As a brewer, you may have come across the term “pectic enzyme” and wondered what it is and what it does. Pectic enzyme (also called pectinase) is an important ingredient in the brewing of cider and wine.

Pectic enzyme is a type of enzyme that breaks down pectins. Pectins are found in the cell walls of fruits and vegetables and are responsible for giving them their structure, but it also makes your hard cider, wine, melomel or fruit beers hazy!

In this post I will provide some tips for using pectic enzyme to get the best results. When to add pectic enzyme, and what factors are important for the enzyme to function optimally.

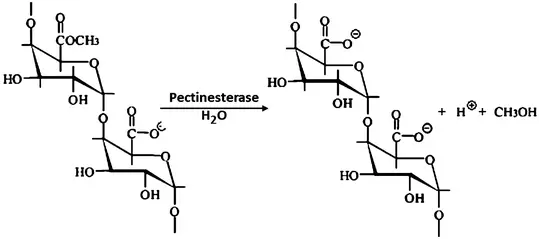

When pectinase breaks down the pectins, it makes the fruit or vegetable softer and easier to juice as it helps pectin to “dissolve” in water.

This is why pectic enzyme is often used in brewing, as it helps to break down the fruit during juicing, making it easier to extract all juice.

What Is Pectin And What’s Wrong With It?

Pectin is a type of carbohydrate found in the cell walls of fruits and vegetables. It is responsible for the gel-like texture of jams and jellies and is also used as a thickening agent in many other foods.

Pectin is made up of long chains of sugar molecules, and is classified as a soluble fiber.

Most fruits and vegetables contain some amount of pectin, but some are higher in pectin than others. Citrus fruits, apples, strawberries and plums are particularly high in pectin.

Pectin is also used as a food additive. It is added to jams and jellies to give them their characteristic gel-like texture. It is also used as a thickening agent in many other foods, including salad dressings, sauces, and baked goods.

There is nothing wrong or dangerous about pectins, on the contrary, as a dietary fiber it can be quite healthy to consume.

But it does make our brew look cloudy, which is not always what you want!

What Is Pectic Enzyme?

Pectic enzyme, or pectinase, is an important ingredient in cider brewing, cider-making, and wine-making. It breaks down pectins, which are long chain carbohydrates that can cause haze or sedimentation in finished products.

Pectic enzyme also helps to release fruit flavors and aromas during fermentation.

That’s where pectinase comes into play:

It helps break down the pectin found in apples and other fruits, which can cause a cloudy or hazy appearance in your finished product.

Using pectic enzyme during fermentation will help reduce this issue by breaking down the pectin into smaller molecules that are more easily dissolved in liquid. This makes for a clearer, brighter-looking cider with better flavor and aroma characteristics.

The amount of pectic enzyme needed depends on how much fruit you use when making your cider; if you’re using fresh apples or other fruits, then you may need to add more than if you were using juice concentrate or frozen fruit puree.

You should also consider how ripe the fruit is; overripe fruit contains higher levels of pectin than underripe ones do, so adding extra enzyme may be necessary if yours falls into this category.

It’s important to note that while adding too little won’t have any adverse effects on your brew, adding too much could lead to off flavors like cardboard or wet paper due to excessive breakdown of proteins and tannins from the apple skins and seeds respectively.

As such, it’s best to follow instructions closely when measuring out doses for each batch of cider you make!

In addition to helping clarify your final product, using pectic enzyme can also speed up fermentation time since less energy needs to be expended breaking down larger molecules before yeast can begin doing their job properly, resulting in quicker turnaround times between batches.

Some brewers find that they get better results with certain types of ciders (like those made with wild yeasts) when they use enzymes alongside them during fermentation as well; however, this isn’t always necessary depending on what type of brew you’re trying to create.

Using pectic enzyme in cider brewing is an important step to ensure the desired clarity and flavor of your hard cider. Next, we’ll discuss how to use pectic enzyme correctly when making cider.

Main Takeaway: Pectic enzyme is an important ingredient in hard cider brewing, as it helps break down pectin found in apples and other fruits to create a clearer, brighter-looking product with better flavor and aroma characteristics. It’s important to measure out doses accurately when adding the enzyme, as too much can lead to off flavors while too little won’t have any adverse effects. Pectic enzyme can also speed up fermentation time by reducing the amount of energy needed for yeast to do their job properly.

Why Use Pectic Enzyme in Cider Brewing?

Pectin is a naturally occurring polysaccharide in fruit that is responsible for the gel-like texture in jams and jellies. When brewing cider, pectins can cause the beverage to become cloudy and less flavorful.

Pectic enzyme helps break down these pectins, resulting in a clearer, tastier drink with more pronounced flavors and aromas. If you’re looking to brew the best possible cider at home, using pectic enzyme is a simple way to improve your results.

Improved Flavor and Aroma Profiles

Pectic enzyme helps break down complex molecules found in fruit juices used for brewing hard cider or wine into simpler components that contribute to improved flavor and aroma profiles. This process also helps reduce off-flavors caused by certain compounds present in fruits such as apples or grapes, resulting in a more balanced final product.

Enhanced Clarity and Color

Pectic enzyme is effective at breaking down suspended particles found within fruit juice which can cause cloudiness when fermented into hard cider or wine. By adding pectic enzyme during the fermentation process, these particles will be broken down resulting in an improved clarity of the finished product along with brighter colors due to less sediment being present.

Increased Shelf Life

One major benefit of using pectic enzyme while brewing hard cider or wine is its ability to help stabilize it over time by reducing any potential hazes caused by suspended particles still present after fermentation has completed.

This allows for a longer shelf life without sacrificing quality since there will be fewer particles available for spoilage organisms to feed on over time compared to if no pectic enzymes were added during the brewing process.

How long does it take for hard cider to clear on its own?

It is also important to remember that there are several other factors that lead to a cloudy cider, so not only pectin will make your cider hazy! However, pectin haze is clearly the most persistent one. Yeast is the second most common cause of cloudy cider, next after pectin, and the yeast eventually clears out when it is done fermenting and dies off.

Cider will eventually clear off on its own to some extent as pectinases are found naturally in fruit and are produced (as endopolygalacturonases) by many types of yeast. However this process is much slower, than what can be achieved with added pectinases.

Typically, hard cider will take a few weeks to a few months to clear on its own, depending on the specific recipe and method used. The exact time it takes for hard cider to clear can vary, so it’s important to check on it regularly and bottle it when it reaches the desired level of clarity.

It’s also worth noting that some ciders may not clear completely on their own, in which case a clarifying agent or fining agent may be used to help remove any remaining haze or particles.

There are several factors that can affect the rate at which wine and hard cider clear, including the type and amount of yeast used, the temperature at which the fermentation process takes place, the presence of any additional ingredients or additives, and the type of clarifying agents or fining agents used.

In general, warmer temperatures and the use of certain types of yeast can accelerate the clearing process, while cooler temperatures and the use of certain clarifiers or fining agents can slow it down. Additionally, the type and amount of solids present in the wine or cider, such as dead yeast cells, fruit particles, and other debris, can also affect the clearing rate.

How to Use Pectic Enzyme

Pectic enzyme is a key ingredient in cider brewing, and it’s important to understand how to use it correctly.

Pectin is a polysaccharide found naturally in fruits and vegetables that can cause cloudiness or haze in the finished product.

To avoid this, brewers add pectic enzyme during the fermentation process to break down these molecules into smaller pieces.

When using pectic enzymes, it’s best to add them early on before fermentation begins. This gives them time to work on breaking down any pectins present.

If you’re adding fruit or vegetable purees, consider straining out larger particles first so that the enzymes have an easier time working on smaller particles.

It’s also important to follow all manufacturer instructions when using enzymes – particularly with regard to dosage and contact time (the amount of time they should be left in contact with the substrate).

Generally speaking, more enzyme will be needed for harder-to-breakdown substrates like plums than harder ones like apples or pears.

Contact times may vary from several hours up to several days depending on what type of fermentable material you are dealing with and how much enzyme has been added.

Finally, it is important to ensure that your equipment is clean before adding pectic enzymes. Bacteria present can interfere with the effectiveness of the enzymes, so cleaning your equipment thoroughly beforehand will help you achieve optimal results when brewing hard cider.

Using pectic enzyme is an essential step in the hard cider brewing process, and understanding its purpose can help you create a better-tasting product. Next, let’s look at how to choose the right type of pectic enzyme for your needs.

How Much Pectic Enzyme Should I Add?

The general rule of thumb is to add 1 gram of pectic enzyme per gallon (3.8 L) of cider or fruit wine.

Too little pectic enzyme can result in a cider or fruit wine that is still cloudy and hazy.

Pectic enzyme is genrally safe to use and will not affect the flavor of your brew, so you can not add too much in terms of efficiency.

However, it is important to use the correct amount as instructed by the manufacturer of the specific pectic enzyme you are using!

Too much pectic enzyme can cause your brew to taste a bit flat and some people are allegic, so stick to the necessary amount and do not add more than that.

When to Add Pectic Enzyme?

Pectic enzyme should be added to the cider must before fermentation begins. This helps break down pectin, a naturally occurring substance in apples that can cause cloudiness and sedimentation.

Adding pectic enzyme early on before pressing the pulp of fruit into juice, also helps improve the yield of juice significantly!

It’s important to add pectic enzyme early in the cider making process, before fermentation as alcohol inhibits it.

It will also help you to distinguish the pectin haze from the haze caused by planktonic yeast cells floating around. This “haze” does depend on the yeast strain used, the temperature and time in the brewing process.

This will give the enzyme time to work on the pectins and prevent them from causing problems later on.

There are a few exceptions to this rule. Pectic enzyme can cause problems if it’s added to cider that’s already too cold.

This can happen if the cider is stored in a cool place before fermentation. In this case, it’s best to wait until the juice has warmed up a bit before adding pectic enzyme.

Pectic enzyme can also cause problems if it’s added to juice that’s already too acidic. This can happen if the fruit is too ripe or if the cider is made from concentrate e.g. when using a cider making kit.

In these cases, it’s best to wait until the juice has been diluted with water or has stabilized for a while before adding pectic enzyme.

However, in therey there are two main times you can add pectic enzyme during the cidermaking process:

Before fermentation when pressing the apples or in the beginning of primary fermentation. Adding it before fermentation will help break down the pectin haze faster and give you more juice yield overall.

In order for this technique to work properly, make sure that the temperature is right (room temperature) and that the pH is not extreme. You’ll also want to add the enzyme as early as possible in order give it enough time to do its job before the alcohol and low pH inhibits its activity.

Adding pectic enzymes after primary fermentation is another option which allows you preserve delicate apple aromas while still allowing for proper mashing of apples.

As a home brewer, it’s important to know when to add pectic enzyme in order to make the best cider possible. Each method of adding pectic enzyme (before or after pressing and fermentation) has its own set of benefits and drawbacks that you should take into account.

Make sure to use the proper technique for your desired outcome!

Main Takeaway: Pectic enzyme helps release all of the juice from the apples, giving you more apple flavor in your final product.

How Long Does it Take for Pectic Enzyme to Work?

The answer depends on a few factors, including the time of addition, the pH, alcohol concentration and temperature.

Generally speaking, pectic enzyme will take a few hours to work under optimal conditions if added at room temperature before fermentation.

However, you may not see the visual effect for a few days as the haze needs to precipitate first.

When using it on the ground fruits before pressing, leave it as close to room temperature as possible for a few hours.

Pectic enzyme releases methanol when hydrolyzing pectin, which can be harmful if consumed in large quantities.

Therefore, it’s important to use the proper amount of pectic enzyme when brewing – more is not always better!

However, the level of methanol will never be a problem as long as you do not concentrate it through distilling or “jacking”.

How long after pectic enzyme can you add yeast?

The amount of time that should elapse between adding pectic enzyme and adding yeast can vary depending on the specific recipe and brewing conditions, but generally it does not hurt the process to add them at the same time.

However, it is recommended to wait at least 15-30 minutes after adding pectic enzyme to allow it to work on breaking down the pectin.

This will help to ensure that the pectin is fully broken down and will not interfere with the fermentation process and that alcohol will not be produced to interfere with the enzyme.

After the pectic enzyme has had time to work, the yeast can be added according to the specific recipe.

But there ae no strict rules and even if you add the pectic enzyme a few days after the yeast, it will work fine but just less efficiently.

Pectic Enzyme in Fruit Beer Recipes

When making fruit beer, many brewers will add pectic enzyme to the recipe. Pectic enzyme helps to break down the pectins in fruit, which can make the beer cloudy.

The role of pectic enzyme in fruit beer brewing is similar to its role in cider production: breaking down the complex molecules found within the cell walls of fruits into simpler sugars that yeast can easily ferment into alcohol.

To use it effectively for beer brewing, simply add one teaspoon per gallon (4 liters) of wort prior to pitching your yeast starter culture – this will ensure that all those tasty aromas and flavors you want from your fruity additions remain intact throughout fermentation!

It is important to add pectic enzyme early in the brewing process, as it will not work once fermentation has started. Pectic enzyme is available in powder and liquid form.

Most brewers prefer to use the powder, as it is easier to measure.

When adding pectic enzyme to your recipe, it is important to follow the manufacturer’s directions. Generally, you will add 1 teaspoon (1 grams) of pectic enzyme powder per gallon (3.8 liters) of wort.

If you are using liquid pectic enzyme, follow the manufacturer’s directions for diluting it. Once you have added the pectic enzyme, stir it into the wort well.

Finally, while some people have tried using pectic enzyme for beer without success, other types of enzymes such as amylase or proteinases for removal of gluten for beer clarification purposes seem to work better.

How to Use Pectic Enzyme for Wine Making?

Pectic enzyme is an important component in wine making, as it helps to break down the pectins in fruit which can otherwise cause haze and other issues in the final product.

Adding pectic enzyme to your wine must be done carefully however, as too much can cause off-flavors and other problems.

Here are some basic guidelines on how to use pectic enzyme when making wine:

- Sanitize all of your equipment thoroughly before beginning.

- Add the pectic enzyme to your must (crushed fruit and juice) at the beginning of fermentation, and stir gently to distribute it evenly.

- Allow the fermentation to proceed as normal, and check the progress after a few days. If the pectins have not been sufficiently broken down, you can add a little more pectic enzyme and stir gently again.

- Once the fermentation is complete, rack (transfer) the wine off of the sediment and proceed with bottling or other storage as usual.

Thats it!

Does Pectic Enzyme Expire?

Pectic enzyme is a natural substance, so it will eventually expire. The good news is that it has a pretty long shelf life, and as long as it’s stored properly, it can last for years.

However, there are a few things to watch out for that can indicate that the enzyme is no longer effective.

One of the most obvious signs that pectic enzyme has gone bad is a change in color. If the enzyme is no longer a clear or white color, it’s probably time to replace it.

Another indication that the enzyme is no longer effective is if it has clumped together. If the powder has clumped into a hard mass, it’s no longer going to be effective in brewing or winemaking.

If you’re not sure whether or not your pectic enzyme has gone bad, the best thing to do is to give it a smell. If it has a sour or off smell, it’s probably time to replace it.

Pectic enzyme is an important ingredient in many brewing and winemaking recipes. This natural substance is derived from the cell walls of fruits and helps to break down complex carbohydrates into simpler sugars.

without it, many fruit beers and wines would be undrinkable. But does this enzyme have a shelf life?

And if so, how can you tell when it’s time to replace it?

Pectic enzyme is a natural substance, so it will eventually expire. The good news is that it has a pretty long shelf life, and as long as it’s stored properly, it can last for years.

However, there are a few things to watch out for that can indicate that the enzyme is no longer effective.

One of the most obvious signs that pectic enzyme has gone bad is a change in color. If the enzyme is no longer a clear or white color, it’s probably time to replace it.

Another indication that the enzyme is no longer effective is if it has clumped together. If the powder has clumped into a hard mass, it’s no longer going to be effective in brewing or winemaking.

If you’re not sure whether or not your pectic enzyme has gone bad, the best thing to do is to give it a smell. If it has a sour or off smell, it’s probably time to replace it.

Alternatives to Pectic Enzyme

Pectic enzymes are used in cider brewing to help break down pectins, which can cause haze and other issues with the final product.

There are a few different alternatives that can be used in place of pectic enzyme, depending on what you have available and what your preferences are.

One option is to use another type of enzyme, such as amylase or cellulase. These enzymes will also help break down the cell walls of fruit, but may not be as effective as pectic enzyme.

Gelatine

Gelatin finings are derived from animal products and work by binding with proteins in the liquid which causes them to sink to the bottom of the container.

This method works best when used after fermentation as it will cause some flavor loss if added too early.

To use gelatin finings, mix one teaspoon per gallon into warm water until completely dissolved then add it directly into your fermenter and wait a few days.

Isinglass

Isinglass is made from fish bladders (so not vegan!) and works similarly to gelatin finings but does not have any impact on flavor or aroma like gelatin does.

It also needs to be added prior to fermentation for optimal results but can still be effective when added afterwards as well.

To use isinglass, dissolve 1/2 teaspoon per gallon in warm water then stir gently into your brew prior to bottling or kegging.

Bentonite

Bentonite clay is a popular choice for clearing wines and ciders due its ability to bind with proteins without affecting flavor or aroma like other fining agents do. It should be mixed with warm water at a ratio of 1 tablespoon per gallon then stirred slowly into your brew prior bottling or kegging for best results.

The bentonite binds with proteins and other particles in the must and sinks to the bottom of the vessel. This clarification process makes the wine clearer and prevents off-flavors.

This helps to improve the extraction of color and flavors from the grapes during fermentation, but there is no reason why bentonite cannot also be used in cider brewing and for mead.

Egg Whites

Egg whites are an inexpensive way of clarifying beer, wine, and cider since they contain albumin which binds with tannins in the liquid causing them settle out over time resulting in clearer beverages without impacting taste or smell negatively like other agents do.

First, you’ll need to separate the whites from the yolks of several eggs.

Then, whisk the whites until they are foamy and add them to your wine. Allow the mixture to sit for 24-48 hours, stirring occasionally.

After this time, you should see the egg whites starting to form a compact layer on the surface of the wine. At this point, you can add the pectic enzyme and stir gently.

Allow the wine to sit for another 24-48 hours before racking it off the egg white sediment.

If you’re looking for a simple and effective way to clarify your wine, egg whites and pectic enzyme are a great option. Just be sure to give the mixture enough time to work its magic!

Be aware that many of these options are derived from animals and that will technically classify your brea as non-vegan if used!

Sparkolloid powder

Sparkolloid powder is a popular agent used for clearing beers, wines, and ciders due to its ability to bind with proteins quickly.

This results in clearer liquids within days instead of weeks like other agents require, making it ideal for those who need their beverages cleared quickly such as homebrewers.

To use this method, simply mix two tablespoons per gallon of warm water into your fermenter just before bottling or kegging.

Allow enough time (1-3 days) for the sedimentation process to complete itself properly resulting in crystal clear beverages.

Other methods of clearing wine and cider include cold stabilization (also known as cold crashing), and filtration.

Main Takeaway: When it comes to clearing beer, wine, and cider, there are a variety of options available. Gelatin finings, isinglass, bentonite clay, egg whites and sparkolloid powder are all effective agents that can be used for clarification without impacting flavor or aroma negatively. Each agent has its own advantages such as speed of clarity (sparkolloid) or lack of flavor loss (isinglass), so it’s important to research which one best suits your needs before use.

Common Mistakes When Using Pectic Enzyme in Home brewing?

Using pectic enzyme in homebrewing can be a great way to improve the flavor and aroma of your hard cider or wine. However, if not used correctly, it can lead to some common mistakes that could ruin your batch.

Not Adding Enough Pectic Enzyme to the Must: One of the most common mistakes when using pectic enzyme is not adding enough of it to the must (the mixture of fruit juice and water). If you don’t add enough pectic enzyme, then there won’t be enough enzymes present for them to break down all of the pectin molecules in your must. This will result in a cloudy cider or wine with poor clarity and color.

Not Allowing Enough Time for Fermentation to Completely Finish Before Bottling or Kegging The Cider/Wine: Another mistake is bottling or kegging too soon before fermentation has completely finished. If you bottle or keg too early, then residual sugars will remain which can cause over-carbonation leading to exploding bottles and foamy beer lines!

Not Monitoring pH Levels During Fermentation Process: Lastly, many brewers forget about monitoring their pH levels during fermentation process. Keeping an eye on pH levels throughout fermentation helps ensure that everything is going as planned.

It also allows you make adjustments if needed such as adding more acidity if necessary. Without proper monitoring, you may end up with a flat tasting product due to low acidity levels which could have been avoided had they monitored their pH levels regularly throughout fermentation process.

By avoiding these common mistakes when using pectic enzyme in homebrewing hard cider/wine, you can ensure that your final product tastes excellent.

When brewing hard cider at home, it is important to pay attention to the amount of pectic enzyme used, the length of fermentation time and pH levels during fermentation. If these steps are not taken into consideration, then the resulting product may not be as desired. Next we will look at how to properly use pectic enzyme in homebrewing.

Main Takeaway: Using pectic enzyme in homebrewing can be a great way to improve the flavor and aroma of your hard cider or wine, but it’s important to add enough enzyme, allow fermentation to finish before bottlingkegging, and monitor pH levels throughout the process. Doing so will help you avoid common mistakes that could ruin your batch and ensure that your final product tastes excellent.

Tips for Successful Use of Pectic Enzyme in Homebrewing?

It helps break down the complex carbohydrates found in fruit juice, which can lead to improved clarity and color of the finished product. Additionally, it increases shelf life by preventing spoilage due to oxidation. To ensure successful use of pectic enzyme in homebrewing, there are several important tips that should be followed.

Start with Clean Equipment: The first step when using pectic enzyme for brewing is making sure all equipment used throughout the process is clean and sanitized thoroughly. This will help prevent contamination from bacteria or wild yeast that could ruin your batch of hard cider/wine before fermentation even begins.

Use at least one gram per gallon (3.8 L) of must or wort when adding it at the beginning of fermentation when temperature is around 70–75 °F (21–24 °C). This will ensure that you get maximum benefit from using this product.

Measure Out Precise Amounts: When adding pectic enzyme to your must (fruit juice), it’s important to measure out precise amounts so you don’t over- or under-dose your mixture. Generally speaking, 1 teaspoon per gallon of must is recommended for optimal results but this may vary depending on the type and amount of fruit being used as well as other factors such as temperature during fermentation process etc., so make sure you do some research beforehand if possible!

Monitor pH Levels Regularly: During fermentation process, monitoring pH levels regularly will help ensure successful use of pectic enzyme in homebrewing since too high or low levels can affect how quickly sugars are converted into alcohols which ultimately determines taste profile at end result stage – something nobody wants! Adjustments may need to be made accordingly if necessary so keep an eye on things closely while fermenting!

By following these simple tips when using pectic enzymes for home brewing hard ciders/wines, brewers can expect improved flavor profiles along with enhanced clarity and color compared to batches brewed without them. Additionally, they may also experience increased shelf life due to prevention against oxidation spoilage.

Using pectic enzyme in homebrewing can be a great way to create a delicious hard cider or wine, but it is important to follow the tips outlined above for successful use of the enzyme. Next, we’ll look at how to store and preserve your pectic enzyme properly.

Main Takeaway: Using pectic enzyme in homebrewing can improve the flavor, clarity and color of hard ciderwine, as well as increase shelf life. To ensure successful use of pectic enzyme, it is important to start with clean equipment, measure out precise amounts and monitor pH levels regularly during fermentation.

Pectic Enzyme FAQs

Improved flavor and aroma profiles, enhanced clarity and color, as well as increased shelf life are just some of the advantages that come with using this important brewing ingredient.

Missing something? We have answered the most common questions about pectin degrading enzymes below!

Is pectic enzyme necessary?

Pectic enzyme is not necessary for making cider, but it can help to improve the clarity and flavor of your final product. This enzyme breaks down pectins in fruit, which can make your cider cloudy and cause off -flavors.

If you are having trouble with either of these issues, adding pectic enzyme may help, but some people just like a cloudy wine or cider and thats ok.

If you do not want to clear your cider or want to use other alternative clearing agents, then pectic enzyme is not necessary for you!

Can You Add Pectic Enzyme During Fermentation?

While it’s possible to add pectic enzyme during fermentation, it’s generally more effective to add it at the beginning of the process, before fermentation has started.

This allows the enzyme to work on the pectins for a longer period of time, resulting in a clearer cider. And it also prevents alcohol and too much acid build up from inhibiting the pectolase enzyme activity.

If you add it during fermentation, I would recommend adding twice the amount recommended by the manufacturer.

Can I Add Pectic Enzyme After Fermentation?

The short answer is yes, you can add pectic enzyme after fermentation. However, the alcohol in the cider will inhibit the activity of the enzyme, so you will need to add much more than you would prior to the brewing process.

If you’re adding pectic enzyme after fermentation, you’ll need to add enough to compensate for the alcohol. A good rule of thumb is to add twice as much pectic enzyme as you would during the brewing process.

So, if you typically use 1 gram of pectic enzyme per gallon (3.8 L) of cider, you would use 5 grams per gallon (3.8 L) when adding it after fermentation.

Do campden tablets affect pectic enzyme?

Campden tablets are a type of food-grade potassium or sodium metabisulfite that is used in the brewing and winemaking process to inhibit the growth of bacteria and wild yeasts. Pectic enzyme is a type of enzyme that is used in the brewing process to break down pectin, a substance found in fruits that can cause haze in finished beer.

Campden tablets do not affect pectic enzyme, as they are designed to inhibit the growth of microorganisms, not enzymes. It is safe to use campden tablets and pectic enzyme in the same batch of beer, and doing so can help to ensure that the beer is free of bacteria and wild yeasts, while also helping to break down the pectin to prevent haze.

However, it is important to note that campden tablets can release sulfur dioxide (SO2) when they are dissolved, and high levels of SO2 can have a negative effect on the activity of enzymes. Therefore, it is recommended to wait at least 15-30 minutes after adding campden tablets to allow the SO2 to dissipate before adding pectic enzyme.

This will help to ensure that the pectic enzyme is able to work effectively to break down the pectin. It is always best to consult a brewing guide or the instructions on the campden tablets and pectic enzyme to determine the appropriate amount of time to wait between adding the two.

Can You Use Too Much Pectic Enzyme?

While pectic enzyme is an important ingredient in cider brewing, as it helps to break down the pectin in the apples, which can otherwise make the cider cloudy. If added late in the process you will need to add quite a lot!

However, too much pectic enzyme can cause problems, such as making the cider taste a bit off and some people can show allergic reactions to the enzyme itself if too much is left in the final product.

Personally, I would never add more than 20 grams per gallon, but I do not know of anyone ruining their wine or cider by adding high amounts of pectic enzyme.

However, if you add it before fermentation you make it much easier and faster!

How is pectic enzyme made?

It is produced in microbes like bacteria or fungi or it is extracted directly from fruits like papaya peel. This means that pectic enzyme is technically vegan and safe to use for people who do not eat animals.

Where Can I Buy Pectic Enzyme?

If you’re looking to add pectic enzyme to your cider brewing process, you may be wondering where you can buy it. Luckily, pectic enzyme is widely available online and in many homebrew supply stores.

If you’re looking for a high-quality pectic enzyme, we recommend checking out the products show below:

Whether you’re a beginner or a seasoned cidermaker, adding pectic enzyme to your brewing process is a great way to improve the clarity and flavor of your final product.

So head to your local homebrew supply store or shop online and pick up some pectic enzyme today!

Conclusion

It helps to break down pectins in the fruit, which can otherwise lead to haze and other brewing problems.

When used properly, pectic enzyme can help you produce clearer, smoother ciders that are more enjoyable to drink!