning and it is a common practice in winemaking. Different types of wine require different levels of TDS and grape juice hardness, so it is important to understand the desired levels for each type of wine before adding any minerals or chemicals to the grape juice.

TDS and grape juice hardness levels play an important role in the brewing process of wine. A winemaker must take into consideration the desired TDS and grape juice hardness levels for each type of wine, as well as the effect of the pH balance on the flavour and aroma. By understanding and adjusting the levels of TDS and grape juice hardness, a winemaker can achieve the desired outcome of a particular wine.

TDS and Water Hardness in Mead Brewing

Mead brewing involves a fermentation process that is affected by both TDS and water hardness levels.

Because you mix honey and water when brewing mead, the water quality will affect the final result.

TDS is a measure of the total amount of dissolved solids in the water and, when it comes to brewing mead, should generally be kept between 50 and 150 parts per million (ppm).

The pH balance of the water used in mead brewing is very important, as it helps to bring out the flavour and aroma of honey. Water with higher TDS and water hardness levels typically has higher alkalinity, which can cause the honey flavour and aroma to be muted, and even lead to off-flavours in the mead. On the other hand, water with lower TDS and water hardness levels can result in a thin or watery mead with little complexity and reduced honey flavour and aroma.

The TDS and water hardness levels also affect the yeast nutrient uptake, as the yeast will not be able to absorb the nutrients from the water if the pH balance is off. If the TDS and water hardness levels are too high, the yeast may struggle to complete the fermentation process, and it may take longer for the mead to reach its desired alcohol content.

Another important factor to consider is the effect of TDS and water hardness levels on mead clarity. Water with high levels of TDS and water hardness can result in a cloudy, hazy mead. This is because the higher TDS and water hardness levels can cause the proteins in the mead to denature and form large insoluble complexes, which give the mead a cloudy appearance.

Overall, it is important to understand the impact of TDS and water hardness levels on mead brewing. By understanding the desired TDS and water hardness levels and ensuring that the correct pH balance is maintained, brewers can ensure that their mead has the desired flavour, aroma, and clarity.

Other Considerations

When discussing TDS and water hardness in the brewing process, it is important to understand the difference between Total Dissolved Solids (TDS) and specific ions. TDS measure the total amount of all dissolved solids, including minerals, salts, and organic matter. The specific ions refer to the individual elements that make up TDS, such as calcium, magnesium, sodium, potassium, and chloride.

In addition to TDS and water hardness, alkalinity and acidity are two other parameters that impact the brewing process. Alkalinity is a measure of the buffering capacity of water, and is determined by the presence of carbonates, bicarbonates, and hydroxides.

It is essential to understand the alkalinity of the water when brewing. In beer brewing, it is important for the pH to remain stable, and the addition of minerals and acids to the water can help achieve this. For example, adding calcium carbonate to the water will increase the alkalinity, making it more difficult for the pH to drop.

Acidity is determined by the presence of carbon dioxide, sulfides, and phosphates. The acidity of the water can influence fermentation, as acids can inhibit the activity of the yeast. In beer brewing, the acidity of the water can also contribute to the flavor and aroma of the final product.

Another consideration when discussing TDS and water hardness in brewing is the amount of dissolved solids in the water. Dissolved solids are components such as minerals, salts, and organic matter that can affect the flavor and aroma of the final product. It is important to ensure that the correct amount of dissolved solids is present in the water, as too little or too much can have a negative effect on the beer.

All of these considerations must be taken into account when assessing the impact of TDS and water hardness on the brewing process. The correct levels of TDS and water hardness are essential for the successful production of beer, cider, wine, and mead. Understanding the relationship between these parameters and their impact on the brewing process is the key to creating the perfect brew.

An anecdote on the importance of water for Belgium beer brewing

Once upon a time, nestled in the picturesque countryside of Belgium, there was a centuries-old monastery known for its exquisite beer brewed by a community of dedicated monks. These monks, with their meticulous attention to detail and unwavering commitment to their craft, had a unique way of selecting water for their beer brewing process.

Legend has it that every year, during the season of cherry blossoms, the monks embarked on a quest to find the purest water source for their brewing needs. They believed that the quality of water played a vital role in creating the distinct flavors and aromas that made their beer exceptional.

The journey began with a procession of monks, clad in their traditional brown robes, carrying antique wooden buckets. They ventured deep into the dense forest surrounding the monastery, their footsteps muffled by the carpet of fallen leaves. Guided only by the sound of flowing water and the whispers of the wind, they sought out hidden springs and bubbling brooks, each with its own unique character.

As they discovered a potential water source, the monks would gather around, forming a circle, and perform a ritual of observation and contemplation. One by one, they would take turns carefully scooping water from the stream into their wooden buckets. Then, with an air of reverence, they would raise their buckets to the sky, allowing the sunlight to illuminate the liquid within.

Silence would envelop the group as they examined the water’s clarity and color, searching for telltale signs of purity. They sought a pristine translucence, an absence of impurities, and a subtle shimmer that indicated a harmonious balance of minerals. The monks believed that the water’s appearance reflected the hidden essence of the land it flowed through.

After the inspection, the gathered monks would engage in a spirited debate, sharing their observations and opinions. They spoke of the water’s taste, debating the presence of mineral notes and the level of softness on their palates. Their discussions often lasted well into the night, fueled by their deep passion for brewing.

Finally, a consensus would be reached. One water source would be chosen as the year’s most promising, and the monks would make their way back to the monastery, their buckets brimming with the precious liquid. This sacred water would then be combined with carefully selected grains, hops, and yeast, transforming it into a brew that would delight the senses of those fortunate enough to savor it.

For generations, the Belgian monks’ meticulous selection of water played an integral role in the creation of their revered beer. Their commitment to finding the purest source was a testament to their dedication to their craft and the belief that every element, no matter how seemingly insignificant, contributed to the creation of something truly extraordinary. Today, their legacy lives on in the world-renowned Belgian beers that continue to captivate beer enthusiasts around the globe.

Conclusion

The importance of understanding TDS and water hardness levels when brewing cannot be overstated. TDS and water hardness levels can have a significant impact on the brewing process and outcome, affecting taste, yeast performance, aging, pH and more. Understanding the desired TDS and water hardness levels for the type of beverage you are brewing is essential for producing a high-quality product. To ensure desired levels, brewers must take steps to measure and adjust TDS and water hardness levels when necessary.

Testing TDS and water hardness levels is not difficult and can be done using simple tools and equipment. Different testing methods are available, such as conductivity meters and water hardness test strips, that are easy to use and provide accurate results.

Brewers should also be aware of the different ways to adjust TDS and water hardness levels, such as adding minerals or chemicals, and of the potential impact of oversaturation and under-saturation.

In beer brewing, TDS and water hardness levels can have a significant effect on grain absorption rates, hop utilization, and beer clarity. For cider brewing, TDS and water hardness levels can have an effect on the tartness of the cider and the apple flavour.

With wine brewing, juice hardness and TDS levels can influence the flavour of the wine, and different types of wines can benefit from different levels of water hardness. Finally, when making mead, TDS and water hardness levels can influence fermentation and honey flavour and aroma, as well as mead clarity.

Finally, brewers should also be aware of the difference between TDS and specific ions, and of the importance of alkalinity and acidity when brewing.

Understanding these factors can help brewers to adjust and optimize their TDS and water hardness levels to achieve the desired outcome in their brews. Overall, taking the time to understand and assess the impact of TDS and water hardness levels is key for producing high-quality beer, cider, wine, and mead.