Apple juice and cider can be affected by a variety of microbes during different stages of their production. I am a microbiologist by education, so this topic is of particular interest to me!

These microbes can originate from the apples themselves, the equipment used for processing, the water, or the environment in which the apples are processed and the cider is fermented.

There are many microorganisms vying for a piece of the juicy apple pie.

The main questions that arises is: What are the potential contaminating microbes in cider brewing? How do we test for them? And how do we avoid them?

Cider spoilage is primarily instigated by a range of bacteria and wild yeasts, which can alter its flavor, aroma, and overall quality. The major culprits include Acetobacter, Lactobacillus, wild yeasts like Brettanomyces, but also various molds and bacteria such as Klebsiella and Bacillus species.

In this post, we’ll dive deep into the microbial world and discover which organisms can play spoiler to your brew.

What has Infected my Cider?

Here is an overview of some of the main microbes that may contaminate your apple juice and cider:

Before Fermentation:

- Acetic Acid Bacteria (AAB): Such as Acetobacter and Gluconobacter species. These bacteria can oxidize ethanol to acetic acid, resulting in vinegar flavors. They typically require oxygen to function effectively.

- Lactic Acid Bacteria (LAB): Such as Lactobacillus, Leuconostoc, and Pediococcus species. They can produce lactic acid and other compounds, which can affect the taste of the juice.

- Wild Yeasts: Such as Candida, Pichia, and Hanseniaspora. They can compete with desirable yeasts and produce off-flavors.

- Spoilage Bacteria: Such as Enterobacteriaceae. They can produce off-flavors and aromas in juice.

During Fermentation (When Turning Apple Juice into Hard Cider):

- Saccharomyces cerevisiae: This is the primary yeast used for alcoholic fermentation. While it’s desirable for fermentation, contamination with wild strains can lead to inconsistent flavors.

- Non-Saccharomyces Yeasts: Such as Metschnikowia, Brettanomyces, and Torulaspora. While some can contribute to complexity and desirable flavors in small amounts, others can produce off-flavors.

- Lactic Acid Bacteria (LAB): Can continue to be active during fermentation, potentially leading to lactic acid production and other flavor changes.

- Acetic Acid Bacteria: If exposed to oxygen during fermentation, they can produce vinegar flavors.

After Fermentation:

- Brettanomyces: Often referred to as “Brett,” it’s a wild yeast that can produce funky or barnyard flavors in cider. Some producers intentionally use Brett for complexity, but in many cases, it’s seen as a flaw.

- Lactic Acid Bacteria: Can continue to affect the cider, leading to potential spoilage or souring if not desired.

- Acetic Acid Bacteria: If the cider is exposed to oxygen post-fermentation, these bacteria can convert alcohol to acetic acid, giving a vinegar taste.

- Film Yeasts: These yeasts can form a film on the surface of the cider if exposed to air. They can produce off-flavors and compromise the quality of the cider.

1. Yeasts Gone Wild: Non-Saccharomyces Wild Yeasts

When we talk about fermentation, the first thing that comes to mind is yeast, specifically, Saccharomyces cerevisiae. But not all yeasts are created equal. There are several wild yeasts that can introduce themselves into your cider.

These include species like Brettanomyces, Candida, and Pichia. These wild yeasts can outcompete the intended Saccharomyces you have added to your cider, leading to off-flavors and undesirable characteristics in the final product.

The Ecology of Non-Saccharomyces Yeasts

These wild yeasts thrive in the orchard environment. They’re present on the fruit skin, in the soil, and in the air.

During the juicing process, when apples are pressed and crushed, these yeasts can easily find their way into the juice. They thrive on sugars, and given the right environment, can multiply rapidly.

How to Counteract Them: One way to keep these wild yeasts in check is to ensure a good pitch rate of your preferred yeast strain. This means introducing a high cell count of your chosen yeast to the must, ensuring they outcompete the wild strains. Additionally, good sanitation practices go a long way.

2. Mold: The Furry Invader

Mold is another common contaminant in cider brewing. While some molds are beneficial and used in food production (think blue cheese), the ones that find their way into cider are typically unwanted.

The Ecology of Mold

Mold spores are omnipresent. They float in the air, waiting for the right conditions to sprout. Moist environments with organic matter are perfect breeding grounds for mold.

When it comes to cider making, if your juice sits too long before fermentation begins or if there’s any contamination during the process, you could see mold growth.

The spores are definitely in your juice, even if pasteurized, but they will not hatch unless the conditions allow them to.

One important condition to be met is the presence of oxygen, so keeping your fermentation vessel airtight is crucial.

How to Counteract Them: Using fresh juice and ensuring fermentation begins promptly can help. Moreover, a sealed fermentation vessel that limits the amount of oxygen will deter mold growth.

3. Lactic Acid Bacteria: Double-Edged Microbes in Cider Brewing

Lactic acid bacteria (LAB) may have a reputation as unwanted intruders, but they play a dual role in cider brewing.

While their presence can lead to undesirable sourness, they also have a beneficial side that can be harnessed for specific cider profiles.

The Ecology of Lactic Acid Bacteria

LAB are omnipresent – found on the fruit skin, lingering in the environment, and even residing on our skin. Their primary function is the conversion of sugars into lactic acid, causing a drop in pH and introducing a tangy taste to the end product.

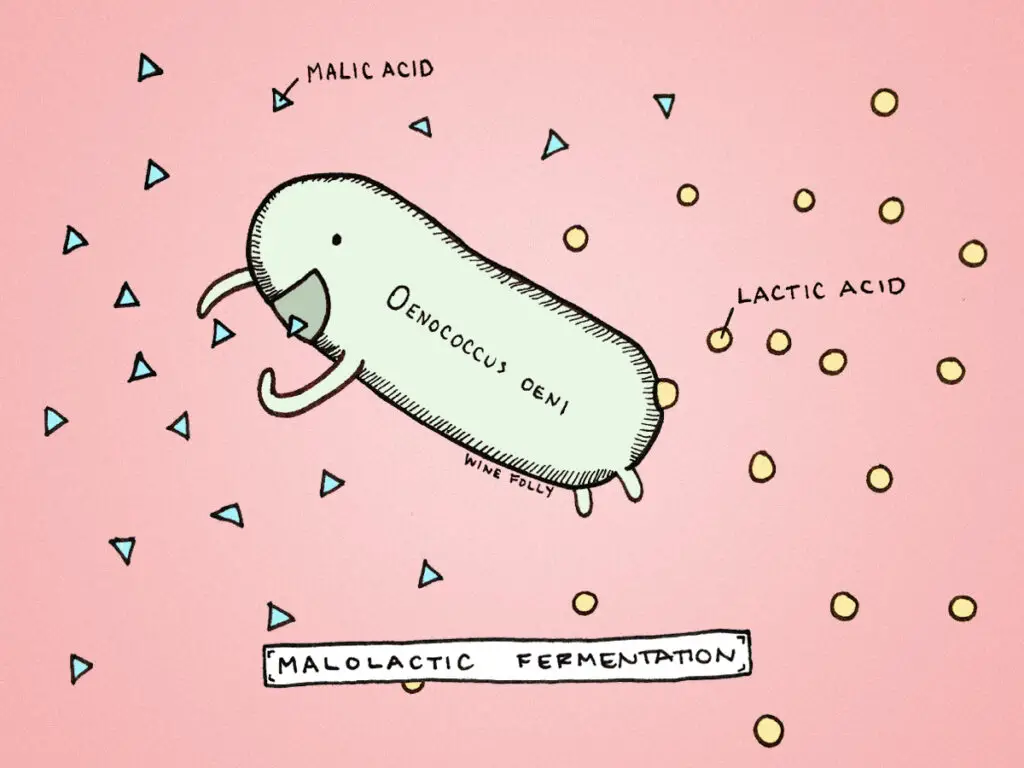

Beneficial Role in Cider Making: Malolactic Fermentation

Apart from their reputation as souring agents, LAB, specifically species like Oenococcus oeni, can be intentionally introduced for malolactic fermentation (MLF).

MLF is a secondary fermentation process wherein malic acid, a sharp tasting acid naturally found in apples, is converted to the softer and rounder tasting lactic acid.

This not only reduces the sharp acidity of the cider but also introduces complex flavor profiles, enriching the overall cider experience. Many traditional and artisanal ciders use MLF to achieve a smoother and more palatable finish.

Managing LAB in Cider Brewing

Counteracting Unwanted LAB: Good sanitation practices cannot be stressed enough. It is vital to clean and sanitize all equipment and materials that come in contact with the cider.

Campden tablets, containing potassium or sodium metabisulfite, can be used pre-fermentation to inhibit unwanted bacterial growth, ensuring that only the desired yeasts and bacteria contribute to the fermentation process.

Encouraging Beneficial LAB: For those looking to harness the benefits of MLF, specific LAB strains can be introduced into the cider post-primary fermentation. Monitoring temperature, pH, and nutrient levels can also help in ensuring successful MLF, resulting in a cider with depth and character.

While LAB can be viewed as contaminants, understanding and managing their presence can be the key to crafting unique and high-quality ciders.

Whether one aims for the crispness of a purely apple-derived drink or the layered nuances of MLF-treated cider, LAB is an essential player in the cider-making journey.

4. Acetic Acid Bacteria: Turning Cider into Vinegar

No discussion about potential contaminants in cider brewing would be complete without mentioning acetic acid bacteria (AAB).

The conversion of ethanol (ethyl alcohol) to acetic acid by AAB bacteria such as Acetobacter involves a two-step process:

- Oxidation of Ethanol to Acetaldehyde:

Ethanol + O2 → Acetaldehyde + H2O

- Oxidation of Acetaldehyde to Acetic Acid:

Acetaldehyde + O2 → Acetic Acid

Acetobacter species are obligate aerobes, meaning they rely on oxygen to perform their metabolic activities.

Notice that the presence of oxygen is essential for the oxidative transformation of ethanol to acetic acid.

While lactic acid bacteria might give your cider an unintentional sour kick, acetic acid bacteria can take it a step further, transforming your carefully crafted brew into something resembling vinegar. Which we are not usually interested in…

The Ecology of Acetic Acid Bacteria

Acetic acid bacteria comprise several genera, including Acetobacter and Gluconobacter. These aerobic bacteria thrive in environments where there’s oxygen, converting ethanol into acetic acid in the process.

The result? Your cider takes on a sharp, vinegary note. If you’ve ever had a cider that tasted surprisingly like apple cider vinegar, there’s a good chance acetic acid bacteria were at play.

This group of bacteria is naturally present in the environment. They are often found on the surface of fruits, including apples, and can be particularly prevalent if the fruit has been damaged or overripe.

This makes the juicing process a critical point of potential contamination. Once inside, if given oxygen, they can quickly start converting the alcohol in your fermenting brew into acetic acid.

How to Counteract Them: The battle against acetic acid bacteria begins with a stringent selection of your fruit. Ensure that the apples are in good condition and wash them thoroughly before juicing.

Given that AAB thrives in the presence of oxygen, it’s vital to minimize the cider’s exposure to air. Using an airlock during fermentation, ensuring containers are full to minimize headspace, and avoiding unnecessary agitation of the cider can significantly reduce the risk.

Additionally, maintaining a good fermentation temperature can ensure that the yeast remains active and outcompetes the AAB.

One of my most memorable (and not in a good way) brewing experiences involved a batch that had been invaded by acetic acid bacteria. The sharp, unmistakable tang of vinegar was a far cry from the crisp, apple-forward cider I had envisioned.

It was a stark reminder that even the smallest oversight, like not ensuring a proper seal on the fermentation vessel, can have significant consequences in the world of brewing. Always be diligent, fellow brewers, and keep those unwanted microbes at bay.

Other Bacterial Culprits in Cider Brewing

While we’ve discussed some major microbial culprits, cider brewing has a whole gamut of potential bacterial interlopers waiting to make their mark on your beverage.

Each of these bacteria interacts with apple juice and cider in unique ways, with varying impacts on the final product.

Many of these species, shown in the table below, are rare as they do not fare as well in cider as LAB and AAB or spoilage yeasts do, but they are a real concern for some cider makers and can even lead to dangerous infections.

Potential Bacterial Contaminants in Cider:

| Bacterium | Likelihood of Contamination | Symptoms on Cider | Prevention |

|---|---|---|---|

| Escherichia sp. | Low | Off-flavors, potential spoilage | Proper sanitation, pH control |

| Klebsiella sp. | Low to Moderate | Unpleasant odors, gas production | Avoid using damaged fruit, pH control |

| Bacillus sp. | Moderate | Off-flavors, spoilage | Thoroughly wash apples, proper sanitation |

| Staphylococcus sp. | Low | Potential spoilage, off-flavors | Avoid human contamination, proper sanitation |

| Acetobacter | High | Vinegar taste | Minimize oxygen exposure, use of airlocks |

| Alycylobacillus | Moderate | Off-flavors, spoilage | Pasteurization, pH control |

| Clostridium | Low | Gas production, potential spoilage | Avoid using damaged fruit, proper sanitation |

| Gluconobacter | High | Sourness, off-flavors | Minimize oxygen exposure |

| Lactobacillus | High | Sourness | pH control, good sanitation practices |

| Leuconostoc | Moderate | Off-flavors, potential spoilage | pH control, good sanitation |

| Saccharobacter | Low | Unpleasant odors, gas production | Proper sanitation, avoid using damaged fruit |

| Zymomonas | Moderate | Gas production, off-flavors | pH control, fermentation temperature monitoring |

| Zymobacter | Low to Moderate | Off-flavors, spoilage | Good sanitation practices, pH control |

As the list above indicates, the world of apple cider microbiology is vast and varied. Over the years, I’ve encountered a few of these bacterial guests in my brews.

Recognizing the symptoms early and having preventive measures in place has been vital in ensuring consistent quality in my cider. Remember, understanding the microbial landscape is half the battle in brewing!

How to Diagnose Contaminations in Cider Brewing

Diagnosing contaminations in apple juice or cider involves a combination of sensory evaluations, visual inspections, and laboratory tests. Here’s a detailed guide on how to diagnose each of these contaminations:

1. Sensory Evaluations

Taste and Smell: Off-flavors and aromas are often the first indicators of contamination. Training your palate can help identify specific microbial faults.

- Vinegar: Sharp acidic taste and smell indicates acetic acid bacteria contamination.

- Buttery: Diacetyl can be produced by some lactic acid bacteria, giving a buttery taste.

- Barnyard/Funky: Brettanomyces can give a characteristic barnyard or horse blanket aroma.

- Rotten or Putrid: Spoilage bacteria, like Enterobacteriaceae, can give such odors.

2. Visual Inspections

- Film or Pellicle: A thin film on the surface suggests film yeasts or bacterial pellicle.

- Haziness: Sudden unexpected haziness can indicate bacterial contamination.

- Sediment: Unexpected sediment can be a sign of microbial activity, especially if it’s active or bubbly.

3. Laboratory Tests

Microscopy: A microscopic examination can help identify yeast and bacterial cells’ presence and morphology.

- LAB (lactic acid bacteria) often appear as rod-shaped bacteria.

- Acetic acid bacteria might appear as short rods or ovoid cells.

- Yeast cells, depending on the species, appear as small ovals.

- pH Measurement: A drop in pH can suggest lactic acid bacterial activity, especially if it’s unexpected or unexplained by other factors.

- Acetic Acid Testing: If there’s a suspicion of acetic acid bacteria, testing for acetic acid levels can confirm their activity.

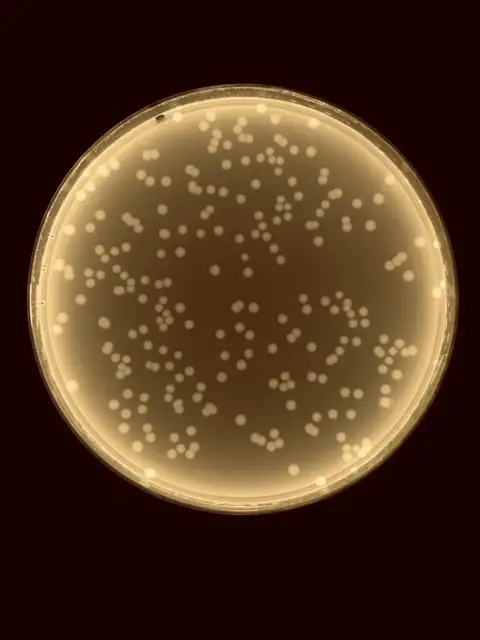

- Culture Methods: Plating out a sample on selective media can help identify specific microbes.

- MRS agar: For lactic acid bacteria.

- YPD agar: For general yeast and mold.

- GYP agar: Can be used for acetic acid bacteria.

- Gas Production: Some contaminations, especially certain bacteria, can produce gases during their metabolism. If your container shows unexpected pressurization, it could be a sign.

- Advanced Methods:

- PCR and DNA sequencing: These are more sophisticated methods to identify specific strains of bacteria or yeasts. If there’s a recurring problem, these methods can help identify and track the source of contamination.

- Metabolite profiling using GC-MS or LC-MS: To analyze and identify the metabolites (like organic acids, esters, and alcohols) in your cider, which can provide clues about the types of microbes present.

4. External Sources

- If you’re unable to diagnose contamination in-house, consider sending a sample to a specialized laboratory that handles beverage testing. They’ll have advanced tools and expertise to pinpoint the issue.

Prevention and Management:

While diagnosis is crucial, prevention is always better than cure. Ensure:

- Proper sanitation of equipment.

- Using quality ingredients, including well-treated water.

- Proper handling and storage of raw materials and finished products.

- If fermenting naturally, ensure a healthy population of desired microbes to outcompete potential contaminants.

Remember, not all microbes are undesirable. Some can add complexity and character to ciders when managed correctly. The key is to understand, identify, and manage them to produce the desired final product.

Avoiding Oxygen is Crucial

Because many of the spoilage organisms require oxygen, or at least grow faster when they have the possibility of using oxygen, it is crucial to prevent oxygen from coming into contact with your brew during fermentation.

Avoiding Oxygen To Prevent Mold Growth in Fermentation

Oxygen Requirements for Mold Growth

Molds are aerobic microorganisms, which means they require oxygen for growth. In the absence of oxygen, molds cannot thrive or reproduce. Fermentative yeasts, like Saccharomyces cerevisiae, consume sugars and produce alcohol in an anaerobic environment, making the environment even less hospitable for molds.

Competitive Exclusion

During fermentation, when conditions are anaerobic, yeasts dominate. They rapidly consume the available nutrients, leaving little for other microorganisms, such as molds. The high yeast population and the rapid decrease in available nutrients make it very difficult for mold spores to germinate and grow.

Production of Alcohol and CO₂

As fermentation progresses, yeasts produce ethanol (alcohol) and carbon dioxide (CO₂). Ethanol is a potent antimicrobial agent and can inhibit the growth of many microorganisms, including molds. The CO₂ production can also create a protective blanket over the fermenting wine, pushing out oxygen and further creating an environment where molds struggle to establish themselves.

Change in pH

Fermentation can lead to a decrease in pH (increase in acidity). Many molds prefer slightly acidic to neutral pH for optimal growth. A drop in pH during fermentation can create conditions less favorable for mold growth. This is why I always measure the pH regularly during fermentation.

Sensitizing Agents

In wine fermentation, other compounds may be produced or are naturally present, which can work synergistically with ethanol to make the environment even more hostile for mold growth.

Avoiding Oxygen To Limit Bacterial Growth in cider fermentation

Oxygen’s Role in Bacterial Growth

In cider fermentation, just as in wine, the introduction of oxygen post-fermentation can promote the growth of spoilage bacteria. Many unwanted bacteria, particularly those that spoil cider, are aerobic and require oxygen to thrive. By minimizing oxygen exposure, the conditions become less conducive for these bacteria to multiply.

Competitive Exclusion by Yeasts

The primary yeast used in cider fermentation, typically strains of Saccharomyces cerevisiae, rapidly consumes available nutrients.

This dominant consumption means that undesirable bacteria have fewer resources to support their growth. By ensuring a robust yeast fermentation, cider producers can limit the opportunity for bacterial contamination.

Production of Alcohol and CO₂

As the yeast ferments the apple sugars in cider, they produce ethanol and carbon dioxide. The increasing alcohol concentration acts as a deterrent to many spoilage bacteria, while the produced CO₂ can create a protective layer, displacing oxygen and further discouraging aerobic bacterial growth.

Change in pH

The fermentation process can also result in a drop in pH, creating a more acidic environment. This increased acidity can inhibit the growth of many spoilage bacteria, as most prefer neutral to slightly acidic conditions.

Presence of Organic Acids

Cider, being made from apples, contains a variety of organic acids, such as malic acid. These acids can act synergistically with ethanol, creating an environment that’s even more hostile to bacterial growth.

Post-Fermentation Considerations

In the wine and cider industry, it’s not just during fermentation that oxygen exclusion is crucial. Post-fermentation, wine can be susceptible to spoilage by bacteria (like acetic acid bacteria) and other unwanted yeasts, which can grow even in the presence of alcohol. Keeping oxygen out of the equation prevents these spoilage organisms from thriving and protects the wine’s flavor, aroma, and overall quality.

By understanding and managing the risks associated with oxygen exposure during and after fermentation, cider producers can maintain the quality and taste of their product, providing a better experience for consumers.

Conclusion: Defending Your Brew Against Microbial Marauders

As we’ve seen, cider making is a journey filled with potential pitfalls caused by unwanted microbes. While these organisms are a natural part of the environment, keeping them in check ensures that your cider retains its intended flavor profile.

Key Takeaways:

- Wild yeasts like Brettanomyces can introduce off-flavors.

- They are naturally present on fruit skins and in the environment.

- Mold spores float around, looking for moist organic matter to grow on.

- Lactic Acid Bacteria can cause an unwanted sour profile in ciders.

- Sanitation is the best defense against these unwanted guests.

- Ensuring a good pitch rate can outcompete wild yeasts.

- Using fresh juice and starting fermentation promptly limits mold growth.

- Campden tablets can help knock back unwanted bacteria.

- Cider is a balance of science and art, with a little bit of microbiology thrown in.

- Always be vigilant and mindful during the brewing process to achieve the desired results.

I’ve been brewing for years, and each batch teaches me something new. Respecting the microorganisms, both wanted and unwanted, has been essential.

When I experienced my first batch “tainted” by wild yeast, I realized the importance of cleanliness and vigilance. However, it did turn out drinkable after all…

For all the brewing enthusiasts out there, always remember: knowledge is power, especially in the microbial world. Happy brewing!